Elirmnation of D-band in Raman spectra of double-wall

Elirmnation of D-band in Raman spectra of double-wall

carbon nanotubes by oxidation

S. Osswald ', E. Flahaut b, H. Ye ', Y.Gogotsi p*

MulerrbIs Schme

and Engbewatg D e p a H m i and A.J. Drexd Nanorechndogy hsai~ade,Drexel Uniwfsity.

3141 Chestnut Streei (383 CAT),PSl&&wkPA 19104, USA

h t r e Inrmttiv@rsi'Iairede Recherche et cPlngbieri&&S Mat6riaarx. UAgR CNRS 5085. Uniwr~itiPaul Sabath,118 Route & Narbam,

31062 Todollse, fiance

Iu this biter, we preseat m in situ Raman spactroscopy study of oxidation-inducedchanges in h e srru~tureand wmposrtion of

double-wall carbon nanotubes PWCNTs). Above 48!l @C,the i n e t y of the D band &ram to lw than 0.01% of the G hand

intensity, when meststld using the 780 nm Iaser mutation. Tlse D band was absent from the Raman spectra recorded with the

514.5 nm excitaiian. ~

~

~

analysis

t

r andi hiBtr.~tr.rnolufi.an

c

transmission dectron mimoscopy are used to explain the

abs& result&.We conelude that o a t i o n pravicb o pWcation M o d for the D W W wbicb leads to a sample t w t a h b g

tub@ having &y dean awfaw without digwded carbon.

O 2004 &vier B.V. All righrs reserved.

Double-wdl carbon nanoluh @W-

is the most

bask mmber of the multi-walled carbon nabtube

(MWCNT) family [l] which catl be prod& h significant quantities p]. T h e tubes consist of two concentric

cylindrical graphene layers and their range. of diameters

is comparable to that of singlewalled carbon nanotubes

(SWCNTj, Several methods for producing DWCNT

have been reported, such as oatdytic chemical mpom

de-tiw

(CCVD) [l-31, arc discharp 141 or heating

molecules ~ p ~ uia lS Wam T

~ [l.

Unfmtunauely, c~mmer&lIy viable methods such as

CYD 07 arc discharge l& to products which cofitain

cadyst partides and 'amorphous*carbon. The products

alsa contain same SWCNT and MWCNT along with

DWCNT. Of mume, the diameter distribution and also

the content of Merent tubes in the raw pmduct vary

between tbe different synthesis methods. There exists

no singh p d c ~ t i o nprocess whch would remove all

impurities and separate DWCNT from other types of

tubes. While catalyst particle6 can be eliminated by acid

treatments [1,6,g, the amorphous c a r h and the

unwanted SWCNT can also be removed by oxidation

in flowing or static air [l ,641. Thmnograuimetric analysis (TGA), which shows changes of mass during oxidation p r o m , has been used to determine the oxidation

pud5~8tionconditions [l 01.

However, TGA alone does not provide information

on what is m o v e d from the sample by oxidation.

Raman sp~trawopyprovides S powerhi method for

characterization of the carbon structure [f l]. S i m k

to the Raman spectra of S W W , D W W exhibit

three d u r & s t i c

bands: the tangential (vibrations

along the tube axis) stretching G mode (15001600 m-'),the D mode (-1350 cm-? and the radial

breathing mode RRM (100-400cm-') 111-141. While

the frequency of the RBM is inversely proportional to

the tube diameter, the tangential stretching mode weakly

depends on the diameter of the nanotube 1151. D band in

amorphous or disordered carbon is assigned to a double-resonance Raman effect in sp2 carbon [l61.The contribution of defects in the tube walls and other forms of

carbon, such as rings, to the D band is still not completely understood. Raman spe~trascopycan provide

real-time monitoring of changes in the sample's structure and composition.

In this Letter, we present the results of an in intu

R m a n spectroscopy study of oxidation of DWCNT

which were produced by a CCVD method. The goal of

the work was to select the oxidation conditions leadiig

to the removal of amorphous carbon by rnonitosing

the intensity of the D band in Raman spectra.

heating procedure was used for every reptition and

each time the experiments were stapped after reaching

the maximum temperature.

The TGA was performed with a SETARAM TAG24

thermobdme. In the TGA experiments, the sample

was heated in static air from 25 to 600 OC at 5 @Clmin

continuously up to $00 OC. To simulate the heating conditions of the in situ Raman study, 4min isothermaT

steps were performed at 400,420,430 and 440 "C slnd

S-&

steps

U S at~ 460 and 500 "C.The total h t ing time in the stepwise experimerlts with 5 "Clmin h a t ing rate was comparable to the continuous heating rate

of 3 "Clmin.

3. Results and discussion

The DWCNT were produced by the CCVD method

using a Mgl - ,CO# solid solution catalyst containing

molybdenum oxide with the elemental composition

M~.99C~o.m75M~o.mB

(21. The wpr~duoedCNTScontained a very low amount of amorphous carbon, present

only as deposits on some of the tubes' outer waU.

HRTEM observation of the sample showed 77%

DWCNTs, 18% SWCNTs and 5% TWCNTs. The &ameter distribution of the DWCNT ranged from 0.53 to

2.53 nm for inner tubes and from 1.2 to 3.23 nrn for outer tubes, while the diameters of the SWCNT reached

1.1-2.7 nm 14. The sample was heated in a Linkam

THMS 6QO heating stage in static air from 20 to

MO "C at S "Clmin. The sample was held for 4 min at

every measurement point. The stage was calibrated by

using the melting points of A$N03 (209 "C), Sn

(232"C),KN03 (334 'C), and Ca(OH)2 (580 "C). In

every case, the difference between the measured and

expected melting point did not exceed 2 "C.

The specm were acquired with a Raman micro spectrorneter (Renishaw 1Q00) using an Ar ion laser

(5 14.5 nm) and a diode kser (780 nm) in back-scattering

geometry. We used a 2Qx objective with a spot size of

-5 pm in diameter, which included a large number of

tubes, providing statistically reliable results. A low laser

power density was used on the sample (laser power

c2 mW) to avoid laser heating of the tubes. This low

power density was achieved by filtering andlor tiefocusing the laser beam at the sample surface. Spectra were

acquired with 50 O C steps in the range from 50 to

3% O C , followed by 25 O C steps from 350 to 400 OC

and concluded with 10 *C steps from 400 ta BOO O C .

After reaching the desired maximum temperature, the

sample was cooled dawn at 20 "Cl& until reaching

80 'C and then cooled at 10 "Ctmin to room temperature. The heatir@moling cycle was repeated I5 times

on different samples from two different DWCNT

batches to obtain statistically reliable data. The same

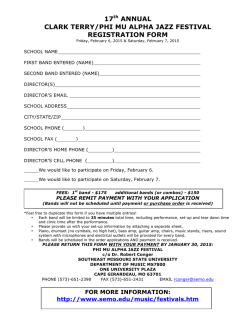

Fig. 1 shows the D and G band range of the Raman

spectra of DWCNT sample recorded during heating.

Prior to heating, the G band can be well fitted with

Lorentzian peaks at 1593 and 1568 cm-', and a broad

Gaussian peak at 1525 cm-' (Fig. 2a) for 514.5 nm;

Lorentzian peaks at 1592 and 1564 cm-', and broader

Gaussian peaks at 1548 and 15 19 cm-' for the 780 nm

laser wavelength. Note that only in the case of Fig. 2,

a baseline correction was used in the frequency range

10&700 m-' to correct the influence of the filter for

Fig 1. In situ Raman spectm%opy study of the changes in the D arid

G band of DWCNT during oxidation (514.5 nm h w &citation

wavelength).

Raman S h i i (cm")

Raman shift (cm")

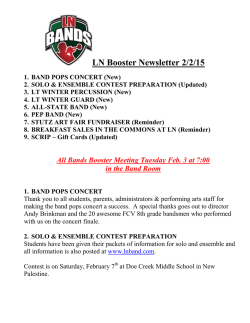

Fig. 2. Raman spectra dDWCNT using 780 and 514.5 nrn laser excitation obtained (a) before and (b) after oxidation. lntensities of the spectra have

been adjusted to improve presentation.

the Rayleigh peak to the spectra in the frequency range

from 0 to 200 cm-'. While the narrower Lorentzian

peaks are ascribed to the semiconducting nanotubes,

the broader peaks are attributed to the metallic tubes

[17,18] or overlapping of several peaks arising from

tubes with similar diameters.

In Fig. I, it can be shown that the D peak, which is usually attributed to disordered carbon, starts to decrease at

-430 "C until it completely disappears at around 510 "C.

This peak is present in the sample even if the amount of

disordered carbon is very low. D band in nanotubes

may also originate from defects in the tube walls and

was observed in some nanotube samples that did not contain amorphous carbon. For example, we observed it in

purified MWCNT samples. A linear downshift of all

peaks was observed with increasing temperature, but

the slope varies for different peaks. The value of the thermal shift was reported to be 0.03 C ~ - ' P Cfor SWCNT

[l 3,191. Our measurementsconducted on high purity natural graphite (G band at 1580 cm-')led to the value of

0.024 cm-'/"C. The present experiment for the DWCNT,

using 514.5 nm wavelength excitation, showed a downshift of 0.029 c r n - ' ~ "for

~ the 1568 cm-' peak and a value

of 0.026 c m - ' l " ~for the 1593 cm-'peak (Fig. 2b), which

are within the expected range.

Another important observation is that the intensity

changes of the D and G bands at high temperatures follow different trends. The initial decrease of the I d I G

ratio is mainly due to the increase of the G band inten-

sity. The intensity of the G band starts to increase at

.-v440 OC, soon after noticeable weight loss is recorded

on the thermogravimetric wrve (Fig. 3), and reaches a

maximum around 500 OC and then it decreases again

(Fig. 3). As seen in Fig 3a, the decrease in D band intensity omurs at temperatures 2&30 OC higher that the

increase in G band intensity in most experiments. An

explanation for the d y intensity increase of G band

may be the possible removal of hydrocarbons (the tutK

synthesis was conducted in a hydrogen-containing

atmosphere) and disordered carbon, which were shiefdhg the Raman signd from the as-received tubes. It is

supported by a significant weight Ioss observed in this

temperature range (Fig. 3b). Some variations in the temperature difference between the G and D band changes

o b w e d in our experiments rnay be due to a different

number or packing density of nanotubes as well as different amounts of amorphous carbon present within

the and@ area. On the other hand, there might be

some temperature e f f k t s on the mbond vibrations

which may s a c t Weerentry during hearing with respect

to the curvature and the influence of temperature on

the bond softening [20].The fact that the G band's absolute intensity starts to increase at about the same temperature as the D band decreases seems to support the

former hypothesis. Further BVidence is provided by the

fact that a higher intensity (206300%) of G band was

observed after cooling to room-temperature in every

experiment. When m already oxidized sample was used

(a)

.

o f 0 bond

4

-

4

E=

v***

$2' - * C

D

4

-

-

-=

4

1 . . ' 1 . . . 1 ' . . 1 " . 1 . ' . *

0

1 o o 2 0 0 9 0 0 4 0 0 ~ 8 0 0

Fig. 3. (a) Cornpmhn of intensity changes in the D and G bands

duriag oXidation (meawed with 5 14.5 am lam wavelength) md (b)

TOA curves obtained by heating a DWCMT srunpIe in air.

for the in situ Raman study, no i n m e of G band was

observed. In this case, there was na disordered carbon

w the tube surface which could influence the Raman

signal of the tubes.

Fig. 2 shows the Raman spectra taken at room-temperature before and after heating. This graph also demonstrates that the splitting of the G band is more

pronounoed after heating and that the shift of the peaks

due to heating is not completely reversible. This may

again be due to removal of amorphous carbon and the

most defective tubes. It has been reported that the G

band at 1590 cm-' does not depend on the tube diameter [IS]. Thus, its position should not change after oxidation of smaller tubes as a result of a decrease of their

contribution to the total intensity of G band. The lower

frequency component of the G band (peaks at or below

-1570 cm-') d e p d s on the diameter of the tubes. The

oxidation of the smaller tubes leads to a change in the

lower frequency peaks while the peak at 1590cm-'

shows only littie shift (Fii. 2). RBM show no significant

changes, thus tube size distribution have not been changed. This shows that tubes were not selectively oxidized

or damaged is our proms, in spite of the fact that up to

a 90% weight loss was observed in some experiments

(Fig. 3b).

The most noticeable effectwas the near complete disappearance of the disorder induced D band after oxidation (Figs. 1-3). Using the 514.5 nm laser, the D band is

not observd at all above 510 "C. For the 780 nm bw,

which produces the largest D band intensity, the IdlG

ratio decreases from 0.43 before beating to <0.0 15 after

oxidation, The experiments also show that complete Dband removal is possible at lower t e m p e r a m ( 3 5 6

400

by using a longer isothermal exposure time or

a slower heating rate. These results show that in the case

of DWCNT, the D band ariginata ody from the amorphous carbw in the sample (even if present only in low

amwnt) and not from the defects in tube walls. W e

the concentration of defects probably increases during

the oxidation, the disordered carbon and associated D

band, disappears. In similar experiments with CVD

MWNT of about I0 nm in diameter, the phenomenon

could not be observed after heating to 600 "C, when

amorphous carbon had been removed. In the case of

MWNTs, the D band probabIy originates primarily

from defects in the tube walls. AU the amorphous Wbon is oxidized at temperatures below 600°C as well

as some nanotubes. However, the oxidation under our

conditions has never eliminated all omotubes. The composition of the sample at tbe end ofthe measurement ds

pends on the analped spot, but comparison of RBM

modes before and after oxidation (Fig. 2) shows that

only insigniscant changes in the distribution of tube

diameters could be observed. Thus, removal of amorphow carbon is possible with minimal loss of tubes

and change in diameter distributions in the sample. This

cannot be explained by insufficient air supply; control

experiments with open or closed valves show that there

was no air shortage in the in situ Raman experiments.

Also, all catalytic material was oxidized forming primarily cobalt oxide, which produd bands at 475-680 cm-'

in the Raman spectra of nanotubes after oxidation (Fig.

2b). The positions of Rarnan bands of Co304reported

in literature are 182, 460, 505, 600 and 670 cm-'c211

and their relative intensities are in agxement with our

observations (the strongest band is at -680 cm"').

Fig. 4 shows TEM images of the DWCNT samples

before (a&), after oxidation (c,@ and after additional

acid treatment (e,O to remove catalyst particles from

the sample. Two images are shown for each sample at

low and high magdcation, respectively. Fig. 4b shows

that some amorphous carbon is present in the form of a

deposit in some places in the sample before oxidation; it

must be noted that Fi.4b is not representative of the

whole sample, which is mainly clean of amorphous carbon deposit. After oxidation (Figs. 4c and d), the disordered carbon is completely m o v e d and only catalyst

particles are left next to the nmotubm. The catalysts

were oxidized ta form Co304 as shown h Raman spectra (Fig. 2b), for which Raman peaks are strongly excited by the 514nm laser. These oxide particles are

larger than the initial nanometric metal catalytic partides due to caalescence and likely volume increase upon

oxidation. Also, the content of particles in the sample

(relative to the nanotubes) seems to increase after heating to 600 "C, This may be explained by oxidation of

some nanotubes in the sample as evidenced by significant weight loss observed in Fig. 3b.

While high-resolutionTEM does not provide statistically reliable data on the content of defects in the tube

walIs, it clearly shows that the o x i d i d tubes are not defect-free (Fig. M) and do not look more perfect compared to the nonoxidized DWCNT (Fig. 4b). These

wall defects, which are expected to include oxygen-terminsrted carbons, should provide highly reactive sites

an these tubes. This may be useful for cornpastes and

biomedical applications, when surface interactions with

the environment are important. However, these defects

did not cause a double.-resonance effect and did not produce a D band in Raman spectra (Fig. 2b). Acid treatment for removing the catalyst particles after the

oxidation (Figs. 4e and fl leads to a very pure and clean

sample. TEM studies of p*

samples showed neither

catalyst particles nor amorphous carbon, only DWCNT

ready for use. If any catalyst remained, its content was

well below the sensitivity limit of XRD and EDS tecbniques (less than one weight percent). The tubes formed

rings and their mean diameter was in agreement with the

experimental results and the model published by Marttl

et al. [22,23]. Rings have only been observed in oxidized

samples. The sonication provides the activation energy

far ring formatiatt. We had oxidized our DWCNTs at

high temperature in air and then sonicated them for a

short time, compared to many hours in MarteI's work,

to prepare TEM samples.

While the weight loss after heating to 600 'C was significant, further heating experiments in air have shown

that complete removal of disordered oarbon leading to

the disappearance of the D band can be achieved by

long-term isothermal treatment at temperatures Mow

400 OC and is accompanied by a much smaller weight

loss {to be published elsewhere).

h situ Raman spectruscopy analysis of the oxidation

of DWCNT showed a complete disappearance of the D

band in the Raman spactra recorded with 514 nm laser

excitation. This suggests that the D band of DWCNT

is not an intrinsic feature of these tubes; the D band

originates f r ~ m

amorphous carbon present in the sample

and not from defects h the tube walls. The described

oxidation proms provides a method for producing

nmotube samples with a very low DIG ratio (~0.015

for 780 nm excitation). The decrease or disappearance

of the D band has not been observed in MWCNT,

where defects in tube walls generate a much stronger

D band signal compared to DWCNT.

Acknowledgements

The authors are thankful to Kris Behler, Drexel University, for helpfuI comments on the Letter. This work

was supported in part by Arkema, France (MWNTs).

191 E. Borowiak-Men, T,Pichler, X. Liu, M. Knupfer, A. Gra, 0.

Sost, W.Pompe, R.J. Ulenczuk, J. Fi,Chem. Phys. Lett. 363

(2aoZ)567.

[l01 J.D. Saxby, S.P. Cbatfmld, A.J. Pdmisano, A.M. V d o , M.A.

Wilson, L.S.K*Pang, J. Pbys. Chem. 96 (1992) 17.

[Il] E. m

e

, k Bemad, H.=d,

B. Michel, H.Biebuyck,

Science 276 (1997) 779.

[I4 R.R. Bma. E. Flahaut, C. b u r n t . A. Peignty, S. AIoni, P.

Pwh,W.S. B-.

New 1. Phys. 5 (2003) 131.

[I31A.M.Rao,E. Richtw, S. Ihndow, B.Chase, P.C. Eldund,K.A.

Willhs, S. Faug, K.R. Subbaswamy, M. Menon, A. h,

R.E. Smltlley. G. DmseIhaw, M.S. Dremlhaus, Science 275

(1997) 187.

I11 E. Flahaut, A.P e i e y , C. Lamat, A. Rousset, J. Mater. Chem.

l0 (2000) 249.

p] E. Plahaut, R. Bma, A. Peigney, C. Laurent, Chem. Commun.

12 (2003) 1442.

PIL.J.G,ZL. R~o,z.P.z~ou,D.s.T~~~,Y.Q.

Y~P,Y.X.

D.F. Liu, HJ.Yuan, W.Y. Plou, G. Wang, W.Liu, S.S. Xie,

Chm. Phys, Lett. 359 (2002) 63.

141 J.L. Hutchison, N.A. K~iselev,HP.Krinichnaya.A.V. Krestinin,

R.O. Loutfy, A.P. Morawh, V.E. M d y a n , E.D.Obraztsova,

J. Sloan, S.V. Terekhov, D.N.Zakharov, Carbon 39 (2001) 761.

IS] S. Bmdow, T. Himoh, T. Y u m m , K. Hirahara, H.Shinoha,

S. I i j i i a , (3hem. Phys. Lett. 3M (2004)320.

161 S. Gajewski, H.E. Mmeek, U. Knoll, D. Neubert, I. Dorfel, R.

Mach, B. Strausq J.F. Friedrich, Diam. Relat. Mater. 12 (2003)

816.

W.Z. Li, J.G. Wen, M. Sennctt, Z.F.Ren. Chem. Phys. Lett. 368

(2003) 299.

p] S.Bandow, M.Takizawa, K.Hidam, M,Yudmaka, S. Iijima,

Chem.Phys. Lett. 337 (2001) 48.

m

[l41 H.Kuzmany, W. Plank M.HuIman, C. Kmmbzrger, A. Gruneis,

T.Pichler, H.Peterlik, M. Kataura, Y. Achiba, Eur. P h y ~J. B 22

(2001) 307.

[15] A. Jorio, A.G. Souza Filho, G. Dreadhaus, M.S. DraseIhaus,

A.K. Swan, M.S. Unlu, B.B. Goldberg, M.A. Pimenta, J.H.

Haher, CM.Lieber, R.Saito, Pbys. Rev. B 65 (2002) 155412.

[ I q C. Thomm, C. Reich, Phys. Rev. Lett. 85 (2000) 5214.

[ I 7 H.Kataura, Y.Kumuawa, Y.Maniwa, 1. Urnem, S. Suzuki,Y.

Ohtsuh, Y. Achiba, Synthetic Met. I03 (1949) 2555.

[Id S.D.M. Brown, A. Jorio, P. Corio, M.S. D d m , G.

h d h a u s , R. Saita, K. Kneipp, Phys. Rev. B 63 (2001)155414.

[19]S.H.Bokova, HD.Obraztsova, A.V. Osanchy, H.Ku~nany,U.

DeW-WegWcowska, S. Roth, m S. h r i , Y. Gogotsi V.L.

h e & m (Eds.), Nomoengimred Nanofibrous Materials, IUuW, 2 W ,p. 131.

[20] L.J. Ci, Z.P. Zhou. L. Song, X.Q. Yan. D.F. fiu, H.J. Yuan, Y.

Gao, J.X. W a g , L.F.Liu, W.Y. Zhou. G.Wan& S.$. Xie, Appl.

Phys. Lett. 82 (2003) 3098.

[21]H.Qhtsuka, T.Tabata, 0.Okada, L.M.F.Sabatino, G.Bcllussi,

CataL Lett. 44 (1997) 265.

[22] R. M w l , H.R. Shea, P. Avowis, J. Phys. Chem. B 103 (1999)

7551.

1231 R. Martel. H.R.Shm, P.Avnuris, Nature 398 (1999) 299.

© Copyright 2026