PDF (19.38 MB)

Home Search Collections Journals About Contact us My IOPscience Turbulence within variable-size wind turbine arrays This content has been downloaded from IOPscience. Please scroll down to see the full text. 2014 J. Phys.: Conf. Ser. 555 012098 (http://iopscience.iop.org/1742-6596/555/1/012098) View the table of contents for this issue, or go to the journal homepage for more Download details: IP Address: 136.243.24.42 This content was downloaded on 06/02/2015 at 15:47 Please note that terms and conditions apply. The Science of Making Torque from Wind 2012 Journal of Physics: Conference Series 555 (2014) 012098 IOP Publishing doi:10.1088/1742-6596/555/1/012098 Turbulence within variable-size wind turbine arrays L P Chamorro, R E A Arndt and F Sotiropoulos St. Anthony Falls Laboratory, College of Science and Engineering, University of Minnesota E-mail: [email protected] Abstract. A wind tunnel experiment was performed to study turbulence processes within a model wind turbine array of 3 by 8 model wind turbines of alternating sizes placed aligned with the mean flow. The model wind farm was placed in a boundary layer developed over both smooth and rough surfaces under neutrally stratified conditions. Turbulence statistics, TKE budget terms, and the spectral structure of the turbulence generated within and above the wind farm reveal relevant information about the processes modulating the turbulent energy transfer from the boundary layer to the turbines. The results of the experiment suggest that heterogeneity in turbine size within a wind farm introduce complex flow interactions not seen in a homogeneous farm, and may have positive effects on turbulent loading on the turbines and turbulent exchange with the atmosphere. In general, large scale motions are heavily dampened behind the first row of turbines but a portion of such structures are generated far inside the wind farm, and the scale of the most energetic eddy motions was relatively consistent at different elevations. Overall, the experiment revealed the possibility that heterogeneity of wind turbine size within wind farms have the potential to change the overall potential to harvest energy from the wind, and alter the economics of a project. 1. Introduction Wind farm optimization is a multidisciplinary and complex problem where turbulence plays a key role. Several variables are involved in this problem. Among them are the turbine siting, which include the inter-turbine separation and spatial arrangement (e.g., aligned [1], staggered [2], or other), wind resource, local topography, turbine size, turbulence levels, distance to the grid, and access. Research efforts are underway to reduce the total cost of energy (COE) in wind farms [e.g., 3]. Several approaches, including genetic [4, 5, 6] and evolutionary [e.g., 7, 8] algorithms have been used to address this (optimization) problem. In this investigation we focus on two fundamental aspects of the problem: a) the dynamic involved when the wind farm has turbines of various sizes, and b) the effect of surface roughness. The dynamics involved in a wind farm with variable sized wind turbines cannot be inferred directly from our understanding of the case with homogeneous wind turbines due to the fact that momentum available around each turbine within a wind farm and the fatigue loads on those turbines are sensitive to the wind farm configuration. Understanding the mechanisms that modulate the turbulent energy fluxes from the atmospheric boundary layer to wind turbine arrays is a necessary condition to tackle the problem of wind farm optimization by improving the common parameterizations used in the various models (such as wake distribution). For that reason, our study attempts to contribute toward a fundamental understanding of Content from this work may be used under the terms of the Creative Commons Attribution 3.0 licence. Any further distribution of this work must maintain attribution to the author(s) and the title of the work, journal citation and DOI. Published under licence by IOP Publishing Ltd 1 The Science of Making Torque from Wind 2012 Journal of Physics: Conference Series 555 (2014) 012098 IOP Publishing doi:10.1088/1742-6596/555/1/012098 the dynamic processes occurring in wind farms with variable rotor and hub heights, which can be used as potential parameters to consider in the context of wind farm optimization. 2. Experimental set-up Two sizes of miniature wind turbines, with rotor diameters of 0.128 m and 0.178 m, were placed in the thermally stratified boundary-layer wind tunnel at the University of Minnesota’s Saint Anthony Falls Laboratory. The model wind farm was placed in a boundary layer developed over both a smooth and a rough surface. Two wind farm configurations, consisting of 3 rows in the spanwise direction by 8 rows in the streamwise direction, were analyzed to better address the problem of optimization. All the experiments were performed under the Reynolds independence regime [9] and the turbines operated at constant tip speed ratio λ of 4.4 and 4.9 for the small and large models. A turbulent boundary layer was developed upstream of the test section with a 40 mm picket fence (serving as a tripping mechanism) located at the exit of the wind-tunnel contraction. Adjustments in the wind tunnel ceiling allowed it to grow in a zero pressure gradient. The resulting boundary layer had a well-developed surface layer with constant shear stress and a logarithmic velocity profile for the neutral stratification regime. The experiments were conducted in a free-stream velocity of approximately 13.5 ms-1, with a turbulent boundary layer height of δ ≈ 0.55 m in both the rough and smooth cases. In both cases, the zero pressure gradient boundary layer had a Reynolds number, based on the boundary layer height (δ), of Reδ = U∞δ/ν=4.94x105. By fitting a logarithmic velocity profile to the measured average velocity in the surface layer, a friction velocity of u* = 0.66 ms-1 and an aerodynamic surface roughness length of z0 = 0.25 mm were found for the rough case. In the smooth case, a friction velocity of u* = 0.54 ms-1 was found, along with an aerodynamic surface roughness length of z0 = 0.002 mm. A cross-wire anemometer was used to obtain high resolution, simultaneous measurements of both streamwise and vertical velocity components. The probe is made of 5.0 µm tungsten wires which are connected to an A.A. Lab Systems AN-1003 10-channel CTA/CCA system. In order to avoid bias errors due to thermal drift in the voltage signal, temperature fluctuations were kept within ±0.2°C. The voltage signatures were sampled from the sensor at a rate of 10kHz for a measurement period of 90s. Calibration of the cross-wire anemometer was performed at the beginning of each experimental run, with a post-experiment calibration carried out to confirm the validity of the calibration throughout the experiment. The anemometer was calibrated in a customized calibration unit with a Pitot-static probe, with the calibration performed with seven sensor inclination angles and eight flow velocities at each position. The rough surface was made with chains of 5mm height [10]. In both the smooth and rough cases, the rows of turbines alternated between large and small, with the leading row consisting of the larger sized turbines (dTL = 0.178 m). The distance between turbines was set to 8 rotor diameters (of the small turbines dTS = 0.128 m) in the streamwise direction by 3 rotor diameters in the spanwise direction. The bottom tip of the small turbines was set to a height of 0.62 times the turbine radius, and 0.65 in the case of the large turbine, which is similar to that found in large-scale turbines (≥2 MW). Measurements consisted of vertical profiles in the center of the wind-turbine array (x-z plane) at incremental steps of one rotor diameter (with respect to the small turbine size) through the wind farm, from two to seven rotor diameter behind each turbine. Each vertical profile included 39 elevations ranging from z = 10mm to z = 600mm. Between z=10 to 300 mm, Δz = 10mm, between z = 320 to 400 mm, Δz = 20mm, and between z=450 to 600 mm, Δz = 50 mm. Figure 1 shows a photograph of the set-up with rough surface and the incoming flow properties for the smooth case. 2 The Science of Making Torque from Wind 2012 Journal of Physics: Conference Series 555 (2014) 012098 IOP Publishing doi:10.1088/1742-6596/555/1/012098 Figure 1. Photograph of the variable size wind farm with the rough surface (left). Incoming properties in the central plane of the heterogeneous wind farm with a L refers to the incoming velocity at the hub of the large rough surface scenario. U hub turbine 3. Turbulent flow characteristics in a heterogeneous wind farm The normalized mean velocity distribution, U/Uhub, for the smooth surface scenario is shown in the streamwise-vertical (x-z) plane spanning the entire length of the wind farm in Figure 3. In most cases, a plot from only the smooth or only the rough scenario is provided, except for cases when the difference between the two scenarios is clearly evident and of relevance. While the mean velocity in the area above the turbines is slow to adjust, the velocity distribution behind each size of turbine, within the area below the tip height of the rotor, appears to reach a consistent profile within the second row of both the small and large turbines. This differs from wind farms of homogeneous size, where the adjusted velocity profile is typically reached later, approximately within the 3rd to 5th row of turbines [1]. Significant deviation from homogeneous wind farm turbulence distribution can be seen in the heterogeneous case, shown in Figure 4 for the rough surface scenario. Specifically, the significant turbulent wake from the top tip of the larger turbine is mostly avoided by the smaller turbine, leaving the majority of the small turbine rotor in a relatively low turbulence zone. In addition, the superposition of the wakes from upstream large and small turbines creates a more uniform turbulence distribution over the height of the large turbine rotor than in homogeneous wind farm cases [1,2]. This could work to prevent fatigue on the large turbines, as turbulent loading on the blades has a less asymmetric characteristic. Figure 4 shows a reduction in near-surface turbulence levels within the farm from the approaching boundary layer, which will be analysed and discussed at a later point from detailed inspection of eddy frequency spectra structures in the flow. Figure 3. Non-dimensional mean velocity distribution in the central plane of the heterogeneous wind farm. Smooth surface scenario. Black dots represent measurement points. 3 The Science of Making Torque from Wind 2012 Journal of Physics: Conference Series 555 (2014) 012098 IOP Publishing doi:10.1088/1742-6596/555/1/012098 Figure 4. Turbulence intensity distribution in the central plane of the heterogeneous wind farm. Rough surface scenario. Turbulent kinetic energy production is displayed along with dissipation for the smooth scenario in Figure 5. These values have been non-dimensionalized with the friction velocity, u*, and the rotor diameter of the large turbine. The values for production and dissipation are of the same order. The highest levels of dissipation are seen at hub height behind the turbines. These values are, however, non-symmetrical, with the areas of maximum dissipation seen slightly above the hub height. The maximum levels of turbulence produced from each turbine, regardless of size, are seen at the top tip of the rotor. The flow creates a negligible amount of production below the hub height and at the bottom tip of the rotor. However, the production profiles of the two sizes of turbine are structurally different. As shown in Figure 5, the turbulence production structures from the larger turbines extend farther downstream than those of the smaller turbines. This effect remains even when both the downstream distance and the production and dissipation values are normalized with the respective rotor diameters (see more details in [11]). Figure 5. Turbulent kinetic energy production (top) and dissipation (bottom) distributions in the central plane of the heterogeneous wind farm. Smooth surface scenario. The velocity measurements were used to perform a spectral analysis on the flow in order to analyse eddy frequency and glean information on the tip vortices stability. Figure 6 shows the power spectra at the top tip height, two rotor diameters (with respect to the smaller turbine) downstream of the first row 4 The Science of Making Torque from Wind 2012 Journal of Physics: Conference Series 555 (2014) 012098 IOP Publishing doi:10.1088/1742-6596/555/1/012098 of large and small turbines for both the smooth and rough scenarios. As seen from comparison of the subfigures, the addition of turbulence and surface roughness negatively impact the stability of the tip vortices. The rough surface provides a dampening of the spike showing tip vortex frequency for both the small and large turbines. The turbulence produced by the larger turbines makes the vortices generated by the small turbines negligible at 2 rotor diameters downstream. Additionally, the rough surface causes the tip vortices from the small turbine to be completely absent. The large turbine presents a strong tip vortex signature in the power spectra at approximately the same location as the small turbines. Like the small turbine spectra, this tip vortex spike is dampened with the addition of surface roughness. Figure 6. Spectra of the vertical velocity component two rotor diameters behind the large turbine of the 1st row at the top tip height for the rough (top left) and smooth (top right) surface cases. Similar spectra for the small turbine of the 1st row for the rough (bottom left) and smooth (bottom right) surface scenarios. While Figure 6 shows the spectra specifically at the top tip of the turbines, Figure 7 provides the differential power spectra along the entire height of the measurements made throughout the farm at certain locations downstream. This examines the flow features generated by the turbines in the central measurement plane. These plots are determined by subtracting the incoming power spectrum from the local power spectrum at each vertical measurement point at a given downstream point. Figure 7 provides the spectral contribution of the turbines along various profiles far inside the wind farm. The spectral contributions are determined by subtracting the incoming pre-multiplied spectrum from the local one at each vertical measurement point (pre-multiplied spectral difference). It shows that large scale motions are massively dampened at low heights behind the first large turbine. While these large scale motions are significantly dampened after the first large turbine, the plots suggest that the surface roughness far inside the farm recover these large eddy motions, though the recovery is not complete in the range analysed. At all points within the farm, the distribution of the motions generated by the turbines are qualitatively similar, with the most energetic flow features generated located L around the top tip of the large turbines, with sizes on the order of f × d TL / U hub ≈ 0.2. Although the 5 The Science of Making Torque from Wind 2012 Journal of Physics: Conference Series 555 (2014) 012098 IOP Publishing doi:10.1088/1742-6596/555/1/012098 total generated motions are similar farther downstream, they are also more energetic than upstream motions, as the generation of eddies accumulates. Figure 7. Pre-multiplied spectra of the streamwise velocity component in the central plane of the heterogeneous wind farm, six rotor diameters behind the 3rd row of the small (top left) and large (top right) turbines, and six rotor diameters behind the 1st row of the small (bottom left) and large (bottom right) turbines. Rough surface scenario. When analysing the internal boundary layer developed above the wind farm [1], it is seen that the motions generated are roughly the same as the flow features generated within the wind farm, with the L most energetic motions on the order of f × d TL / U hub ≈ 0.2 As evidenced from the downstream L L = 1.75 versus the z / z tip = 1.25 case, the development of these flow shifted flow features in the z / z tip features at higher elevations happens later on in the farm, consistent with the development of the secondary boundary layer above the wind farm. L =1.25 reveals that the large turbines dampen the The pre-multiplied spectral difference at z / z tip dominant flow motions that the turbines create above the farm. The accumulated generation of motions is higher downstream of the small turbines (denoted by thin dashed lines) than downstream of the large turbines (denoted by thick dashed lines). Therefore, the addition of smaller turbines may provide an advantage over a homogeneous wind farm setup, as they may enhance turbulent exchange between the farm and the flow above it. 6 The Science of Making Torque from Wind 2012 Journal of Physics: Conference Series 555 (2014) 012098 IOP Publishing doi:10.1088/1742-6596/555/1/012098 Figure 8. Pre-multiplied spectra of the streamwise velocity component in the central plane of the heterogeneous wind farm, at a height of approximately 1.25 (bottom) and 1.75 (top) times top tip height of the large turbine. Thick dashed lines denote locations of large turbines; thin dashed lines denote locations of small turbines. Smooth surface scenario. The effect of surface roughness on mean velocity deficit and turbulence intensity deficit in nonnegligible, as seen in Figure 9, showing these profiles six rotor diameters behind the third row of small turbines. Within the swept area of the turbine rotor (between the dotted lines), the rough surface lessens the velocity deficit as compared to a smooth surface due to enhanced mixing close to the ground induced by the higher surface roughness. However, deep within the farm, the generation of turbulence intensity is higher in the smooth case than in the rough case, where turbulence intensity is reduced below the hub of the turbine. This is due to the fact that the rough case has a higher dampening of large scale motions at low elevations, which leads to a net reduction in turbulence intensity below the hub, as the increased small scale motions do not compensate for the decreased large scale motions. 7 The Science of Making Torque from Wind 2012 Journal of Physics: Conference Series 555 (2014) 012098 IOP Publishing doi:10.1088/1742-6596/555/1/012098 Figure 9. Change in streamwise velocity component (left) and turbulence intensity (right) in the central plane of the heterogeneous wind farm, six rotor diameters behind the 3rd row of the small turbines. 4. Summary Wind tunnel experiments were performed with 8 alternating rows of 3 small and large turbines in order to analyse the flow characteristics in and above a model wind farm within a boundary layer flow. The turbines were placed 8 small rotor diameters apart in the streamwise direction, and 3 small rotor diameters apart in the spanwise direction. Crosswire anemometry was used to measure average velocity, turbulence intensity, kinematic shear stress, and production and dissipation of turbulent kinetic energy. The two setups were characterized by the surface they were placed on, with a smooth floor, and a surface that was given roughness with chains lay on the ground. Overall results from this study suggest that an alternation between large and small turbines may have positive effects on the turbulent loading on both sizes of turbine, and that the complex interactions between the two sizes of turbine may increase turbulent exchange between the wind farm and the atmosphere above. As compared to a homogeneously sized wind farm, the addition of a different size in between rows of turbines may cause the velocity profiles within the farm to become uniform earlier on, causing more consistent energy output from downstream turbines. The superposition of wakes from different sizes of turbine creates different flow conditions than would be expected in similar homogeneous farms. Turbulent kinetic energy production is more prevalent from the tip of larger turbines, and extends farther downstream; the turbulence profiles hitting both sizes of turbine are different from those hitting turbines in a homogeneous farm, and the different sizes of turbine are responsible for destruction and creation of eddy motions across a larger range of scales. These additional interactions reveal the possibility that heterogeneity of wind turbine size within wind farms have the potential to change the overall potential to harvest energy from the wind, and alter the economics of a project. If there are improvements to be made with heterogeneity, then there are additional aspects within this parameter that can be analysed and optimized, including heterogeneous 8 The Science of Making Torque from Wind 2012 Journal of Physics: Conference Series 555 (2014) 012098 IOP Publishing doi:10.1088/1742-6596/555/1/012098 streamwise and spanwise spacing between turbines of different size, optimal differences in size, and the appropriate staggering of spanwise rows. Acknowledgments Funding was provided by Department of Energy DOE (DE-EE0002980) and Xcel Energy through the Renewable Development Fund (grant RD3-42). 5. References [1] Chamorro L P and Porte-Agel F 2011 Turbulent flow inside and above a wind farm: A windtunnel study. Energies. 4, 1916-1936. [2] Chamorro L P, Arndt R E A and Sotiropoulos F 2011 Turbulence properties within a staggered wind farm. An experimental study. Boundary-Layer Meteorol. 141, 349-367. [3] Chowdhury S Zhang J, Messac A and Castillo L 2012 Unrestricted wind farm layout optimization (UWFLO): Investigating key factors influencing the maximum power generation. Renew Energy. 38 (1), 16–30. [4] Mosetti G, Poloni C and Diviacco B 1994 Optimization of wind turbine positioning in large wind farms by means of a genetic algorithm. J Wind Eng. Ind. Aerodyn. 54 (1), 105–116. [5] Grady A, Hussaini M Y and Abdullah M M 2005 Placement of wind turbines using genetic algorithms. Renew Energy. 30 (2), 259–270. [6] Sisbot S, Turgut O, Tunc M and Camdali U 2009 Optimal positioning of wind turbines on gkeada using multi-objective genetic algorithm. Wind Energy. 13 (4), 297–306. [7] Kusiak A and Zheng H 2010 Optimization of wind turbine energy and power factor with an evolutionary computation algorithm. Renew Energy. 35 (3), 1324–1332. [8] Gonzleza J S, Rodriguezb A G G, Morac J C, Santos J R and Payan M B 2010 Optimization of wind farm turbines layout using an evolutive algorithm. Renew Energy. 35 (8), 1671–1681. [9] Chamorro L P, Arndt R E A and Sotiropoulos F 2011 Reynolds number dependence of turbulence statistics in the wake of wind turbines. Wind Energy. 15, 733-742. [10] Chamorro L P and Porte-Agel F 2009 Wind-Tunnel Investigation of Wind-Turbine Wakes: Boundary-Layer Turbulence Effects. Boundary-Layer Meteorol. 132, 129-149. [11] Chamorro L P, Tobin N, Arndt R E A and Sotiropoulos F 2014 Variable-sized wind turbines are a possibility for wind farm optimization. Wind Energy DOI: 10.1002/we.1646. 9

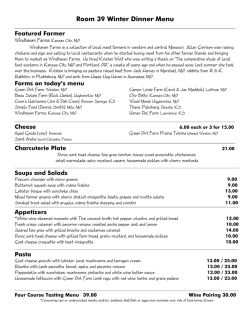

© Copyright 2026