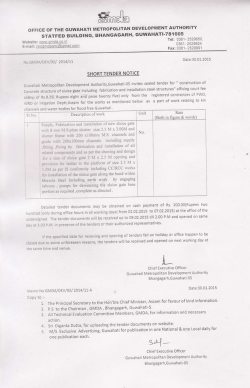

蚀蒠缮{蓌荷 瓷褺荷B荷荷{梢/蚀蒠缮{蓌147/2014 蕁鵻缮艵

¦ÉÉ®úiÉ ºÉ®úEòÉ®ú/GOVERNMENT OF INDIA

+ÆiÉÊ®úIÉ Ê´É¦ÉÉMÉ/DEPARTMENT OF SPACE

Ê´ÉGò¨É ºÉÉ®úɦÉÉ<Ç +ÆiÉÊ®úIÉ Eåòpù/VIKRAM SARABHAI SPACE CENTRE

Êiɯû´ÉxÉÆiÉ{ÉÖ®ú¨É/THIRUVANANTHAPURAM – 695 022

Ê´ÉYÉÉ{ÉxÉ ºÉÆ. ´ÉÒBºÉBºÉºÉÒ/{ÉÒ/Ê´ÉYÉÉ{ÉxÉ/147/2014 ÊnùxÉÉÆEò 30.01.2015

ADVT. NO. VSSC/P/ADVT/147/2014 DT. 30.01.2015

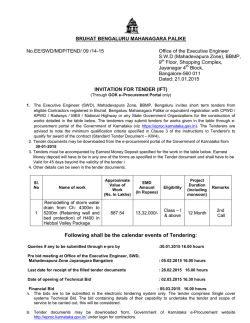

¦ÉÉ®úiÉ Eäò ®úɹ]Åõ{ÉÊiÉ Eäò ʱÉB iÉlÉÉ =xÉEòÒ +Éä®ú ºÉä ´ÉÊ®ú¹` |ÉvÉÉxÉ, GòªÉ B´ÉÆ ¦ÉÆb÷É®ú, Ê´ÉGò¨É ºÉÉ®úɦÉÉ<Ç +ÆiÉÊ®úIÉ Eåòpù

(´ÉÒBºÉBºÉºÉÒ), Êiɯû´ÉxÉÆiÉ{ÉÖ®ú¨É ¨ÉÉä½þ®ú¤ÉÆnù ÊxÉÊ´ÉnùÉBÆ +ɨÉÆÊjÉiÉ Eò®úiÉä ½éþ:

For & on behalf of the President of India, the Sr. Head Purchase & Stores, Vikram Sarabhai

Space Centre (VSSC), Thiruvananthapuram invites Sealed Tenders for the following :-

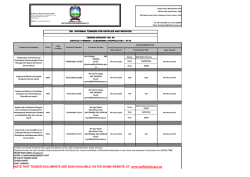

Gò¨É ºÉÆ.

ÊxÉÊ´ÉnùÉ ºÉÆ

Sl. No.

Tender No.

9301-2014-6794

[दो

दो भाग / TWO

PART]

01.

02.

03

04.

05

¨ÉÉjÉÉ

Ê´É´É®úhÉ /Description

5561-2014-6239

[दो

दो भाग / TWO

PART]

6045-2014-2191

[दो

दो भाग / TWO

PART]

6089-2013-8974

[एकल भाग /

SINGLE PART]

Qty.

वायुमंडलीय ऐरोसॉल के वेषण हे तु ूेरणामक

1 सं./No.

प से यु!"मत #लैएमा-ि(यमान ःपे+शममापी

Inductively coupled plasma – Mass spectrometer

for analysis of atmospheric aerosols

ए+स-रे /लूरोसे1स ःपे+शममापी

X-Ray Fluorescence Spectrometer

1 सं./No.

माइबो मशीिनंग से1टर

1 सं./No.

Micro machining Centre

एलओए+स पंप / 8धन पंप ूवेिशका शाखा

ूयेक 10

िनवेश संचकन

सं. / 10 Nos.

LOX Pump / Fuel Pump Inlet Branch Investment

Casting

िनवा>त संचकन मशीन

each

6089-2014-6706

[दो

दो भाग / TWO

Vacuum Casting Machine

PART]

नोट:- विनद? शन तथा वःतृत िनबंधन एवं शतC िनवदा दःतावेज़ के अनुसार

1 सं./No.

Note :- Specification and detailed terms & conditions as per Tender document

ÊxÉÊ´ÉnùÉ ¶ÉÖ±Eò / Tender Fee

ÊxÉÊ´ÉnùÉ ¡òÉì¨ÉÇ VÉÉ®úÒ Eò®úxÉä EòÒ +ÆÊiÉ¨É ÊiÉÊlÉ

Last Date for issue of Tender Forms

ÊxÉÊ´ÉnùÉ º´ÉÒEÞòÊiÉ EòÒ ÊxɪÉiÉ ÊiÉÊlÉ

Due Date for Receipt of Tender

ÊxÉÊ´ÉnùÉ JÉÉä±ÉxÉä EòÒ ÊiÉÊlÉ /

<ºÉ®úÉä ´Éä¤ÉºÉÉ<]õ

Tender Opening Date

Rs. 227/04/03/2015 16.00 ¤ÉVÉä

iÉEò/up to 16:00 Hrs.

05/03/2015 16.00 ¤ÉVÉä

iÉEò/up to 16:00 Hrs.

06/03/2015 10:00 ¤ÉVÉä/at 10:00 Hrs.

www.isro.gov.in / ´ÉÒBºÉBºÉºÉÒ ´Éä¤ÉºÉÉ<]õ www.vssc.gov.in ¨Éå ÊxÉÊ´ÉnùÉ nùºiÉÉ´ÉäWÉ ={ɱɤvÉ ½éþ *

Tender documents are available on ISRO website www.isro.gov.in / VSSC website

www.vssc.gov.in.

½þºiÉÉIÉÊ®úiÉ/Sd/´ÉÊ®ú¹` |ÉvÉÉxÉ, GòªÉ B´ÉÆ ¦ÉÆb÷É®/ Sr. Head, Purchase & Stores

Note: 1.

Full details and specifications of the items and general instructions to be

followed regarding submission of tenders are indicated in the tender documents.

2. Tender Documents can be downloaded from our websites and also be obtained

from the following address on request and submission of tender fee:

For Sl. No. 1 : Sr. Purchase & Stores Officer, Purchase Unit-II, AVN Purchase, ATF

Area, VSSC, ISRO Post, Thiruvananthapuram - 695 022, Ph : 0471-2565141.

For Sl. No. 2 : Sr. Purchase & Stores Officer, Purchase Unit-III, PRSO Purchase,

RFF Area, VSSC, ISRO Post, Thiruvananthapuram - 695 022, Ph : 0471-2563775.

For Sl. No. 3, 4 & 5 : Sr. Purchase & Stores Officer, Purchase Unit-V, MME

Purchase, RFF Area, VSSC, ISRO Post, Thiruvananthapuram - 695 022, Ph : 04712562831.

While requesting for Tender Documents please indicate on the envelope as

“Request for Tender Documents- Tender No……….. dt……………”.

3. Tender Fee (Rs. 227/-) shall be paid in the form of CROSSED DEMAND DRAFT

ONLY. Other mode of payment is not acceptable. The Demand Draft should be

in favour of : Sr. Accounts Officer, AVN Accounts, VSSC (for item under Sl.

No. 1), Accounts Officer, PRSO Accounts, VSSC (for item under Sl. No.2), &

Sr.Accounts Officer, MME Accounts, VSSC (for items under Sl. No. 3, 4 & 5)

payable at State Bank of India, Thumba Branch, Thiruvananthapuram – 695

022 [The tender fee is NON-REFUNDABLE]

Government Departments, PSUs (both Central and State), Small Scale

Industries units borne in the list of NSIC and foreign sources are exempted

from submission of tender fee. Those who are coming under the above

category should submit documentary evidence for the same.

4. While submitting your offer, the envelope shall be clearly superscripted with

Tender No. and Due Date and to be sent to the following address.

For Sl. No. 1 : Sr. Purchase & Stores Officer, Purchase Unit-II, AVN Purchase,

ATF Area, VSSC, ISRO Post, Thiruvananthapuram - 695 022, Ph : 04712565141.

For Sl. No. 2 : Sr. Purchase & Stores Officer, Purchase Unit-III, PRSO

Purchase, RFF Area, VSSC, ISRO Post, Thiruvananthapuram - 695 022, Ph :

0471-2563775.

For Sl. No. 3, 4 & 5 : Sr. Purchase & Stores Officer, Purchase Unit-V, MME

Purchase, RFF Area, VSSC, ISRO Post, Thiruvananthapuram - 695 022, Ph :

0471-2562831.

5. Quotations received after the Due Date/Time will not be considered.

6. VSSC, Thiruvananthapuram is not responsible for any postal delay/loss of documents in

transit.

7. Sr. Head, Purchase & Stores, VSSC, Thiruvananthapuram reserves the right to accept or

reject any/or all the tenders in part or full without assigning any reasons thereof.

Annexure-1

Inductively Coupled Plasma Mass spectrometer (ICP-MS) should include the following:

RF Generator: Computer controlled RF generator; Power range 500 to 1600 watts

Frequency range 27/40 MHz

Plasma Torch: Auto tunable in x-y-z directions with independent movements. Automatic

control of torch ignition, shutdown, and system warm up. Provision for auto-alignment of the

torch after routine maintenance desirable. Built-in video camera or window for remote

viewing of plasma.

Sample Introduction system: Acidic liquid sample introduction system with nebulizer,

spray chamber and peristaltic pump. Provision for high matrix introduction capability is

desirable.

Ion Extraction Interface: Two-cone (minimum) type interface

Mass Spectrometer: Quadrupole system Mass range less than or equal to 4 amu to greater

than or equal to 260 amu.

Resolution 0.4 amu or better.

Vacuum: 10-5 torr or better.

Background noise less than1cps.

Dynamic range greater than or equal to 9 orders of magnitude

Interference Management: System should incorporate Collision Cell Technology/KED or

other more efficient reaction system for interference removal in Helium mode.

Compatibility of MS with GC for the measurement of volatile organics is desirable.

Sensitivity: ~50,000 Counts/ppb at 7Li

~200,000 Counts/ppb at 89Y or 115In

~300,000 Counts/ppb at 238U

Ce++/Ce+ ratio less than or equal to 3 %

CeO/Ce ratio less than or equal to 3%

Software/ Data handling Necessary Software (Microsoft Windows based) for the operation,

data acquisition, storage, retrieval, generating reports. Networking capability desirable.

Data Acquisition System with High-end PC with ~21 inch LCD monitor and a duplex laser

colour printer (all branded items with after sales service guaranteed).

Multi element calibration standards and certified reference materials (CRMs) with

certificates.

1

Gases: All necessary gases (Ar, He, CH4, O2) with 99.999% purity. In view of the heavy

consumption of Ar gas minimum of 10 no: of Ar gas cylinders must be provided.

Necessary Gas regulators and manifold.

Exhaust system (hood, pipes, etc).

Auto sampler: greater than or equal to 30 vial capacity.

Warranty: A comprehensive 2 year warranty should be provided. Party should undertake

AMC of the equipment after the warranty period.

Power Requirements: 230 V AC/50 Hz. Suitable UPS with 1 hour backup to be supplied.

The technical comparison sheet/compliance of the quoted model must be enclosed.

Detailed specification sheet in English obtained from the manufacturer is to be enclosed.

The pre-installation requirements to be given in the quotation itself.

The system should be complete with all necessary accessories and consumables for

carrying out analysis of liquid samples.

Necessary accessories, spares and consumable for trouble free operation of the equipment for

3 years to be quoted along with system.

Application library to be supplied. List of users in India and abroad to be provided.

Instruction and operation manuals (in English) to be supplied. The system should conform to

International safety standards, designed and manufactured under a quality system.

Installation and commissioning of the equipment and training of our scientists in instrument

operation, method development, and routine maintenance must be undertaken free of cost at

the user site.

Technical bid should include model/part number of the equipment/component/ accessories

(matching with the indent specification).

Split-up cost of all necessary Foreign and Indian item is to be provided with the price bid.

2

Compliance sheet

Annexure-2 : Technical Specifications

Item Specifications

Sl.

No

1

2

3

4

5

Specifications

Compliance

Offered Specifications

(Yes/No)

Annexure

Detailed Technical Specifications for Inductively Coupled Plasma Mass spectrometer (ICP-MS)

RF Generator: Computer controlled RF

generator; Power range 500 to 1600 watts

Frequency range 27/40 MHz.

Remarks

Plasma Torch: Auto tunable in x-y-z

directions with independent movements.

Automatic control of torch ignition,

shutdown, and system warm up. Provision for

auto-alignment of the torch after routine

maintenance desirable. Built-in video camera

or window for remote viewing of plasma.

Sample Introduction system: Acidic liquid

sample introduction system with nebulizer,

spray chamber and peristaltic pump.

Provision for high matrix introduction

capability is desirable.

Ion Extraction Interface: Two-cone

(minimum) type interface

Mass Spectrometer: Quadrupole system

Mass range less than or equal to 4 amu to

greater than or equal to 260 amu.

Resolution 0.4 amu or better.

Vacuum: 10-5 torr or better.

Background noise less than1cps.

1

Compliance sheet

6

7

8

9

10

11

12

13

Dynamic range greater than or equal to 9

orders of magnitude

Interference Management: System should

incorporate Collision Cell Technology/KED

or other more efficient reaction system for

interference removal in Helium mode.

Compatibility of MS with GC for the

measurement of volatile organics is desirable.

Sensitivity: ~50,000 Counts/ppb at 7Li

~200,000 Counts/ppb at 89Y or 115In

~300,000 Counts/ppb at 238U

Ce++/Ce+ ratio less than or equal to 3 %

CeO/Ce ratio less than or equal to 3%

Software/ Data handling Necessary Software

(Microsoft Windows based) for the operation,

data acquisition, storage, retrieval, generating

reports. Networking capability desirable.

Data Acquisition System with High-end PC

with ~21 inch LCD monitor and a duplex

laser colour printer (all branded items with

after sales service guaranteed).

Multi element calibration standards and

certified reference materials (CRMs) with

certificates.

Gases: All necessary gases (Ar, He, CH4, O2)

with 99.999% purity. In view of the heavy

consumption of Ar gas minimum of 10 no: of

Ar gas cylinders must be provided.

Necessary Gas regulators and manifold.

Exhaust system (hood, pipes, etc).

2

Compliance sheet

14

15

16

17

18

19

20

21

22

Auto sampler: greater than or equal to 30

vial capacity.

Warranty: A comprehensive 2 year warranty

should be provided. Party should undertake

AMC of the equipment after the warranty

period.

Power Requirements: 230 V AC/50 Hz.

Suitable UPS with 1 hour backup to be

supplied.

The technical comparison sheet/compliance

of the quoted model must be enclosed.

Detailed specification sheet in English

obtained from the manufacturer is to be

enclosed.

The pre-installation requirements to be given

in the quotation itself.

The system should be complete with all

necessary accessories and consumables for

carrying out analysis of liquid samples.

Necessary

accessories,

spares

and

consumable for trouble free operation of the

equipment for 3 years to be quoted along with

system.

Application library to be supplied. List of

users in India and abroad to be provided.

Instruction and operation manuals (in

English) to be supplied. The system should

conform to International safety standards,

designed and manufactured under a quality

system.

3

Compliance sheet

23

24

25

Installation and commissioning of the

equipment and training of our scientists in

instrument operation, method development,

and routine maintenance must be undertaken

free of cost at the user site.

Technical bid should include model/part

number of the equipment/component/

accessories (matching with the indent

specification).

Split-up cost of all necessary Foreign and

Indian item is to be provided with the price

bid.

4

Annexure-3

Purchase Terms

1. Our normal payment term is Sight Draft / by within 30 days after receipt

and acceptance. Please confirm acceptance in your quote.

2. Specify name of Indian Agent and percentage of Agency commission, if any.

3. 10% Performance Bank Guarantee for the Warranty period shall be

furnished.

SPECIFIC TERMS AND CONDITIONS TO TENDERERS

1. Sales Tax: The facility of Inter-State purchase by Government Department

against Form-D stands withdrawn w.e.f 01.04.2007. As such, please indicate

the applicable CST/VAT.

2. Excise Duty: We are completely exempted from payment of Excise Duty in

terms of Notification No.10/97-CE Dt.01.03.97 as amended by Notification

No. 16/2007 Central Excise Dt.01.03.2007. The necessary ED Exemption

Certificate shall be provided by VSSC for availing exemption. Tenders are

requested to take note of the ED exemption available to ISRO/VSSC and

accordingly submit the offer without ED element.

3. Customs Duty: - We are completely exempted from payment of Customs

Duty

in

necessary

terms of Notification

Customs

Duty

No.12/2012-Cus dated 17.03.2012

Exemption

Certificate

shall

be

The

provided

by

VSSC for availing CD Exemption. Tenderers are requested to take note of the

CD Exemption available to ISRO/VSSC and accordingly submit the offer

without CD Element.

4. Where an agent participate in a tender;

(a) Either the Indian agent on behalf of the Principal/OEM or Principal/OEM

itself

can

bid

but

both

cannot

bid

simultaneously

for

the

same

item/product in the same tender.

(b) If an agent submits bid on behalf of the Principal/OEM, the same agent

shall not submit a bid on behalf of another principal/ OEM in the same

tender for the same item/product.

5. VSSC has a right to cancel the tender without assigning any reason etc.

6. In order to avail the benefits extended by Govt. of India to the Micro and

Small Sectors, please submit attested copy of the valid Entrepreneur

Memorandum Part II signed by the General Manager, District Industries

Centre or NSIC Registration Certificate along with your offer, if applicable.

SPECIAL CONDITIONS IN RESPECT OF TWO-PART TENDERS

I. PART I - TECHNICAL AND COMMERCIAL BID (In duplicate) in one cover.

Technical and commercial part should clearly indicate the technical details, scope of supply,

payment terms, delivery terms. [FOB/FOR/Ex-Works] delivery period, taxes and duties.

Warranty, guarantee, security deposit, performance bank guarantee, etc. under separate heads.

Please note that the price should NOT be indicated in the Technical and Commercial Offer.

Tender Fee, by way of Demand Draft should be enclosed with Technical Bid, failing which

the offer will not be considered.

Complete literature/leaflets/catalogues or brochures relevant to the offered models are to be

enclosed with the Technical and Commercial Part of the Tender.

The cover should clearly be super scribed “Technical and Commercial Bid”. The Tender Number

- due Date and Time should also be indicated on the cover.

II. PART II - PRICE BID in one cover:Price alone should be indicated (in duplicate). Wherever installation/commissioning is involved,

such charges may be indicated separately in the Price Bid.

The cover should clearly be super scribed “Price Bid”. The Tender Number - Due Date and Time

should also be indicated on the cover.

III. The “Technical and Commercial Bid” and the “Price Bid” are to be in separate sealed covers and

they should be put into a single envelope super scribed with the Tender Number, Due Date and

Time. The cover thus prepared should be sent to the following address so as to reach us on or

before the due date and time specified in the tender form.

The Senior Purchase & Stores Officer

Purchase Unit II, AVN Purchase,

ATF Area, VSSC,

Trivandrum - 695 022

IV. a) In a tender, either the Indian agent on behalf of the Principal / OEM or Principal / OEM

itself can bid but both cannot bid simultaneously for the same item / product in the

same tender.

b) If an agent submits bid on behalf of the Principal / OEM, the same agent shall not

submit a bid on behalf of another Principal / OEM in the same tender for the same item /

product.

V. Tenders may be hand delivered or sent by post or through couriers. Levels of responsibility and

reliability among couriers with respect to the delivery to VSSC are not entirely satisfactory and

tenderers shall therefore choose the couriers with particular case.

VI. The offer should be valid for a minimum period of 120 days from the due date.

VII. TENDER OPENING : The Technical and commercial Bid will be opened on the specified day and

in case any further clarification/discussions are required, such clarifications/discussions shall be

called for before opening the Price Bid.

VIII.

Late and Delayed Tenders will not be considered. Therefore, please ensure that your tender is

posted well in time to reach us before the due date and time.

IX. Tenders which are not prepared in terms of these instructions are liable to be rejected.

X. Fax / e-mail offers shall not be considered for TWO PART BIDS.

XI. All the pages of your offer should be signed / initialed by competent authority and affixed with

your Company’s Seal.

!"#$$

%&'''''''''''''

'''''''''''''''

(

( )(* +&( , (& % +&( --+( - * .(/- - ( (&*( - * 0(

+&(1(&&(/(*(*(-(&/2-&(&*(/(*((*(-(((3(*(+*&-

++4+4//5(2++*(((*(((&(%(+/&(*-2(&6(-

(&/2++*+(4(&(*(6((&/(&(&.26(+(*(*(-

7(*(&(+&.(-((*(*(*(&*+(*(+(*(*(&+(*/(

7&--//2

*.(/--((&*(-*

0(+&(1

8

(*(&&/*.(&(&(/(*((/(&&(&+.5((/((*(*(*(*(-(5

/2((*(&/*.(&((+((/(

$ 9((*(&4//.(+&*((*

/(& 3 % * % ( *(& % /((& 4(( /(5//2 /(./( * (*(* .( +/(* &/* .(

*&+/2&4&((/2((*(

: &((-*((&--+(&(3((*-(2(-+*&//+//((&

(*((& &// (&( (+(&&2 (3( +(-+(& ( .(* .2 ( - ( +&( --+(

++((**22(-&+/((&

# 176&/*.(/*-"*2&-(*(-(5-((*(

.1+(&((6(*.(6(*++*5(&*+(*((3(*(*(-;(6&

(5((&-&(&(&(+-(*((*(-(/&.(4(((4&(&-

&&.(-&(*

!(-((+(4//.(5(&((*(&--(5&/(&-(*2&+<&*.&&- *(&%

*(/(2&(

=1///./((++//((+/5(&*(*&-(&(+-+&**(/&-(

(&&/*.(-&(*/54(--(

.1/(&-+//(*-&/*.(&.(*-((-//+5(&.2((*((*(+&(&//.(

(&&./(-2/&&*5(((-*(2(&4&(((((->++(+(-

(*(4//((((&/(&&4(3(&(

+13((*5&&4(5-((&--((*&//.(*+(*2--(-*(&/*(/&

(/./((&(&/*/&.(*+(*2--(

*1 (+-+& ?> (& --((* &/* &+/2 +- &(+-+& (& - 2 &/* .(

+/(/2*+(*.2((*(((6((*((&/*/&*+((<(%2(.(

-(&(&--((***(+/5(&(++//((*&/(&4((((+(&&2/54

( 6& (& (-+( 4((( (+(&&2 &/* .( -4*(* /5 4 &/(& ;(((

&(+//(*-&(+-+&((*((&/***(&&//&+&;(((&(+-+//2

((*.2&((*((+/*&55(&+5(&&(+-+&4((&&(-(&(

@(+&(&//.(*(./5++((/4(&2(*(*(&((&(5-++(+(

-(4/(2-((*(&-(62--((**((*((&//&/2(&(

((&6(*

"(+&-2&.((&(*//&&//.(*+(*.4*&&4(//&-5(&;((

((&*--((+(.(4((&6(*4*&*-5(&6(*4*&&//(/

8 ( (*(( &/* &/2 /5 4 & (*( ( ( - & .<(& & 4(// & ( /(& +(>3

+/(+(+(-+(*/2+(&5(*.2(+(>3--+(-(+/(++((**((&(/-&

--+(-(6(*.2(+&(

88(+&((&((&(5/+(*((&++(&&-/(*((-**/62$#A-(

62--((*.2(((&6(*

8$(2-((&&55((*(-+//(*-&/*.(*+(*

8

$

:

#

(-&?>

1 ((B+&(C&//(((&*(-*&&++(&&&&&5&

.1 ( ( B+C &// ( ( (& - +2 4 4 4 4+ ( *( - (

&/2-&(&&/+(**&//.(*(((*+/*((+C&&++(&&&((&((&(&

(3(+(&**&&/(&&(3+/*(*.2(++

+1 ( ( B(&C &// ( 4 + 5((& &/2 *( ( ++ & &(+-(* (

+&(*(+/*5((+-/*+(2*&.&(6((&5&/*&++*.(

+/*(*(+&(*(

*1 ((B+&(*(C&//((++&5(*.(/--(+&(.2--+(

*/2D(*5(++(+(.(/--(+&(((&*+*&((*

(-((*(&*++++(5((*(--(-(+-&/2-&(&

/+(2(6(((-

+(&

(*(& --(5 - +(& 4// .( (-((* ;(( +( +/&( & &&(* .2 (*((

6&4(&./(+(/5&/*.(&.(*+--(&&/*./2.(&(*.2(.&(

+(<(++(-(*(5*/&(-/-2&+&

(+2(&

++(+(-(*((+&//(-(+&(*4((*&(+-(*.2

*(&4+&2(-&(+&(2*(((&(+2*(&(3+((*5

((+(-(/(-(++&(+&(&//&(+-2-(+&+//(* .2(

+&(*(&B(+2C*(+-/&*((&(+24((*&(+-(*&+

-/(&//+&(.(+-(++*(+&(&//.((/(*<((5((-

((>+&(-( &(&++(*-(&<-(+(&- .>/&( 01*01-

+/&(80.1((-*%(+(-(+*5(&&5-&+++(//

((*(/+((

1 (+&//5(((&(&&/(*&//+/2-//24(&(+-+&/**4

-(/4<&*(-+(

.1 (*-4(/(&-((++(+(-(&(&-2*(-(+&(*&+((*((2

*(-(+&((-*(*((/(**((&(&5--/2&(&*(&54<&

+&//((*2&+*(-(+&&4+&*(*(&+//(**&4(*-

8:&-(*(-++(+(((-.2(+&(4&//&(454(&(+

(&(&2((-(-/2

+1 - ( - ( +&( .(+(& (+(&&2 (/+( ((4 2 *(-(+( &(& &+

(/+((((4/&//.(*(.2(+-((-//+&&(+&(*(*(+(

-5(+-(*(-(+&5(.2(+&(&(5*4(&*(*-8:

&-(*(-++(+(((-

*1 (+-/(+-2(*(-(+&(+&(&//((5(E(+((/+((

+&-(+(4/(2-(*(-(+(&(&

(1 ( *(+& - ( +&( 4&*5 2 / ++(+( &(+ ((- .(/- - ( +&( & 4(( ( &(& &/(* .2 ( + ( *(-(+( 2

*(-(+&&*((/(*4(&*(*-8$&&4(((-(*(-(+&(6(&

((4/(/+((&//.(-/++/&(*.*5(+

-1 -/-/5((+*&/(*+/&(:010(1.((+&//(-(

+&( -& F< (( 0& (&+.(* .2 ( +&(1 - F< (* .2 (

+&( - (6/( 8A - ( /( - ( ++ /5 4 -& &(

*+(&((-+(*+/(-(++//(&(+&(F<((4//.(

((*(+42((&

51 //((/+((&(&&///&.(5((*-(*-8$&-(*(-/-&(

+&(C&&(

1 (;/((8$&5((/(&//&(&+&(4((5(((*&+//(*-.2

&(+-+&(&+&(+-+&///2&++&(&((*-8:&(-((*

:0.1,0+1&//.(&<(*-5(((*/&4&

+<54*5,&+(

(+4//.((/*(&&./(-(&(&.(5&--+(/2*(/2+<(*-&.2/

*&(4&*&D*&*(&(&-(/(*(&(+<5*<5

-+<5(&&//.(*(.2*((3(&(-(+(+&(4//2&((/2-

&&+(//&<&&.(5(3+/&(/2-(+*(+&(&//2/2-&+

&(&&(+//2(+((*5*+*++*+(4(++

! (&+(&

( + & (&&./( - .5 +/( (+( - ( & (& &(+-25 ( 5*&

*&+(*(+&5(&/*.(*(&+(*4+/(/42(+(%92(+(-&(2

(*(&(&<-(++&(4//<((&&./2-&*(/((&45

&/2-5*&4((&((.<(*&*+.&&+&(&//2-/2&+&(&&

(+//2(+((*.2(++*+(4(++

= (&(-+(

;((((6(*(&+(-+(&&/*.(&(/54(*(&+*+(&

@ ++(+(-&(&

1 ( &(& &// .( (*((* .2 ( + - &(+ &+ /+(& & 2 .( &(+-(* .2 (

+&((++C&4&<(3(&(*+&

.1 & (3(&&/2 5((* ( ++(+( - ( &(& ++(* - & &.E(+ -/ / .2 (

+&(4&(*(+&&//.(-/

+1 - ( - ( +&( // 2 - ( &(& * (( ( (-+( 6/2

(6((&&(+-(*(+&(*((22.((((E(+(*++((*+(.(-3(*

.2 ( +&( * & *(+& & (E(+ * ( +(& .( -3(* &// .( -/ .*5 (

+

*1 -(4/(2-(&(&&/(*((E(+(*++*+(4/&(@0+1.((

+&(&//.(/.(244+((++&(((<((

(3(&(-(+&(&((5((+(&&2(-+(*6/2++(*-/+(-

&( (E(+(* *(* (( ( +&( ( 5((( +&( - ( &/( &

*(4&3&-(*(-(E(+-(&(&&-(&*

" (E(+(*&(&

(E(+(*&(&4//(*(&(++C&&<*(&&./2-&+&-(*&&/

((+((*-(+4(*-8:*2&-(*(-(+(-(*+(-(E(+

(+&(&((&((&&*&+((5&+&(//+&5((E(+(*&(&

++C& **(&& ( ++C& (( &< * (3(&( (5 .(5 2./( .2 ( + +/&

8 (/(2

1 ((-*(*(-*(/(2-(&(&&/(*(+&(*(&//.(*(((*.(

(&&(+(-(++**(/(2&.(+/((*.(-((&(+-(**(&

.1 /*(+-/*(/((&(&2+&5(((-4((*(&+.(*-

&+*(/(2(+&(&//.((/(*&((

(+(-(+&5((*/6*(**5(&*.242-(/2&-#A(

4((<&.E(+3-8A-(*(/(

+&((/&(4((4+((+(++*(&<-(+(

&(&*(/((*(&-&/*(&+04(((&(3+/2+/254(+/&

((-( +&((*/2+./(&+ .(5-/1 4++(//5(

++(&(+-(+&5(0&12(*(-*(/(2

++(/(++-((-*-&*(&(*+&(D((+&(-&(&

&*(/((*(&-&/*(&+04(((&(3+/2+/254(+/&(

(-(+&((*/2+./(&+-/1(&<*+&-(+

(((-+.(5<(*(&.>+/&(01,01-+/&(8.((+&//.(/./(-

2 /&& 4+ ( +&( 2 && ++ *(* ( (>+&( - (( & 5((((+&((&+5(((&&*(4&3&-(*(-&+-/(F(

+&//.((/(*25&+(>+&(*(5&*(-/((*(*

- &+ (>+&( &// .( ( *&+( - ( +&( 4&( *(+& &// .( -/ &// .(

(+(&&2-(+&(&((+(-&+(>+&((*(-/5+&5&//

.(4(E*+((5-(+&((+(*5(&.(+-++.2(+

88 3(&-(

&&&&(++*(&+.(*((*/+&//.(&(.2(+

(+&(--/((-(+*(/((&(&((&//(&(-

2+&(4+(+&(2*&(&./(5*-(3(&-((0*&*(+&

&//.(-/1(2//4&+**/(&.(+&*(&.(E&-(*.2++&+(&-(+&(

4(E*+((+&(C&5&(+(/6*(**5(&*(+/&(8((-

8$ (+-/,+(2

;(((((+-/+(2&((&&./2-(+&(((&-(++

* +&( - + -/& +2 ( ((+ & * 4( +//(* * & 4 ( (*

&(+-(*.2(+&((+&(&//((55((((+*(52&+(-&

++(&+(((+&//.(/./(.(2**/(3(*((+&(&

/./(+4*&((+(+&//4((.((/(*25*(&++

.2(+&(

8

2(

+C&.//4//.(&&(*-2(/2-((&(&(.(((+((*&(+(**++((*.2

(+&(

8: *(-2(

//22(4//.(*(-(++((*&(&4

*2&-(*(-(+(-((/&

8# (+(2-&&*(

;(((2+/-(2(-4((/6*(*(2&5-*(&++5&

(+(+&(&//.((/(*(+(&+&.254/((&(+2

*(&(* .2 ( + - &(+2 & <( 5& ( ++ ( (( - ( &(+2 .(5

&--+(-&(+2&.((<(-(+((./+((/&(+(./(&

(+&(2.(&//.(*(*+(*-2&(*(4+2(((-(2.(+(*(

(+*(&2(++4(+&(/*&&.(&--+(+((

-// (+(./( ( + &// 2 ( +&( *(* ( (5 ./+( *(

//2-(+&(&<(&2+/4((/6*(*5&(+*(2

( ++ 4 ( +&( ( 2( - // (2& 2./( *( ( ++ ( +

+/*5(&(+2*(&&//.(4>(/*//&++/&-(+&((-//2*E*+(**

*.2(+

8! *(2

(+&//4*.(*(((*(4(*//&(&&/(*5&&++(

-(( * +/( - -5(( - 2 ( 25 *(< * &// // (& *(2 (

+&(5&//+/&4+2.(*((&(+-(&(&--5((-25(+(*.2

((5&-*(&5*(<*&//<(//&<-++*(&*5(4+2+&(

-/(-(&/2-4((+&(&5*((((&&./2-&--+(+2-//(&&(*.2

-(-/-//(-(++

8= .

(((-26(&*&(*--((+(&5*((&(+*&2+*&+(*

(+&(*(+(+4&++0(3+(&2((*(+&-4+&&(+//2

*(*-.2(&(+*&1(&(&//.((-((*(&/(.-()(*-(+&(

--+( - &( ( (& (* .2 4// .( .E(+ ( . & ((

&( ( * *(/ 4 ( 4+ ( ++ (/(& ( +&( - & *(& &

((&((&(3(&&(*(4&//2((&*&(*--((+((4*-

(.&//.(-/*.*5((&-&++

&(-&++

1 -(..(()(*-(+&(--+(

01 (((-&.(5&-((*+5&--+(.2(&5(4&(&//.(/4-/-&

&++(&&>>--+(((+((*4(-((+(&(/-((&&.

01 ( (( - & .(5 4//5 ./( + - 2 (& &// .( /4-/ ( )(* - (

+&(--+(((&&.

.1 -(..((&(*.2()(*-(+&(--+((((-&*25(5/(+5

(-&5 + (&55 .(5 ./( + - 2 (& &// .( /4-/ - ( )(* - (

+&(--+(((+((*4((-((+(&(/-((&&./+(-

(55.

.E(+ & -(&* ( . * +/ + 8""! * ( /(& ((*( * 2 &2

*-+&((--((.(5-+(&//.(*(((*/2(.+((*5&*(&

/&((.&//((4((3(*4(+&(-(+&(*(+(

(-<5*./&5(4*(((-.&//.((/+(&+&(&&.&/(

*&+( 2 *((( ;< *( ( ++ &// - (&./2 &&./( +( *5 .

+((*5&

8@ ((&**-/(&

;(( +( (& * +*& % (* +2+/&2/(* +*& ( .(( --((* .2 ( &/( (

&(&//.(*(((*(.((++((*.2(+&(/(&&&(+-+4(++(+(((-&

.(*

8" (+2-+&(C&(/&

++(&&-/(*((4//(-&(--.<5((2(-&+//(*-.2(

+&(4*&*(6(&(+2-((/&%(2*(*.2(+&(-(*((3(+

-(++

Annexure-III

SPECIAL CONDITIONS IN RESPECT OF TWO-PART TENDERS

I. PART1-TECHNICAL AND COMMERCIAL BID (in duplicate) in one cover.

Technical and Commercial Part should clearly indicate the technical details, scope of

supply, payment terms, delivery terms, [FOB/FOR/Ex-Works] delivery period, taxes and duties,

warranty, guarantee, security deposit, performance bank guarantee, etc. under separate heads.

Please not that the price should NOT be indicated in the Technical and Commercial Offer.

Complete literature/leaflets/catalogues or brochures relevant to the offered models are to be

enclosed with the Technical and Commercial Part of the Tender.

The cover should clearly be super scribed “Technical and Commercial Bid”. The Tender

Number-Due Date and Time should also be indicated on the cover.

II. PART II –PRICE BID in one cover:Price alone should be indicated (in duplicate). Wherever installation commissioning is

involved, such charges any be indicated separately in the Price Bid.

The cover should clearly be superscribed “price Bid”. The Tender Number- Due Date and Time

should also be indicated on the cover.

III. The “Technical and Commercial Bid” and the “Price Bid” are to be in separate sealed covers

and they should be put into a single envelope superscribed with the Tender Number, Due

Date and Time. The cover thus prepared should be sent to the following address so as to reach

us on or before the due date and time specified in the tender form.

Sr. Purchase Officer

Purchase Unit No.III

Vikram Sarabhai Space Centre

ISRO PO

Trivandrum –695 022

IV.Tenders any be hand delivered or sent by post or through couriers. Levels of responsibility

and reliability among couriers with respect to the delivery to VSSC are not entirely satisfactory

and tenderers shall therefore choose the couriers with particular care.

V. The offer should be valid for a minimum period of 120 days from the due date.

VI. TENDER OPENING. The Technical and Commercial Bid will be opened on the specified

day and in case any further clarifications/discussions are required, such clarifications/discussions

shall be called for before opening the Price Bid.

VII. Late and Delayed Tenders will not be considered. Therefore, please ensure that your tender

is posted well in time to reach us before the due date and time.

VIII. Tenders, which are not prepared in terms of these instructions, are liable to be rejected.

IX. Fax offers shall not be considered for TWO PART BIDS.

X. All the pages of your offer should be signed/initialed by competent authority and affixed with

your Company’s Seal

!

/

6

7

8

;

<

=

0

!

/

6

7

8

"#

$ %&'() '

*"

++++++++++++++

$ " (

, "

( "

#

-

#

% . "

/0

1

$ ( "(

"

#

2 3

"

$ 1

$ &43

(

$ 4

$ -

$ 5

(

%& ( ) !0

1

9 :

%

"

#

#

#

9

#

%

% > "

?

#

. 1

.

#

$#

$ "

'

""

(

3

4

9

@ $

A#

3 '4 1 1 ( $

A(3

(3

1

$

A#

%3

#

#

(

$

A1

3 ( #

%

/

/!

!

"

$

<

<!

</

%

@

1

4

& 5 B 1 5 2

4

9(

#

159(

C

$

%&9"&

$

( " (

$

#49

4

$

(%(

$

(

$

5 1 1

4 #

$

@

!0

-9

/!

1 /!&4

D

0*!

$

/*6

"@&"

++++++++++++++++++

++++++++++++++++++

++++++++++++++++++

#

#

5

3

(3

4

3

3

1

*

3

@

3

( B

'

""

"4

4

4

>

7

7!

7/

#

)1

%(-1'11(C8=70!!

#

)1

%(-1'11(C8=70!!

&

4 4

,*

#E-(2"1?%-5?-%+++++++++++++++++++5,++++++++++++

#E-(2"1?E

B%'?->?% 5"

5?#"->?% 1#"(?

5?1"%,+++++++++++++

#%-% ?-F,+++++++++++++++

1

#

#

#

%

'

#

((

,*

$

.#

(

41

("

#

(

$

.#

(

(

7 1

#

(

=

1

(

7 #

"(

#

#

$

$

76

!

"

"1

1 1

D $

(

#

( #

(

7(

#

(

=

(

#

4

9

(

(#

(

1

4

.

G

$ -

1

(

$ 7

$ " .

3

=

$

%

)

>.

B

B 4

7 #

.

*+

#

D07

$

4

D0$

$ 4

$

4

6

#

1

$ #

1

(

#

6

$ 1(

#

.

$ ! $

(

!0D$D$

&4 B D

*&4 B

$&4

0H

%

&4B(

$ "

!

3

$ ?!

G 6 (

!0D$D$

A

43

+*

4 &

$ (

4

4

$ 4

4 $ #

4

$ I

4

$ $

"

&4

;

/

$(&9"@&#

#-D*

$

$D/

$

$#49

D/

$

!

"

$

%

$

(D/

$

$(%

(

4

.

( (#

2

" ?

1

4

#

-

>4

4

4

@

%

G4

1

&

@ 4 &4

D1 &4 +++++++++++++$

&4

#

3

,

(I)

Annexure-I

Technical Specifications of Micro Machining Center for Advanced Ceramics and Mettalic materials

( 5 axis CNC Micro Rotary Ultrasonic Machining (RUM) center)

Type : Portal type compact 5 axis machining center with intregrated NC-swivel/tilt rotary table .

Portal type compact 5 axis machining center with intregrated NC-swivel/tilt rotary table .

This 5 axis CNC micro Machining Center should be configured as X,Y,Z and A,C or B,C capable of maching of ceramic material such as glass,borosilicate,zeoder

etc, hard metalic materials,composites in ultrasonic mode and micro milling ,drilling and grinding operations on aerospce materials including titanium and Inconel

in a single machine. This Machining Center shall be equipped to control ultrasonic parameters like vibration frequency ,amplitude etc and it should be suitable

for effective machining of brittle and hard materials. It shall be configured with high dyamics for all three linear axes (X, Y, and Z) . It shall be capable with

simultaneous linear interpolation of 5-axis X,Y,Z and A,C or B,C. It shall be equipped with state-of-the-art of CNC control system and drives and also equiped with

adaptive control , accoustic control features for effective ulisation in ultrasonic mode.This machine shall have fully integrated through coolant system with

(II)

1

1.1

1.2

1.3

1.4

1.5

2

2.1

2.2

2.3

2.4

2.5

2.6

3

3.1

3.1.1

3.1.2

3.2

3.2.1

3.2.2

3.3

3.3.1

3.3.2

3.3.3

3.3.4

3.5

4

4.1

4.2

filteration system.The machine bed shall be rigid enough for vibration isolating and damping

5 axis CNC Micro Rotary ultrasonic machining center Specifications

Construction:

Portal type/Gantry design with intregrated NC-swivel rotary table .

Highly precision drive for linear axis

Good vibration damping: Pl specify details like bed construction material and damping properties etc

Thermal stabilized/compensation

Guide ways - please specify details

Axis travels (Nominal)

X-axis

mm

200

Y-axis

mm

200

Z-axis

mm

250

C-axis

deg

Continuous

A or B axis ,For A

deg

please specify

A or B axis,For B

deg

please specify

Machine Accuracy (as per VDI DGQ 3441))

Position uncertainty (P)

Linear axis (X, Y & Z)

mm

0.007

Rotary table ( A or B and C-axis)

Arc sec

7

Positional Scatter (Ps)

Linear axis (X, Y & Z)

mm

0.004

Rotary table ( A or B and C-axis)

Arc sec

4

Geometrical Accuracy

Squareness for all linear axis

mm/mm

0.01/200

Straightness for all linear axis

mm/mm

0.01/200

Parallelism of X-axis to table

mm/mm

0.01/200

Perpendicularity of Z-axis to X &Y

mm/mm

0.01/200

Test chart for both positional and geometrical accuracies for similar

machine shall be enclosed along with quotation

NC Rotary table

Type

NC controlled swivel/tilt rotary table

T-slot

Required provide details

4.3

4.4

4.5

4.6

4.7

4.8

5

5.1

5.2

5.3

5.4

5.5

5.6

5.7

5.8

5.9

5.9(a)

5.1

5.11

5.12

6

6.1

6.2

6.3

6.4

6.5

7

7.1

7.2

7.3

7.4

7.5

7.6

7.7

Table size (Nominal)

mm

200X200

Table load

Max. speed

Drive system

Torque

Resolution

Milling/Ultasonic spindle

Spindle type

kg

rpm

10 kg(Nominal)

Pl. Specify

Pl. Specify

Pl. Specify

0.001

Speed range

Spindle power at 100% duty cycle

Spindle torque at 100% duty cycle

Beraing type

Constant power range

Spindle taper

Air blast taper cleaning

Spindle runout at nose

degree

Please specify (prefer electrospindle)

RPM

20-40000 (step-less)

kw

15(Nominal)

Nm

6(Nominal)

Pl. Specify

Pl. Specify

HSK 32

Required

micron

3

Spindle cooling type

Pl. Specify

Spindle speed-torque characteristics shall be provided along with quotation

Capability of mimimum hole size in ultrasonic mode

please specify

µm

Spindle tool clamp

Please specify

Ultrasonic generator

Power

Watt

250 watt (nominal)

Gererator frequency

KHZ

20-50KHZ (Nominal)

Please specify

Able to set automatic resonancy of any tool auto mode

µm

Pl. Specify (Quote as optional)

Automatic amplitude regulation & vibration amplitude range

Pl. Specify

details

Programmable ultrasonic parameters for vibration amplitude,frequency and

ultrasonic

power

Feed and Feedback system

Pl. Specify

Drive for linear axes

Pl. Specify

Bearings for linear drive

Pl. Specify

Drive for rotary axis

precision Roller

Guideways

Linear measuring system with glass scales

Feedback elements

Pl. Specify

Maximum feed force on X, Y, Z and A or B

Pl. specify type

NC Rotary table locking system required

Feed back control capable of monitoring the process & adjusting process

7.8

Required

parameters through adaptive control

8 Feed & Rapid traverse rates in X, Y and Z axis

8.1 Feed rate

mm/min

0 to 30,000

8.2 Rapid traverse rate

m/min

30

2

Acceleration

please specify

8.3

m/s

9 CNC system

9.1 Control

Latest Heidenhain/Siemens

9.2 Hardware

9.2.1 Resolution

0.0001

µm

X, Y, Z, A or B and C

9.2.2 Controllable axes

9.2.3

9.2.4

9.2.5

9.2.6

9.2.7

9.2.8

9.2.9

9.2.10

9.2.11

9.2.12

9.4.7

9.4.8

9.4.9

Display

NC program memory

Hard disk /solid state memory capacity

Feed override

Spindle override

Solid graphic simulation

Dust proof casing for CNC system

Machining time calculation

Tool tables, workpiece datum tables

Electronic hand wheel

Safety package for power failure,voltage control with fast

deceleration trigger

Uninterrupted power supply (UPS) for control display of last executed

program number

Data Interface

USB Ports

Ethernet

Programming

ISO programming in metric & inch

Cartesian, polar programming

Free contour programming

Parametric programming

Mathematical functions, logical operators

Coordinate transformation linear transformation, rotation in the machining

plane, scaling

Sub programs

Programming aids

Parallel programming

9.5

9.5.1

9.5.2

9.5.3

9.5.4

9.5.5

9.6

9.6.1

9.6.2

9.6.3

9.6.4

9.7

9.7.1

9.7.2

9.7.3

9.7.4

9.7.5

9.7.6

9.7.7

Cycles

Drilling

Thread milling cycles

Cycles for clearing level & inclined surfaces

Multi operation machining of pockets

Contour pocket machining cycles

Interpolation

Linear interpolation in 5 out of 5 axes

Circular interpolation in 2 out of 5axes circular interpolation

Helical interpolation

Spline interpolation

Control System Options

3D Graphics Simulation

Probe cycles

High Speed Machining Cycles

NURBS Interpolation

Dynamic approach buffer (FIFO)

Dynamic look ahead (feed forward control)

Block search with and without computation

9.2.13

9.2.14

9.3

9.3.1

9.3.2

9.4

9.4.1

9.4.2

9.4.3

9.4.4

9.4.5

9.4.6

17” TFT (Minimum) color display

GB

2

GB

pl specify

Required

Required

Required

Required

Required

Required

Required

Required

Required

Minimum 2 Nos. Required

Required

Required

Required

Required

Required

Required

Required

Required

Required

Required

Required

Required

Required

Required

Required

Required

Required

Required

optional

Required

Required

Required

optional

Required

Required

Required

9.7.8

9.7.9

9.7.9

9.8

9.8.1

9.8.2

9.8.3

9.8.4

9.8.5

9.9

9.9.1

9.9.2

9.9.3

9.9.4

10

10.1

10.2

10.3

10.4

10.5

10.6

10.7

11

11.1

11.2

11.3

11.4

11.5

11.6

Manual Data Input (MDI)

Tool retract at time of failure

Setup functions (JOG) for all axes

Compensation

Cutter radius compensation

Tool length compensation

Pitch error compensation

Quadrant error compensation

Backlash compensation

5- axis control options

RTCP

Inclined plane machining

5-axis interpolation functions (Siemens TRAORI or equivalent)

3D cutter compensation

6. Automatic Tool Changer

Type

Number of tools

Minimum tool diameter

Maximum tool diameter

Maximum tool length

Maximum tool weight

Average tool change time

Coolant system

Through Coolant supply of the spindle

External Coolant supply of the spindle

Pressure

flow rate

Coolant tank capacity

Maximum allowable particle size

Required

Required

Required

Required

Required

Required

Required

Required

Required

Required

Required

Required

Pl provide details

20 (Minimum)

mm

Pl. Specify

mm

Pl. Specify

mm

Pl. Specify

kg

Pl. Specify

s

Pl. Specify

Required

Required

bar

l/min

L

<10 µm

11.7 Coolant reprocessing plant with ICS supply pump is required

quote optional

11.8 Fully Integrated Mist coolany system pl provide details

12 Chip removal system

12.1 Type of chip conveyer

13 Machine Guarding

All moving parts/guide ways/ball screws shall be protected against dust

13.1

incursion by providing suitable covers/bellows

13.2 Machine shall be provided with adequate guarding & doors

quote optional

13.3

Control system elements shall be enclosed in a dust-proof and air

conditioned cabin. The cabin shall prevent entry of rodents.

14

14.1

14.2

14.3

15

Electrical specifications

Voltage

Frequency

Isolation Transformer & Stabilizer(Make servomax/Neel)

Environmental conditions

pl secify

pl secify

pl secify

quote optionally

415 V ±10% AC, 3 phase

50 Hz ± 2%

Quote Separately in INR

15.1 Supplier shall comply with suitability of machine operation in tropical environmental conditions (85% RH and 37°C temperature)

16

16.1

16.2

16.3

16.4

17

17.1

17.2

17.3

18

19

Machine size and weight

Floor space required

Pl. specify

Type of machine foundation

Pl. specify

Total Weight of machine

Pl. specify

Max. Weight, numbers & size of packing shall be indicated

Accessories

Touch trigger probe for workpiece measurement (Renishaw preferred)

Required

Type BLUM/Renishaw Laser tool presetting and relevant cycles

Quote as Optional

Integrated kinematic correction kit (Hardware and software)

Quote as Optional

Spares and consumables for 2 year trouble free operation may be listed and quoted separately

20

Tool holding

Standard tool package suitable for holding ultrasonic tools and milling

Quote as Optional

tools pl provide details showing type and number being supplied

Ultrasonic shrinkfit type holder

3 Nos.

Ultrasonic collet type holder

3 Nos.

HSK 32 Hydraulic holders with collets for milling

4 Nos.

Inspection and Installation

Pre-delivery inspection at manufacturer's site in presence of VSSC engineers

Work holding

Work holding for different types of advanced materials like glass,ceramics

Quote as Optional provide details

19.1 for zero point clamping( make sytem 3R/EROWA)

20.1

20.1.1

20.1.2

20.1.3

21

21.1

21.1.1

21.1.2

21.1.3

21.2

21.2.1

22

22.1

22.2

22.3

22.4

22.5

22.5.1

22.5.2

22.5.3

23

23.1

24

24.1

24.2

25

The machine shall be inspected as per VDI/DGQ 3441 standards for positional and geometrical accuracies as per standard test chart

NAS 979 cutting test for confirming machine accuracies and performance

Machining demo on component requiring 5-axis simultaneous interpolation

Installation and commissioning at VSSC site

Required

Geometry of machine should be inspected as per test charts

Training

Programming and Operation training at manufacturer's works

Maintenance and basic troubleshooting training at manufacturer's works

Programming and Operation training at VSSC

Maintenance and basic troubleshooting training at VSSC

UltrasnicTraining

Demonstatrion of ultrasonic parameters for for different ceramic materail specially for micro feature machining

Ultrasonic technolgy and its application and new development

Programming and Operation training for ultrasonic at VSSC

Documentation

Two sets of hard copy of programming, operation and maintenance manuals and a soft copy of all manuals shall be supplied along with the machine.

Delivery

Delivery shall be on FOB basis

Delivery period shall be indicated in the offer

Machine Acceptance

25.1 The machine will be accepted based on satisfactory completion of activities of section 21 and 22 & compliance of test charts

26 Warranty

26.1 Minimum of one year warranty from the date of commissioning.

26.2

27

27.1

27.2

27.3

27.4

27.5

Mandatory Annual maintenance contract for additional five years shall be quoted separately

Others

Technical leaflet and write-up of equipment must be furnished

Quotation shall be prepared and signed by the original machine manufacturer

Actual test both linear and geometrical test certificates of similar model manufactured by the manufacturer have to be sent along with the quotation

Reference of users (with contact address) where similar machine is in operation

Data sheets with complete technical information to support the specifications listed in Section 1 to 11 shall be provided.

Note:

* Duty Exemption : We are exempted from payment of Excise Duty / Customs Duty / Octroi Duty and necessary duty exemtion Certificate will be provided by us.

Please quote accordingly.

* Ours is a Govt. of India Department and we can not issue any concessional form. Hence please quote normal rate of VAT

* WARRANTY : The items shall have a warranty for a period of One year against any manufacturing defects or bad workmanship from the date of Commissioning.

Warranty certificate duly signed & stamped shall be provided after successful Commissioning at our site. You shall supply Performance Bank Guarantee for 10%

of Order value towards Warranty support. PBG should have a claim period of 6 Months.

-1Annexure II ( 2-Parts Instructions)

Ref. No. 6045-2014-00-2191-01

M/s.

Dear Sirs,

Sub:

MICRO MACHINING CENTRE FOR ADVANCED CERAMICS AND

METALLIC MATERIALS[5 AXIS CNC MICRO ROTARY ULTRASONIC

MACHINING(RUM) CENTER]

********

Vikram Sarabhai Space Centre invite Public Tender for the above item in TWO

PART. Please find the enclosed set of tender documents along with technical specification

and Commercial terms & conditions for this tender enquiry. Please send your offer in TWO

PART as follows:

PART –I:

PART-II:

SHOULD CONTAIN TECHNICAL AND COMMERCIAL ONLY

SHOULD CONTAIN

PRICE DETAILS ONLY

PROCEDURE TO BE FOLLOWED BY TENDERS

PART-I : TECHNICAL & COMMERCIAL

1. Our tender enquiry contains technical requirements and specification of

items. The detailed technical specifications of your offer should be covered in this part.

This part should not contain Price Details. This should be sent in a sealed envelope duly

super scribing the following details on the top of the envelope.

Quotation against Tender Enquiry No. 6045-2014-00-2191-01

Due on:

time :

for MICRO MACHINING CENTRE FOR ADVANCED CERAMICS AND METALLIC

MATERIALS[5 AXIS CNC MICRO ROTARY ULTRASONIC MACHINING(RUM)

CENTER]

PART-I : Technical proposal & Commercial terms

2. The commercial terms to be covered in this part are Delivery Terms,

Delivery period, Payment terms, taxes and duties (if any), Validity of the offer,

Warranty, Guarantee, Performance Guarantee, Liquidated Damages (for delayed

supply) etc.

3. You are required to confirm acceptance of all our terms and conditions. If any of our

terms is not acceptable, you may offer counter terms with adequate justification for our

consideration.

-2-

PART-II :

PRICE DETAILS

1. The price of the item should be indicated in this part with unit rate. The prices are to be

mentioned both in figures as well as in words and each page is to be signed by

your

authorized signatory.

2. This part Viz. PART-II should be sent in a separate sealed envelope super scribing as

follows on the top.

Quotation against Tender Enquiry No. 6045-2014-00-2191-01

Due on :

time :

for MICRO MACHINING CENTRE FOR ADVANCED CERAMICS AND

METALLIC MATERIALS[5 AXIS CNC MICRO ROTARY ULTRASONIC

MACHINING(RUM) CENTER]

PART-II : Price Details

All this two envelope shall be kept in another envelope duly sealed and super scribed

on the top of envelope as mentioned below.

Quotation against Tender Enquiry No. 6045-2014-00-2191-01

Due on:

time :

for MICRO MACHINING CENTRE FOR ADVANCED CERAMICS AND

METALLIC MATERIALS[5 AXIS CNC MICRO ROTARY ULTRASONIC

MACHINING(RUM) CENTER]

PART-I , PART-II

Note: - All the envelope should bear the from address of the tenderers and address to

Attn:

Sr. Purchase & Stores Officer

Purchase Unit-V, MME Purchase

RFF Area, VSSC , ISRO Post

TRIVANDRUM-695 022

Tele: 0471-256 2831/3611/3577

Fax : 0471 - 2562021

Your offer to the above mentioned system should reach us on or before the due date

and time i.e. on

Time :

Hours IST. Offers received after

IST of

will be treated as late and invalid.

Hours

Any quotation received deviating the above instruction shall be summarily rejected. Hence

please adhere to the above details and submit your quotations before due date and time.

Encl: - 1. Instruction (Commercial Terms)

2. Technical Specification and Terms and Conditions – Annexure- I

© Copyright 2026