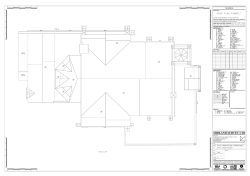

Typical Private Drainage Details

A1 CONCRETING OF DRAINS LAID NEAR FOUNDATIONS (as BS EN 752). PIPE BEDDING DETAILS INTERNAL WASTE PIPE CONNECTION PIPE DIAMETER EXTERNAL R.W.P. TO DRAIN S.V.P. TO DRAIN EXTERNAL R.W.P TO GULLY 40mm Waste pipe Soil & Vent Pipe 4D.296 Socket plug with 4D.399 boss socket adaptor When D is less than 1m, concrete fill to level of foundation bottom. D 100mm 10mm nominal single size 150mm 10mm or 14mm nominal single size 150mm - 500mm 10mm, 14mm or 20mm nominal single size OVER 500 10mm, 14mm, 20mm or 40mm single size 68mm RWP 4D.149 S/S Adaptor NB. GRANULAR MATERIAL FOR BEDDING AND SIDEFILL TO CONFORM TO BS.882 : 1983. 4D.900 Bottle gully ROCKER PIPE LENGTH PIPE DIAMETER (mm) 4D.205 Pipe coupler Note A: For Dimensions and Depths of Foundations Refer to Structural Engineers Details GRANULAR MATERIAL SIZE 68 mm RWP 4D.274 S/S Access pipe BS 8301: 1985 Code of Practise for Building Drainage 3/11.1.1 The design of Bedding for pipelines is based on the principle that the ability of a pipe to carry a load may be increased by the provision of suitable bedding. A rigid pipe has inherent strength but by providing a degree of encasement higher loads may be carried. A flexible pipe will deform under the application of loads and requires support from surrounding material, and thus from the sides of the trench, in order to avoid excessive deformation of the pipe. 4D.205 Pipe coupler 4D.561 87 Degree bend Note B: Recognition shall be taken of the manufacturer's recommendations in the application of the details shown on this drawing to proprietory products. Bend to suit To Chamber CHAMBER TYPE RE OSMA RODDING EYE When D is 1m or more, concrete fill to within D - 150mm of level of foundation bottom. x+600 max x+300 min 4D.563 Bend 33 150 150mm side fill as per pipe bedding specification Raking length of pipe Equal junction 150 MIN 6D.934 or 6D.938 Concrete Protection To Pipes Below Buildings PIPES PENETRATING WALL / FOUNDATIONS 3. 4. x+600 max x+300 min OSMADRAIN 5. Typical Branch Connection Lintel 300 BASE 6D.936 100mm bed as per pipe bedding specification GATIC SLOTDRAIN 100mm UNISLOT S12305 SECTION AND PLAN DETAILS ASPHALT INSTALLATION C250 LOADING ONLY Manhole cover & frame bedded on mortar; BS EN 124 load class and min opening to suit proposed installation location and adopting organisation Precast concrete cover slab to BS 5911-3 and BS EN 1917. Bedded on mortar or a proprietary bitumen or resin mastic sealant mortar pointing to internal face 500mm 2-4 courses of Class B engineering clay brick to BS 6073. Alternatively precast concrete masonry brick and block units to BS 6073 or precast concrete seating rings to BS EN 1917 and BS 5911-3 Concrete to be poured up to the level of the Wearing Course Cast in-situ concrete strip footing. Min 300 x 150mm thick ST4 standardised prescribed concrete to BS EN 206-1 and BS EN 8500-2 Second pour to be done when the first pour has sufficiently cured minimum grade C32/40 Concrete (Elkington Gatic recommends using 20mm aggregate) Asphalt Wearing Course 10 Asphalt Base Course Polystorm Access shaft 1.2m - 3.0m DEEP Min 300mm granular material surround to Polypipe Access shaft Polystorm Access turret unit Single Polystorm unit (per layer) omitted from Polystorm structure construction 450mm Polystorm structure 100 200 100 200 BEDDING CLASS S Haunch Slotdrain at feet to correct level Granular bed and surround 3000 1000mm (500mm wide) 54 Concrete Bed and Surround mix GEN3 min cover 150mm Shallow Square Unperforated Bucket Asphalt to be rolled in line with the channel Access point outlet box silt box 36 Exceeding 1200 Gulley Pot 225mm Nominal Diameter PLAN DETAIL Polystorm Access base unit 18 450 - 1200 Gully Grating Feet at ends only First concrete pour to fix the channel to the bottom of the trench minimum grade C32/40 Concrete (Elkington Gatic recommends using 20mm aggregate) to 20mm below the invert of the channel to allow the concrete to flow underneath Thickness of Compressible filler (mm) Less than 450 Asphalt to be rolled in line with the channel (see plan view) Trench 10 150mm side fill with no particle size larger than 40mm TABLE A - Joint filler thicknesses Nominal diameter of pipe (mm) 20 100 211 CHANNEL INVERT DEPTH To allow for possible differential movements a flexible joint must be incorporated in each section of the pipeline within 150mm of where it enters a building or connection with an inspection chamber, manhole wall or other structure. ALL DIMENSION ARE IN MILLIMETRES. This drawing is to be read in conjunction with Appendix 5/1 Dimension X is the external diameter of the pipe The minimum or maximum width of the trench applies on and below a line 300mm above the outside top of the pipe. Above the 300mm line the trench backfill material shall be as described in Clause 505 SHW The concrete bed or surround may extend to the outsides of the trench or be of minimum width. Class 8 material is to be used to fill any voids so formed For Type Z trench the concrete cover may be formed to a radius batter or horizontal surface. Min cover of concrete shall be 150. 120 25mm Class 1 mortar haunching to MH cover and frame 50 6. Polystorm Access Typical Installation Detail 100mm bed as per pipe bedding specification 1. 2. BEDDING CLASS Z X 150 max NOTES 100mm min Covering layer X/6 100 min 600 max Class 8 material to S.H.W. Clause 503.3(iv) X D - 150 4D.163 Bend 150 mm Sidefill 150 MIN 1250 Material to S.H.W. Clause 503.3(ii) 150 COVER & FRAME Up to 1.2m deep use 6D.935 (450mm dia) Over 1.2m deep use 6D.939 (350mm dia) Branch Connection GEN3 concrete surround material 825 AND OVER Granular material to S.H.W. Clause 503.3(i) X/4 100 min 100 Compressible material 1000 Key D Main sewer 600 675 - 750 4D.360 Rodding Eye CHAMBER TYPE NEIC OSMA NON ENTRY INSPECTION CHAMBER Excavated backfill 150 - 600 Pre-cast concrete or brick base 4D.561 87 1/2 Degree bend 4D.581 87 Degree long radius bend ROCKER PIPE LENGTH (mm) DO NOT ROLL OVER THE CHANNEL TYPICAL YARD GULLEY DETAIL NOTE: The responsibility to provide the foundation design should be that of the project engineer. the foundation should be strong enough to take the anticipated loads from the largest vehicles that will traffic the channel. STAGE D OSMA SILT TRAP SLB600 Top of Concrete Fillet/Mounting block ORIFICE CONTROL CHAMBER NOT TO SCALE Outlet pipe Geosynthetic encapsulating Polystorm Units 300mm Square x 10mm thick Stainless Steel `Orifice Plate' Min 100 Orifice Plate bolted to Concrete Fillet mounting block with 4 NO. M12 Stainless Steel Resin/Chemical anchor bolts, min. embedment 75mm. Neoprene Gasket/Seal to be provided between plate and Concrete Ridgidrain 100mm/110mm EN1401-1 Flange Adaptor (Product Code: PSMFA110) DETAIL A ORIFICE PLATE pipe pipe in from system Orifice Plate Orifice Plate Level Invert Orifice Concrete Fillet/Mounting block at low level to provide flat surface to fix Orifice Plate. Fillet approximately 150mm thick at its widest point Pipe bed & surround POLYSTORM TYPICAL INSTALLATION DETAIL Typical Private Drainage Construction Details outlet pipe to surface water drain Polystorm Units Either: Coarse sand OR Class 6H selected granular material (100% passing 5mm sieve) Highweek School Newton Abbott Devon Refter to detail A TYPICAL SECTION NTS NPS South West TYPICAL PLAN 14-1-0360-RL-SD-C-200 P1

© Copyright 2026