MS80W II MS100 II

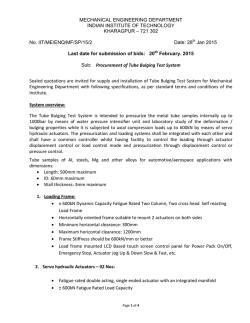

HIGH-SPEED, LOW-PROFILE DESIGN MS80W II MS100 II SPOT WELDING KEY BENEFITS Reduced life cycle cost and increased cable life with proven integrated power and utility cable harness Designed to take advantage of lighter weight Mid-Frequency Direct Current (MFDC) spot guns Slim profile for high density spacing and reduced SpotWorld workcell footprint •High-speed, light weight robots have reduced profile versus traditional high payload spot robots. They provide higher robot density and easily integrate into SpotWorlds®. •Expanded wrist motion range eliminates interference and improves application flexibility. •Up to 70% less power consumption SPECIFICATIONS during motion and 25% savings during idle periods compared to previous models. MS80W II payload: 80 kg with spot harness 88 kg without spot harness •Up to 30% faster than traditional MS100 II payload: 100 kg with spot harness 110 kg without spot harness •Servo gun cables and air and 2,236 mm horizontal reach 3,751 mm vertical reach ±0.07 mm repeatability Floor mounted water lines are routed through robot base and upper arm to increase cable life, enhance safety and reduce teaching time. •Digital interface provides simple CONTROLLERS size spot welding robots. DX200 FS100 MLX200 wiring to spot timers and allows weld programming from the robot pendant for Medar® and Nadex® brand timers. •Numerous spot welding functions to take advantage of servo gun control including: • Work thickness detection • Multi-step pressure file • Tip wear compensation • Work search function • Gun arm bending compensation • High-speed gun optimization software • Servo tip dresser •Spot harness connections • Connections from base to upper arm • DeviceNet signal and power • Connections from base to wrist (gun) • Servo motor and encoder • Air hose (2) 6.5 mm ID, (1) 8 mm ID • Water hose (4) 8 mm ID • Weld power (2) 22 mm2, (1) 14 mm2 • Transformer thermostat (3) 0.75 mm2 • User I/O (9) twisted pair + (1) 0.3 mm2 MS80W II | MS100 II ROBOTS 320 200 1020 VIEW A 125 Tapped holes M10(6holes),Depth:16mm Tapped holes M10(6holes),Depth:16mm Ø10 dia.(2holes),Depth:8mm C Device net CM02-8DR5P-CF(D5) Matching connector type is CM02A-8DP5S-D (provided by users) Internal user wiring connector (Base side) JL05-2A24-28PC (with cap) Matching connector type is JL05-6A24-28S (provided by users) 1295 JIS2 M4 1536 Water exhaust 1 PT1/2 with pipe plug Water inlet 1 PT1/2 with pipe plug JIS2 M4 Water inlet 2 PT1/2 with pipe plug C2BG36-36 JIS2 M4 JIS2 M4 JIS2 M4 JIS2 M4 JIS2 M4 JIS2 M4 Water exhaust 2 PT1/2 with pipe plug Air inlet PT3/8 with pipe plug 2237 0 3773 100 Ø12 dia.through holes (2holes) 195 ±0.1 455 385 210 228 C2BG36-36 559.2 63-63GB2C 36 ØTapped holes M8 (4holes), Depth:16mm 230 195 ±0.1 320 280 R22 255.5 270.2 100 230.5 99 230 ±0.1 VIEW C Air exhaust PT3/8 with pipe plug 195 540 966 VIEW B +24V connector CM03A-R4P-S-1 Matching connector type is CM03-P4S (provided by users) B 289 60 ° Ø160 Ø9 dia.(2holes),Depth:8mm 3751 870 235 2456 P-point 125 92 Ø210 A 400 195 153 230 455 608 MS100 II robot shown All dimensions are metric (mm) and for reference only. Request detailed drawings for all design/engineering requirements. 22 dia. through holes (8 holes) SPECIFICATIONS: MS80W II | MS100 II (WITH EXTERNAL CABLE) Axes Maximum motion range [°] Maximum speed [°/sec.] Allowable moment [N•m] Allowable moment of inertia [kg•m2] MS80W II MS100 II Controlled axes 6 6 Maximum payload [kg] 80 100 Repeatability [mm] ±0.07 ±0.07 Horizontal reach [mm] 2,236 2,236 Vertical reach [mm] 3,751 3,751 MS80W II MS100 II MS80W II MS100 II MS80W II MS100 II MS80W II MS100 II S ±180 ±180 170 140 – – – – L +155/-90 +155/-90 140 110 – – – – U +160/-185 +160/-185 160 130 – – – – Temperature [°C] 0 to +45 0 to +45 R ±205* ±205* 230 175 389 696 28 58 Humidity [%] 20 - 80 20 - 80 B ±120* ±120* 230 175 389 696 28 58 Weight [kg] 558 655 T ±180* ±180* 350 255 201 294 10.3 33 Power supply, average [kVA] 4 5 * Motion range limited by spot harness OPTIONS Yaskawa America, Inc. Motoman Robotics Division Extended length manipulator cables Robot risers and base plates External axis kits for servo guns Wide variety of fieldbus cards Vision systems Digital interface (Dnet or EIP) for Medar MedWeld 6000 spot timer TECHNICAL SPECIFICATIONS SUBJECT TO CHANGE WITHOUT NOTICE DS-606-B ©2015 YASKAWA AMERICA, INC. JANUARY 2015 AXES LEGEND S-Axis: Swivel Base L-Axis: Lower Arm U-Axis: Upper Arm R-Axis: Arm Roll B-Axis: Wrist Bend T-Axis: Tool Flange 100 Automation Way Miamisburg, OH 45342 Tel: 937.847.6200 Fax: 937.847.6277 motoman.com MOTOMAN IS A REGISTERED TRADEMARK ALL OTHER MARKS ARE TRADEMARKS AND REGISTERED TRADEMARKS OF THEIR RESPECTIVE OWNERS.

© Copyright 2026