Crystallite size vs grain size Infinite crystal

Crystallite size vs grain size • Not equal, a grain can contain several crystallites Infinite crystal • Electron density can be described to be proportional to (r-rpqr). • Scattering amplitude is then proportional to (q-r*hkl). One dimensional 1 Shape of the crystallites • The electron density of a crystallite can be presented as a product of the lattice term (r) of the infinitely large crystal and the shape function (r) of the crystallite. • ( r)= (r)·( r) (r)=1 inside the crystallite and 0 outside. Amplitude F of crystallite • F(q) = (r) (r) exp(i q·r) d3r • Using convolution theorem of Fourier transform: F(q) = F (q)* (q). The star * denotes convolution. • The function (q) = (r) exp(i q·r) d3r • Intensity I(q) = F*(q) F(q). 2 Convolution theorem Consider functions of one variable f and g. Their convolution is f*g(x) = f(u)g(x-u)du. Fourier transform F(f*g) = f*g(x)exp(-ikx) dx = dx du f(u)g(x-u) exp(-ikx). Change of variable x-u = y. F(f*g)(k) = dy du f(u)g(y) exp(-ik(y+u)) = du f(u) exp(-iky) du g(y) exp(-iku) = Ff(k)·Fg(k). Intensity of small crystallite Patterson function P(r) = (u) (u+r) (u) (u+r) d3u = V (u) (u+r)>, where V is the volume limited by the shape function. 3 Intensity • I N/V F2 Z(q) * | (q)|2 • F2 unit cell structure factor • Z(q) lattice term • (q)|2 broadening due to limited size. Integrated intensity Z(q) = sin(½(N1-1)q·a) /sin(½ q·a) sin(½(N2-1)q·b) /sin(½ q·b) sin(½(N3-1)q·c) /sin(½ q·c) Set N1=N2=N3=N. The maximum intensity at a Bragg peak can be shown to be equal to f2N2. The width of the peak is aproximately proportional to 1/N. The integrated intensity (the area of the peak) increases proportional to N. 4 Crystallite size • Form factor of a sphere F(x) = 4/3 a3 3 (sin x –x cos x)/x3, where x = qa. • Reflection spot in reciprocal space is approximated as a sphere, radius dq. • The width of F(x)2 gives the angular width of the diffraction peak 2 dq/(cos q0) • q0 = 2 , 2dq = 3.6/R • Angular width d(2 ) = 0.57 /(R cos ) Crystallite size: simple approach • Let m be the number of parallel planes • Let 1 present the highest angle (1) and 2 the lowest angle (2) one can go before getting destructive interference. • The path differences are (m+1) and (m-1) . • Destructive interference with planes in the middle of the crystallite with path differences (m+1) /2 and (m-1) /2. B t=md 5 Crystallite size We assume triangular shape for the diffraction peak, FWHM = B = (2 1-2 2)/2= 1 2. Path length differences between rays scattered from the front and back planes of the crystallite 2 t sin 1 = (m+1) 2 t sin 2 = (m-1) t(sin 1 - sin 2 ) = 2t cos(( 1 + 2)/2) sin (( By approximating one obtains 2t ( t = /B cos 1 1 + 2)/2) 1 2)/2 2)/2 cos = = B and sin x B = B The average size of crystallites • Assume a powder sample of crystallites of the same size N1=N2=N3=N. • In a powder crystallites take all orientations. Thus one may consider only one rocking crystallite. • Let qhkl be the reciprocal lattice vector for the reflection hkl. • Let the directions of the primary and diffracted beams vary slightly. Name q’ = q + q and s’-s’0 = s-s0 s. 6 Scherrer equation Approximate sin2(Nx)/ sin2x N2exp(-(Nx)2 ) The intensity I sin2(Nq·a)/ sin2q·a sin2(Nq·b)/ sin2q·b sin2(Nq·c)/ sin2q·c becomes I IeF2N6 exp(-( 2) N2(( s·a)2+( s·b)2+( s·c)2), since sin2(qhkl+2 s/ )·Nq/2 = sin2 (hN+ sNa/ )·Nq/2 = sin2 s·Na). Setting a=b=c, I IeF2N6 exp(-( 2) (Na)2 q)2) Scherrer equation It is easier to rock the q-vector than the crystallite. The difference vector is denoted by s = x+y+ , and s2 = (xsin )2+y2+( cos )2 The intensity at fixed departure is proportional to the sum of all values x and y. I IeF2N6 exp(-( 2)(Na)2 cos )2) 2 2 2 exp(-( )(Na) (x- sin ) )dx exp(-( 2) (Na)2y2)dy. The intensity becomes proportional to I K exp(-( 2)(Na)2 cos )2) , where K is a constant. This function is a gaussian and and its FWHM is obtained from 1/2 = exp(-( 2)(Na)2 cos )2). y x s’-s0 q s’ s The broadening of the peak B(2 ) is about 2 . 7 FWHM of Gaussian • • • • f(x) = exp(-x2/b2) FWHM in terms of b: exp(-x2/b2)= ½ => x2 = ln 2 b2 FWHM = 2x = 2(ln2)1/2 b Scherrer equation • B(2 ) = 2(ln2/ )1/2 /Na cos . • Set L = Na => Scherrer equation B(2 ) = 0.94 /(L cos ), where B is the FWHM of the reflection • More details in Warren, X-ray diffraction, chapter 13 8 Stokes and Wilson • Let P(2 ) be the measured intensity of a reflection. • Broadening has been also described as (2 ) = P(2 )d(2 )/max(P(2 )) • B(2 ) = /(L cos ) Experimental determination 1. Subtraction of background 2. Determination of maximum intensity: statistical accuracy must be quite good 3. Determination of the FWHM: the angular (q-scale) step must be small enough compared to the width of the peak 4. Instrumental broadening affects also the width 9 Instrumental broadening • Let g(x) be the measured curve. • Instrumental broadening is presented as an integral equation g(x) = h(x,y) f(y) dy + n(x), where f is the exact result, h the instrumental function (kernel), and n statistical errors. • If the effect of the instrument is the same in all points, the integral equation is of convolution type: g(x) = h(x-y) f(y) dy. Special solution for this case • Sometimes it can be assumed that both the diffraction peak and the instrumental function are Gaussians. For the FWHM of a convolution of two Gaussians f and g holds: f*g2 = f2 + g2 • For some other setups the peaks might be approximated as Lorenz (Cauchy) functions 1/(1+a2x2). • Then f*g = f + g. 10 Convolution of Gaussians • f(x) = exp(-x2/b2) • FWHM in terms of b: exp(-x2/b2)= ½ => x2 = ln 2 b2 • FWHM = 2x = 2(ln2)1/2 b • g= exp(-x2/d2) • f*g = constant exp(-y2/(b2+d2)) Effect of strain on diffraction peak 11 Broadening of reflection: strain • No strain, the position of the peak q = /d, where d is the distance of the lattice planes • Uniform strain: d increases => q decreases. • Non-unform strain: d varies: If <d>=d, the position may not change, but the FWHM of the peak increases. Broadening • Bragg law 2d sin = • Differentiate 2 d sin + 2d cos • d/d tan = 2 =0 12 Size distribution for crystallites • By fitting a simulated powder pattern, derived from an appropriate physical model, to experimental data. • dislocations and other lattice distortions • Model shapes for size distributions – Gaussian G(x) = (2 b2)-1/2 exp(-(x-a)2 /2b2) – Lognormal f = 1/(r(2 ln(1+c))1/2 exp(ln(r/<r>(1+c)1/2)2/(2ln(1+c))); Size-strain line broadening For analysing line broadening, correction for instrumental broadening must be done first. – Wavelength dispersion – Slits Deconvolution, ill-posed problem: good measurements are essential! Voight function is usually assumed for the line shape in the powder diffraction refinement programs. 13 Broadening: size, strain • Size (Scherrer): FWHM proportional to 1/cos • Strain: FWHM proportional to tan • Measure peaks, e.g. 00l. • Determine the widths • Plot the width as a function of l (or angle) • Study the angular dependence. Profile fitting • Lorenzian (Cauchy function) FWHM = A/cos + B tan + C • Voight function FWHM = U tan2 + V tan + W + P/cos2 14 Good references • J. I. Langford, D. Louër and P. Scardi. Effect of a crystallite size distribution on X-ray diffraction line profiles and whole-powder-pattern fitting. J. Appl. Cryst. (2000). 33, 964-974 • D. Balzar et al. Size-strain line-broadening analysis of the caria round-robin sample. J. Appl. Cryst. 2004, 37, 911-924. • Ungar et al. Crystallite size distribution and dislocation structure determined by diffraction profile analysis: principles and practical application to cubic and hexagonal crystals. J. Appl. Cryst. 2001, 34, 298-310. Diffraction pattern of wood 002 q=4 003 sin q -110 Reflection 004 110 Reflection 200 102 15 Monoclinic Cellulose I 004 C-axis 200 In-situ X-ray diffraction and tensile testing • Stress-strain curves from tensile testing give information on the deformation of the macroscopical sample • X-ray diffraction (XRD) gives the the behaviour of crystalline cellulose under tension. 16 Comparison of ESRF and HASYLAB ID13 at ESRF, France A2 at Hasylab, Germany Undulator Bending magnet 5 µm beam 250x 250 µm beam 0.96 Å (13 keV) 1.5 Å (8 keV) stretching rate 0.2 µm/s, meas. Time 21 s stretching rate 0.2 µm/s, measuring time <10 s Beamline A2 Early wood, year ring 4, initial MFA 9º • Reflection 004 moved to smaller scattering angles: elongation of cellulose chain (0.5%) • Width increased: strain • Intensity decreased: lattice distortions 004 ESRF 17 Warren-Averbach • Profile of Bragg reflection P(q) is assumed as a convolution of profiles presenting strain and size distortion. • P(dqi) = const A(l,dqi) cos(qL) + B(L,dqi) sin(Lq), where L gives the distance perpendicular to the diffracting planes and dq is the deviation from the reflection position. • Fourier transform of the profile gives for the Fourier coefficients A(L) and B(L). Usually only A(L) are considered. • ln A(L) = ln ALs - 2 2 L2 g2 <e2>, where ALs are size coefficients, g the absolute value of the scattering vector, and <e2> is the mean square strain. The parameter L is defined as L=na3, where a3 = (sin 2-sin 1), n integer. Warren-Averbach • To obtain information on size and distortion coefficients, at least two orders of reflection have to be measured. • See e.g. Warren: X-ray diffraction, Berkum et al. Applicabilities of the Warren-Averbach analysis and an alternative analysis for separation of size and strain broadening. J. Appl. Cryst. 1994, 27, 345-357. 18 XRD and elastic properties • • • • 1-d case, stretched cylinder Force F in y-direction Tension F/A Increase of length y = L/L, where L is the length of the cylinder. • Hooke’s law F/A = E y, where E is Young’s modulus and A the area of the cross section of the cylinder. • For a cylinder x= y = D/D = - y, where D is the diameter and is the Poisson ratio. y F L Elastic properties • Determining relative increase of length using x-rays. Determine change of lattice spacing d/d of lattice planes perpendicular to the force F. • F/A = E/ d/d. 19 Residual stress • When metal bar is deformed (applied stress) it causes inner stress. • Microstrain: Lattice planes are deformed, d varies. • Macrostrain: Distance of lattice planes increases uniformly. 20

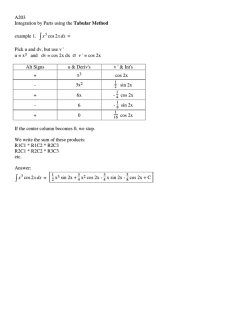

© Copyright 2026