WAFIOS In-House Exhibition 2015

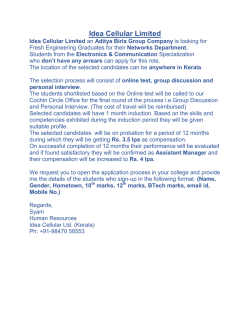

NEWS 04 2015 Promoted to an Industry Meeting WAFIOS In-House Exhibition 2015 The WAFIOS in-house exhibitions have become a fixed date in the calendar for experts in the field of forming technology and have established themselves as an industry platform. Also for this year's event, which take place in Wuppertal from the 6th to the 9 th of May, WAFIOS once again promises visitors from all around the world interesting presentations and innovative technologies Finished Parts with no Post-processing One of the highlights will be the SMR Forming Center. The machine serves for the production of very small parts, M0.6 to M3 and can achieve speeds of 400 parts per minute. WAFIOS Umformtechnik has developed a unique concept with the SMR which combines cold forming and post-processing operations – and that without the need to re-load the miniature parts. The result: finished parts with no post-processing whereby no washing process is necessary between the forming, sawing and thread rolling. A rotor with hydrostatic bearings with up to 8 dies ensures the highest precision. Machine Exhibition and Specialist Presentations Furthermore, in addition to the extensive display of machines at the WAFIOS in-house exhibition, the 2-die, 3-blow HC5FT forming machine with induction heating will be presented, the world's fastest machine of this type (up to a maximum of 400 parts per minute). Specialist presentations on current themes are included in the supporting programme. Guest speakers and WAFIOS Umformtechnik specialists provide information about the latest trends and give insights into the technologies and backgrounds. Registration is possible under: [email protected]. WAFIOS Umformtechnik In-House Exhibition: 06. – 09.05.2015 We are looking forward to your visit. Please register to: WAFIOS Umformtechnik GmbH Tessa Schubert Im Rehsiepen 35 · 42369 Wuppertal ■ NEWS 04 Phone +49 (202) 4668-218 Fax +49 (202) 4668-225 [email protected] 2015 www.wafios-umformtechnik.com www.hausmesse.wafios.com Excerpt of lectures: Formability of high strength steels and special materials (WAFIOS Umformtechnik GmbH) Requirements of modern metalworking – A challenge for the lubrication (Bechem GmbH) Simulation of hot and cold forming – practical application examples (CPM Ges. für Computeranwendung) Partners on the exhibition: Schwer & Kopka GmbH (Process Controlling) Himmelwerk GmbH (High- and Medium Frequency Technology) Carl Bechem (Lubricants) CPM Ges. für Computeranwendung (Simulation) Künne Gruppe (Unalloyed patented spring steel wires, Cable wires, Iron- and cold swaged wires) www.wafios-umformtechnik.com ■ 1 induction heating THE HEATING OF SPECIAL MATERIALS BY INDUCTION How does induction heating work? The induction heating of the wire is essential in many cases in order to be able to guarantee the subsequent forming of special materials. Why induction heating? In the following diagram the effect of temperature on the tensile strength of the material is represented. The reduction in the tensile strength with increasing temperature can be clearly seen. In this way the forming forces can be so reduced and cracks in the material while forming can be avoided. Therefore the processing of special materials (for example, Inconel, titanium and stainless steel) is possible on WAFIOS Umformtechnik machines. Inductor Pyrometer Shearing Impact Extrusion First Punch Second Punch Inductor Coil WAFIOS Umformtechnik, with its many years of experience in this field, has integrated this technology in the area of hot working (up to approx. 900°C) and semi-hot working (up to approx. 300°C) in its KIESERLING and HILGELAND brand forming machines. The induction coil is located, as shown in the illustration, immediately before the cut-off station to avoid heat losses. An induction coil generates an alternating magnetic field and transfers the necessary energy contactlessly to the wire fed into it, through this the wire heats up and can be accordingly formed with lower press force. The temperature of the wire can be accurately controlled via the control technology. Effect of temperature on the tensile strength of materials 500 450 400 Festigkeit N/mm² 350 300 2.4816 250 Induction heating for what? With this integrable technology for induction heating, WAFIOS Umformtechnik is opening up new perspectives for various applications in the industry. Examples of applications can be found with special materials, for example, in sectors in the automotive industry, aeronautical and aerospace engineering, electrical / electronics industries and also medical engineering. Many well-known manufacturers in these industry sectors use WAFIOS Umformtechnik forming machines with induction heating all over the world to form high-strength materials at high speed. Visit our in-house exhibition in Wuppertal, Germany on 06th - 09th May 2015 Excerpt of exhibits: HC5FT 2-die-3-blow Cold Former: With Induction Heating. Double-stroke Cold Former HC800 with rotary die block: Fastest in its category with new space saving design. Forming Center SMR for the production of micro-parts M0.6 – M3: Headed – Slotted – Threaded – Finished parts exit the machine. Automatic Pointer SKM 08: The economical solution for machining shaft ends. Nut Tapper MAS 33F: Universal and efficient applicable until M33. Nut Tapper UNT 12: Especially for long parts with blind hole. FN12 Thread Roller: Delta PT Thread Rolling Dies. 3.7165 1.4567 200 150 100 50 Nailmaster und Threadmaster: Space saving combination with an output rate up to 1400 threaded nails per minute. 0 20 100 200 300 700 800 850 900 950 1000 1050 Temperatur °C 2 ■ www.wafios-umformtechnik.com ■ NEWS 04 2015 Nail Machines New machines for the nail industry WAFIOS Umformtechnik Takes Over the Nail Machine Programme of WAFIOS AG In the future, in addition to the machines from HILGELAND, KIESERLING, NUTAP und MRP, the nail machine Series N, N 90, NAILMASTER and the thread rolling machines THREADMASTER and GW 92 will be found under the umbrella of WAFIOS Umformtechnik GmbH in Wuppertal. The nail machines working on the single stroke process round off the cold forming machine programme of HILGELAND and KIESERLING perfectly. WAFIOS Umformtechnik has many years experience in the manufacture and distribution of mechanical forming machines for the production of screws and fasteners of all types. For this reason WAFIOS AG has decided to transfer the complete nail machine programme to WAFIOS Umformtechnik. In the first step, sales, design, production, procurement and assembly of the nail machine programme was transferred on the 1.1.2015. The transfer of the spare parts and service business for the nail machines will follow on the 1.7.2015 and the transfer will then be completely finished. Since January, 2015 Mr. Julian Peinke has been the direct contact person at WAFIOS Umformtechnik GmbH for sales of new machines for the nail industry. Sales of new machines for the nail industry: Mr. Julian Peinke Phone +49 202 4668 268, Email: [email protected] Please come and talk to our experts WAFIOS Umformtechnik at other fairs Fastener Expo Shanghai, China 25.06. – 27.06.2015 Booth 1F 01 FASTENER TECH TM 2015, Rosemont Chicago, IL, USA, 08.06. – 10.06.2015 Hall F Booth 823 / 924 25 - 27 June Please visit us at stand: Legal Notice Responsibility for Content of Newsletter: WAFIOS Umformtechnik GmbH, 42369 Wuppertal / Germany Text: Dirk Zandecki, Werbung & PR für Technik Layout: KS-GDesign· Karola Schindler WAFIOS Umformtechnik GmbH Im Rehsiepen 35 42369 Wuppertal Phone +49 (202) 46 68-0 Fax +49 (202) 46 68-225 1 F 01 ■ NEWS 04 2015 Hilgeland Kieserling MRP Nutap 3 ■ www.wafios-umformtechnik.com [email protected] www.wafios-umformtechnik.com Germany

© Copyright 2026