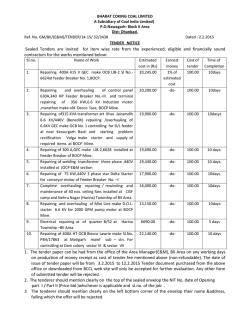

Milling Tools given in Annexure-I