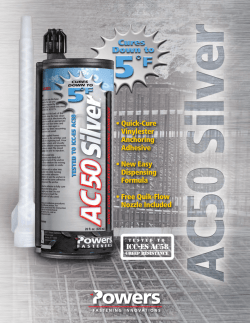

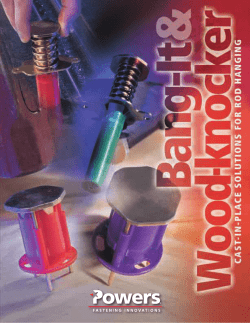

Adhesive Anchors - Powers Fasteners