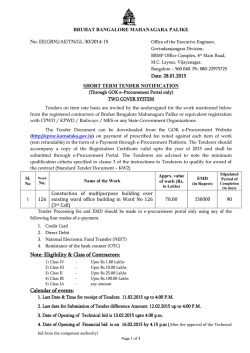

OFFICE OF THE TEXTILE COMMISSIONER - BTRA