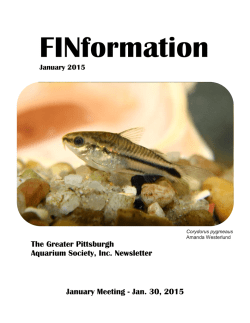

2015 sustainability report