QUEMADORES DE SECADORES DE AGREGADOS

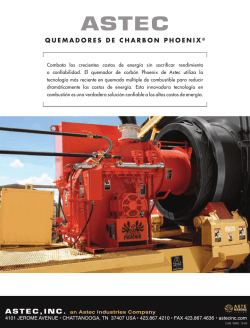

Aggregate Drying Burners Quemador de secadores de agregados ASTEC QUEMADORES AGREGADOS A G G R E G A DE T ESECADORES D R Y I N G DE BU RNERS P ara pl antas de as f a lt o d e m eFacilities z c la e n c a lie n t e For Hot Mix Asphalt ASTEC A S T E C P E R F I L D E L A C O M PA Ñ Í A Astec, Inc. diseña, fabrica y comercializa plantas de asfalto de mezcla en caliente con proceso batch y continuo, equipo de remediación de suelos y componentes relacionados. Astec, Inc. se ha convertido en el líder del mercado en plantas de asfalto de mezcla en caliente al ser una empresa impulsada por los clientes. Al escuchar a nuestros clientes y comprender cada aspecto de sus negocios, somos capaces de proporcionar productos nuevos que resuelven sus problemas y mejoran su rentabilidad. El grupo de ingenieros de quemadores de Astec, Inc. trabaja junto con los clientes para desarrollar sistemas de quemadores que cubran diversas necesidades. Cada quemador es examinado antes de abandonar las instalaciones para asegurar un funcionamiento rápido y sencillo durante su instalación. Los quemadores de Astec son avanzados tecnológicamente y respaldados por el excelente servicio de Astec . ASTEC ASTEC PHOENIX® COAL QUEMADORES DE CHARBON PHOENIX® Combat the rising cost of energy without cing performance reliability. Astec Combata lossacrifi crecientes costos de or energía sin The sacrifi car rendimiento Phoenix Coal burner the latest multiple-fuel o confiabilidad. El quemador deuses carbón Phoenix de Astec utiliza la burning technology to dramatically lower energy tecnología más reciente en quemado múltiple de combustible para reducir dramáticamente costos de energía. Esta innovadora costs.losThis innovative combustion technology istecnología en combustión esauna soluciónto confi able a los altos costos de energía. trulyverdadera reliable answer high energy costs. 2.5M. WMS. 12-06 LATEST COMBUSTION LA TECNOLOGÍA EN TECHNOLOGY COMBUSTIÓN MÁS LATEST COMBUSTION TECHNOLOGY Designed to burn bituminous coal, the Phoenix Coal’s MODERNA LATEST COMBUSTION TECHNOLOGY Designed to burn bituminous coal, the elPhoenix Coal’s Diseñado para quemar carbón bituminoso, sistema combustión combustion system uses a coal preparation skidde that LATEST COMBUSTION TECHNOLOGY Designed to burn bituminous coal, the Phoenix Coal’s PCPC 150 PC150 125 PC 100 PC100 75PC PC 150 150 PC PC 125 125 PC PC 100 100 PC 75PC 75 MODEL MODEL PC PC 125 PC 75MODEL MODEL PC150 PC125 PC100 PC75 MODELO del quemadorsystem de carbón Phoenix implementa un depósito combustion uses coal a coal preparation skid that con la pulverizestoand delivers as the the burner demand Designed burn bituminous coal, Phoenix Coal’s combustion system uses apulveriza coal preparation skid that según la preparaciónand de carbón quecoal suministra carbón pulverizes delivers as feature they burner demand requires it. Another innovative of the Phoenix combustion system uses a coal preparation skid that demanda del quemador. Otra característica innovadora del quemador pulverizes delivers coal asfeature the burner demand requires it. and Another innovative of the Phoenix Coal burner is that does use a refractory de carbón Phoenix esit que nonot utiliza una cámara de combustión pulverizes and delivers coal as the burner demand requires it. Another feature of the Phoenix Coal burner is that itinnovative does not use a refractory refractaria. combustion chamber. requires it. Another innovative feature of the Phoenix Coal burnerchamber. is that it does not use a refractory combustion Coal burnerchamber. is that it does not use a refractory combustion OPCIONES MÚLTIPLES MULTIPLE FUEL OPTIONSEN COMBUSTIBLE combustion chamber. MULTIPLE FUEL OPTIONS El quemador de carbón Phoenix utiliza gas, nº 2, gasóleo The Phoenix Coal Burner uses either Gas,aceite #2 Oil, MULTIPLE FUEL OPTIONS reciclado o aceite pesado como combustible de ayuda para la The Phoenix usesOil either #2 Oil, Recycled FuelCoal Oil,Burner orOPTIONS Heavy as aGas, support fuel for MULTIPLE FUEL ignición continua del Burner carbón bituminoso El quemador de The Phoenix Coal usesOil either #2 fuel Oil, Recycled Fuel Oil, or Heavy aspulverizado. aGas, support for continuous ignition ofpuede the uses pulverized bituminous coal. The Phoenix Coal Burner either Gas, #2 Oil, carbón Phoenix también encenderse a una capacidad Recycled Fuel Oil, or Heavy Oil as a support fuel for nominal continuous ignition of the pulverized coal. The Phoenix Coal burner can also fide rebituminous at 100% of rated del 100% para abastecer al combustible ayuda enfuel caso de que el Recycled Fuel Oil, or Heavy Oil as a support for continuous ignition of the can pulverized bituminous coal. The Phoenix Coal burner also fi re at 100% of rated suministro de carbón no se encuentre disponible. capacity onignition the support if the coal supply is coal. continuous of thefuel pulverized The Phoenix Coal burner can firebituminous at 100%isof rated capacity on the support fuel ifalso the coal supply The Phoenix Coal burner can also fi re at 100% not available. capacity on COMPACTA the support fuel ifDE the coal isof rated FORMA LA supply LLAMA not available. capacity on the support fuel if the coal supply is El innovador diseño compacto del quemador y su sistema de combustión not available. COMPACT FLAME SHAPE not available. también produce una llama compacta que puede adaptarse fácilmente COMPACT FLAME SHAPE The innovative compact design ofdethe burner and its a los diseños modernos de secadores agregado. COMPACT FLAME SHAPE The innovative compact design of the burner combustion system also SHAPE produces a compact and flameitsthat is COMPACT FLAME The innovative compact design of the burner and combustion systemDEL also TUBO producesDE a compact flameits that is EMISIONES ESCAPE NO The innovative compact design of the burner easily adapted to modern aggregate dryer designs. combustion system also produces a compact fland ameitsthat is easily adapted to modern aggregate dryer designs. VISIBLES combustion system also produces a compact flame that is easily adapted to modern aggregate designs. El quemador Phoenix produce emisionesdryer que se comparan con NO VISIBLE STACK EMISSIONS easily adapted to modern aggregate dryer designs. NO VISIBLE STACK EMISSIONS aquellas que se alcanzan cuando se quema aceite para The Phoenix Coal produces emissions comparableusado to those NO VISIBLE STACK EMISSIONS usar como combustible. De hecho, el Phoenix no genera humo. Las The Phoenix Coal produces emissions achieved when burning waste oil as acomparable fuel. In fact, to thethose Phoenix NO VISIBLE STACK EMISSIONS emisiones del tubo de escape alcanzan una opacidad del 0%, lo que The Phoenix Coal produces emissions to those achieved when burning waste oilemissions as a comparable fuel.are In fact, theopacity, Phoenix Coal produces no smoke. Stack at 0% The Phoenix Coal produces emissions comparable to those significa una visibilidad óptima a través del penacho de humos. achieved when burning waste oil as a fuel. In fact, the Phoenix Coal produces nobut smoke. Stack emissions are the at 0% opacity, meaning nothing skywaste can be seen through plume. achieved when burning oil as a fuel. In fact, the Phoenix Coal produces nobut smoke. Stack are the at 0% opacity, meaning nothing sky can be emissions seen through plume. Coal produces no smoke. Stack are at 0% opacity, ESPECIFICACIONES DEemissions LA COMBUSTIÓN meaning nothing but sky can be seen through the plume. CON BAJO EXCESO DE AIRE meaning nothing but sky can be seen through the plume. Capacidad LOW EXCESS AIR FIRING SPECS Aire de la atom. Capacidad de secado Capacidad del LOW EXCESS AIR Potencia FIRING SPECS de aceite m3/min nominal en de agregado de aire del ventilador RatedkW Capacity Nominal Aggregate Burner FIRING Air IntegralSPECS Oil Atomizing LOW EXCESS AIR (con nominal a 5% quemador interno en Millions of Capacity Capacity Blower SPECS Air 20%Capacity de XSA) deDrying humedad m3/min kW Integral Rated Nominal Aggregate Burner Air OilRequirement Atomizing LOW EXCESS AIR FIRING Fuego bajo Fuego alto BTU/HR at(mtph) 5% Moisture SCFHAir Horsepower SCFM Millions of Nominal Drying Capacity Burner Capacity Blower Air Rated Capacity Aggregate Integral OilRequirement Atomizing (with 20% XSA) Low Fire High Fire BTU/HR at 5% Moisture SCFH Horsepower SCFM Millions of Nominal Drying Aggregate Capacity Burner Capacity Blower Air Rated Capacity Air Integral OilRequirement Atomizing (with 20% XSA) High Fire BTU/HR at 5% Moisture SCFH Horsepower SCFM Millions of Drying Capacity Capacity Blower Low Air Fire Requirement 21961 566 SCFH 56 2.8 2.3Fire (withBTU/HR 20% XSA) at272 Low Fire High 5% Moisture 75 300 tph 20,000 Horsepower 75 100SCFM 80 (with 20% XSA) Low Fire High Fire 75 300 tph 20,000 75 100 80 75 300 tph 20,000 75 100 80 29281 363 75520,000 75 75 2.8 100 2.3 75 300 80 100 400 tph tph 26,667 75 100 80 100 400 tph 26,667 75 100 80 100 400 tph 26,667 75 100 80 36601 454 100 400 75 2.8 100 80 125 500 tph tph 94626,667 33,417 93 100 100 2.3 80 125 500 tph 33,417 100 100 80 125 500 tph 33,417 100 100 80 125 500 tph 1,137 33,417112 100 3.5 100 2.5 80 43982 544 150 600 tph 40,167 125 125 90 150 600 tph 40,167 125 125 90 Las condiciones anteriores son estándares a 21 °C del nivel del mar. Vea la capacidad detallada, las hojas de rendimiento de cada 150 600 tph 40,167 125 125 90 $ERYHFRQGLWLRQVDUHVWDQGDUGDWÜ)DWVHDOHYHO6HHGHWDLOHGFDSDFLW\SHUIRUPDQFHVKHHWVIRUHDFKVL]H tamaño para obtener más información y flujos y presiones específicas. La capacidad de secado del agregado nominal en base a las IRUPRUHLQIRUPDWLRQDQGVSHFLÀFÁRZVDQGSUHVVXUHV1RPLQDODJJUHJDWHGU\LQJFDSDFLW\EDVHGRQW\SLFDO temperaturas típicas del tubo de escape600 de 115.6° C, 0.2 cal/g °C de calor específico en 125 el agregado. La capacidad 150 tph 40,167 125máxima del90 $ERYHFRQGLWLRQVDUHVWDQGDUGDWÜ)DWVHDOHYHO6HHGHWDLOHGFDSDFLW\SHUIRUPDQFHVKHHWVIRUHDFKVL]H H[KDXVWVWDFNWHPSHUDWXUHVRIÜ)%78/EP)VSHFLÀ FKHDWLQWKHDJJUHJDWH%XUQHUPD[LPXP diseño del quemador es 110% de la capacidad nominal. IRUPRUHLQIRUPDWLRQDQGVSHFLÀ FÁRZVDQGSUHVVXUHV1RPLQDODJJUHJDWHGU\LQJFDSDFLW\EDVHGRQW\SLFDO GHVLJQFDSDFLW\LVRIUDWHGFDSDFLW\ $ERYHFRQGLWLRQVDUHVWDQGDUGDWÜ)DWVHDOHYHO6HHGHWDLOHGFDSDFLW\SHUIRUPDQFHVKHHWVIRUHDFKVL]H H[KDXVWVWDFNWHPSHUDWXUHVRIÜ)%78/EP)VSHFLÀFKHDWLQWKHDJJUHJDWH%XUQHUPD[LPXP IRUPRUHLQIRUPDWLRQDQGVSHFLÀ FÁRZVDQGSUHVVXUHV1RPLQDODJJUHJDWHGU\LQJFDSDFLW\EDVHGRQW\SLFDO GHVLJQFDSDFLW\LVRIUDWHGFDSDFLW\ $ERYHFRQGLWLRQVDUHVWDQGDUGDWÜ)DWVHDOHYHO6HHGHWDLOHGFDSDFLW\SHUIRUPDQFHVKHHWVIRUHDFKVL]H H[KDXVWVWDFNWHPSHUDWXUHVRIÜ)%78/EP)VSHFLÀFKHDWLQWKHDJJUHJDWH%XUQHUPD[LPXP IRUPRUHLQIRUPDWLRQDQGVSHFLÀ FÁRZVDQGSUHVVXUHV1RPLQDODJJUHJDWHGU\LQJFDSDFLW\EDVHGRQW\SLFDO GHVLJQFDSDFLW\LVRIUDWHGFDSDFLW\ H[KDXVWVWDFNWHPSHUDWXUHVRIÜ)%78/EP)VSHFLÀFKHDWLQWKHDJJUHJDWH%XUQHUPD[LPXP GHVLJQFDSDFLW\LVRIUDWHGFDSDFLW\ COAL COAL COAL COAL ® ® ® ® Over 90% of the United States can be permitted to burn coal. Over 90%del of 90% the United be permitted to Alrededor de los States Estadoscan Unidos tiene burn coal. Over 90% of quemar the United States can be permitted to permiso para carbón. burn coal. Over 90% of the United States can be permitted to burn coal. The coal prep skid pulverizes the coal for use by the burner. The coal prep skid pulverizes the coal for use by thedepósito burner. The coal prep pulverizesdethecarbón coal for use by El con skid la preparación pulveriza thecarbón burner. The coal prep pulverizes the coal for use by el que seskid usará en el quemador. the burner. Astec frequently tests burners before shipping to ensurefrequently quality. tests burners before shipping to Astec ensure frequently quality. tests burners before shipping to Astec ensure quality. Astec frequently tests burners before shipping A menudo, Astec prueba los quemadores antes de to ensure quality. enviarlos para garantizar su calidad. ASTEC ASTEC PHOENIX® TALON Q U E M A D O R E S P H O E N I X ® TA L O N The Astec Phoenix Talon utilizes the latest burner deliver very low emissions El Phoenix Talon de technology Astec utiliza to la tecnología más reciente de quemadores combined Withenthecombinación con para suministrar muy with bajosenergy niveleseffi deciency. emisiones optional silencing it’s even buena eficiencia en el consumopackage, de energía. Con elpossible paquete silenciador opcional, es posible mantener una conversación telefónica en la to have a phone conversation on the burner plataformaplatform del quemador está en funcionamiento. while mientras it is firing. 2.5M. WMS. 12-06 ADVANCED REDUCTION ADVANCED EMISSION REDUCTION REDUCCIÓNEMISSION AVANZADA DE LAS EMISIONES La serie PhoenixTalon Talonseries utiliza una mezcla de aire y combustible The Phoenix uses precise, high quality The Phoenix Talon series uses precise, high quality gaseoso ADVANCED EMISSION REDUCTION precisa yofdeair alta calidad para alcanzar una importante reducción de mixing and gaseous fuel to remarkable mixing of air and gaseous fuelprecise, to achieve achieve remarkable The Phoenix Talon series uses high quality las emisiones. Los inyectores de gas radiales mezclan completamente emission reduction. Radial gas injectors thoroughly mix air emission Radial gas to injectors thoroughly airLa mixing air and gaseous fuel achieve remarkable el aire y of el reduction. combustible para alcanzar bajos niveles de CO y mix NOx. and fuel for low CO and NOx emissions. The advanced and fuel for low CO and NOx emissions. The advanced tecnología avanzada deRadial emisiones se limita althoroughly combustible gaseoso. emission reduction. gasnoinjectors mix air emission technology is not limited to gaseous fuel. The El diseño avanzado del sistema de aire comprimido, de la boquilla de emission technology is not limited to gaseous fuel. The and fuel for low CO and NOx emissions. The advanced aceite y de la turbina hace posible que se logre una autorecirculación advanced compressed air, oil nozzle and air swirler design advancedtechnology compressed air, limited oil nozzle and air fuel. swirler emission not gaseous Thedesign y combustión muy rápidaisen algunos de to los sistemas de emisiones más achieves self-recirculation and very rapid burning for some achieves self-recirculation very rapid burning fordesign some advanced compressed air,and oil nozzle and air swirler bajos en combustión de aceite disponibles en la actualidad. of oil available today. of the the lowest lowest oil fifiring ring emissions emissions available today. for some achieves self-recirculation and very rapid burning EFICIENCIA EN ALIMENTACIÓN ELÉCTRICA of the lowest POWER oil firing emissions available today. ELECTRIC EFFICIENCY TALON TALON ® ® ® ® ELECTRIC POWER EFFICIENCY El mando de velocidad variable del ventilador principal de combustión ELECTRIC POWER EFFICIENCY suministra un control del régimen delblower fuego ydrive consume mucha The variable speed main combustion helps The variable speedexacto mainEFFICIENCY combustion blower drive helps ELECTRIC POWER menos energía. Tampoco es necesario un regulador de aire ni realizar provide precise fifiring rate control uses cantly provide precise ring ratecombustion control and andblower uses signifi signifi The variable speed main drivecantly helps ajustes ni mantenimientos del motor de tracción. less electrical energy. ItIt also eliminates the need for an less electrical energy. also eliminates the need for an air air provide precise firing rate control and uses significantly damper and for drive motor adjustments and maintenance. EFICIENCIA DE COMBUSTIÓN Yand LLAMA damper and for drive adjustmentsthe maintenance. less electrical energy. Itmotor also eliminates need for an air COMPACTA damper for drive motor&adjustments andFLAME maintenance. FIRINGand EFFICIENCY COMPACT SIZE FIRING EFFICIENCY FLAME SIZE La mezcla de aire y combustible& alta calidad genera la llama más FIRING EFFICIENCY &deCOMPACT COMPACT FLAME SIZE High quality mixing of fuel the most compact compacta disponible, unaand zona decreates combustión pequeña. Esto High quality mixingcon of air air and fuel creates the most compact FIRING EFFICIENCY & COMPACT FLAME SIZE garantiza que el combustible se queme totalmente para lograr la mayor flflame available with aa small combustion zone. This amequality available withof small combustion zone. This ensures ensures High mixing air and fuel creates the most eficiencia sin disminuir la valiosa capacidad de calentamiento concompact secador. that all of the fuel is combusted for peak effi ciency without of the fuel is combusted for peak zone. efficiency flthat ameallavailable with a small combustion This without ensures taking away valuable dryer capacity. COMBUSTIÓN taking dryer heating heating capacity. that all away of the valuable fuel is CONFIABLE combusted for peak efficiency without The swirler and other components of the nose ensure La y otros componentes del extremo garantizan The swirler and components of ensure Theturbina swirler and other other components of the the nose nose ensure flame stability optimum shape. la estabilidad deand la llama y su óptima flame stability and optimum shape. flame stability and optimum shape.forma. The swirler and other components of the nose ensure flame stability and optimum shape. Para obtener la mayor confiabilidad y un arranque sencillo, todos los taking awaydevaluable heating capacity. quemadores Astec sondryer meticulosamente sometidos a prueba antes RELIABLE FIRING RELIABLE FIRING MODELO de ser enviados. reliability and start-up ease, all Astec burners For For maximum maximumFIRING reliability and start-up ease, all Astec burners RELIABLE are thoroughly tested shipping. ESPECIFICACIONES DE LA COMBUSTIÓN are maximum thoroughly tested before before shipping. For reliability andEXCESO start-up CON BAJO DEease, AIRE all Astec burners are thoroughly tested Capacidadbefore shipping. Capacidad Aire de la atom. de aceite de secado Capacidad Potencia del nominal m3/min de agregado de aire del ventilador en kW nominal a 5% quemador interno en (con 20%LOW de EXCESS AIR SPECS LOW EXCESS AIR FIRING FIRING SPECS de humedad m3/min kW XSA) Fuego bajo Fuego alto (mtph) MODEL MODEL MODEL PT 150 PT PT150 150 150 PT PT PT100 100 100 PT 75PT2 PT PT75 75 75 MODEL PT 125 PT PT125 125 125100 PT 150 PT 100 PT PT 125 PT2 PT2 PT2 75 PT2 50 Rated Capacity Nominal Aggregate Burner Air Integral Oil Atomizing Rated Nominal Aggregate Burner Oil LOW EXCESS FIRING RatedCapacity Capacity Nominal Aggregate AIR BurnerAir Air Integral IntegralSPECS Oil Atomizing Atomizing Millions Drying Blower Air Millions of Drying Capacity Capacity Blower Air Requirement Millionsof of DryingCapacity Capacity Capacity Capacity Blower AirRequirement Requirement BTU/HR at 5% Moisture SCFH Horsepower SCFM 14641 314Burner 2.3 BTU/HR at 5% SCFH Horsepower SCFM BTU/HR at181 5%Moisture Moisture SCFHAir 30 Horsepower SCFM Rated Capacity Nominal Aggregate Integral 2.8 Oil Atomizing (with 20% Low Fire (with 20% XSA) High Fire (with 20%XSA) XSA) Low Fire High HighFire Fire Millions of Drying Capacity Capacity Blower Low Air Fire Requirement BTU/HR at 5% Moisture SCFH Horsepower SCFM (with 20% XSA) Low Fire High Fire 75 300 85 21961 272 75 300 tph tph 47211 mill. mill. 45 75 75 2.8100 100 2.4 85 75 100 100 29281 300 tph 1 mill. 75 400 tph 1.3 mill. 400 tph 6251.3 mill.56 75 75 363 100 125 125 36601 400 tph 500 500 tph tph 454 125 150 150 43922 500 tph 1.6 mill. 100 110 600 600 tph tph 94422 mill. mill. 93 125 125 3.5125 125 544 150 600 tph 1.3 mill. 1.6 1.6 mill. mill. 712 2 mill. 75 75 100 100 125 100 100 2.8100 85 80 80 2.3 100 110 110 80 80 80 2.8 125 The Phoenix Talon uses significantly less electric The Phoenix Talon uses significantly The Phoenix Talon uses mucho significantly less electric electric El Phoenix Talon consume menos less energía power burners due power than conventional burners due to the variable eléctrica queconventional los quemadores convencionales gracias power than than conventional burners due to to the the variable variable frequency drive used to control its combustion air frequency drive used to control its combustion air The Phoenix Talon significantly less electric al mando de frecuencia que utiliza para frequency drive useduses tovariable control its se combustion air blower and low body pressure. blower and low body pressure. controlar su ventilador de aire de combustión y la power burners due to the variable blowerthan and conventional low body pressure. baja presión de laused carrocería. frequency drive to control its combustion air blower and low body pressure. 2.3 80 90 90 2.5 90 $ERYHFRQGLWLRQVDUHVWDQGDUGDWÜ)DWVHDOHYHO6HHGHWDLOHGFDSDFLW\SHUIRUPDQFHVKHHWVIRUHDFKVL]H $ERYHFRQGLWLRQVDUHVWDQGDUGDWÜ)DWVHDOHYHO6HHGHWDLOHGFDSDFLW\SHUIRUPDQFHVKHHWVIRUHDFKVL]H $ERYHFRQGLWLRQVDUHVWDQGDUGDWÜ)DWVHDOHYHO6HHGHWDLOHGFDSDFLW\SHUIRUPDQFHVKHHWVIRUHDFKVL]H Las condiciones anteriores son estándares aFÁ 21RZVDQGSUHVVXUHV1RPLQDODJJUHJDWHGU\LQJFDSDFLW\EDVHGRQW\SLFDO °C del nivel del mar. Vea la capacidad detallada, las hojas de rendimiento de cada IRUPRUHLQIRUPDWLRQDQGVSHFLÀ IRUPRUHLQIRUPDWLRQDQGVSHFLÀ FÁ RZVDQGSUHVVXUHV1RPLQDODJJUHJDWHGU\LQJFDSDFLW\EDVHGRQW\SLFDO IRUPRUHLQIRUPDWLRQDQGVSHFLÀ FÁ H[KDXVWVWDFNWHPSHUDWXUHVRIÜ)%78/EP)VSHFLÀ FKHDWLQWKHDJJUHJDWH%XUQHUPD[LPXP tamaño para obtener más información y flujos yRZVDQGSUHVVXUHV1RPLQDODJJUHJDWHGU\LQJFDSDFLW\EDVHGRQW\SLFDO presiones específicas. La capacidad de secado del agregado nominal en base a las H[KDXVWVWDFNWHPSHUDWXUHVRIÜ)%78/EP)VSHFLÀ H[KDXVWVWDFNWHPSHUDWXUHVRIÜ)%78/EP)VSHFLÀFKHDWLQWKHDJJUHJDWH%XUQHUPD[LPXP FKHDWLQWKHDJJUHJDWH%XUQHUPD[LPXP GHVLJQFDSDFLW\LVRIUDWHGFDSDFLW\ temperaturas típicas del tubo de escape de 115.6° C, 0.2 cal/g °C de calor específico en el agregado. La capacidad máxima del GHVLJQFDSDFLW\LVRIUDWHGFDSDFLW\ GHVLJQFDSDFLW\LVRIUDWHGFDSDFLW\ 1DWXUDO*DV12[330&23301XPEHU)XHO2LO330&2330 $ERYHFRQGLWLRQVDUHVWDQGDUGDWÜ)DWVHDOHYHO6HHGHWDLOHGFDSDFLW\SHUIRUPDQFHVKHHWVIRUHDFKVL]H 1DWXUDO*DV12[330&23301XPEHU)XHO2LO330&2330 diseño del quemador es igual a su capacidad nominal. 1DWXUDO*DV12[330&23301XPEHU)XHO2LO330&2330 IRUPRUHLQIRUPDWLRQDQGVSHFLÀFÁRZVDQGSUHVVXUHV1RPLQDODJJUHJDWHGU\LQJFDSDFLW\EDVHGRQW\SLFDO H[KDXVWVWDFNWHPSHUDWXUHVRIÜ)%78/EP)VSHFLÀFKHDWLQWKHDJJUHJDWH%XUQHUPD[LPXP GHVLJQFDSDFLW\LVRIUDWHGFDSDFLW\ 1DWXUDO*DV12[330&23301XPEHU)XHO2LO330&2330 The The Phoenix Talon’s compact flame shape isis The Phoenix Phoenix Talon’s Talon’s compact compact flame flame shape shape is compatible with most drums without complicated compatible compatible with with most most drums drums without without complicated complicated flame adjustment. flame adjustment. The Phoenix Talon’s flame shape flame adjustment. La forma compacta de la compact llama del Phoenix Talon esis compatible withla most drums without complicated compatible con mayoría de los tambores sin ajuste flame adjustment. complicado de la llama. ASTEC ASTEC PHOENIX® FURY BURNER QUEMADORES PHOENIX® FURY A robust build and simple, accessible construction makessólida the Phoenix Furyyburner a great cost-effective Una fabricación y simple una construcción económica hacen choice. Compared otheralternativa open-fired excelente designs, the del quemador Phoenix Fury touna y rentable. achieves betterabierto, emissions and fuel-Fury logra ComparadoFury con burner otros diseños de fuego el quemador mejores emisiones y rendimiento al permitir efficiency by putting del 50%combustible more combustion airel paso de 50% más aire de combustión through the burner.a través del quemador. FURY ® LOW COST BAJO COSTO in the de aggregate El éxitoSuccess en la industria agregadosand o deHMA HMAindustries depende de la depends on profitability. The de Astec Fury rentabilidad. El quemador Phoenix Fury AstecPhoenix es la alternativa burner is the low cost alternative to more expensive de bajo costo frente a otros diseños más costosos totalmente de aire. total air designs. SIMPLICIDAD SIMPLICITY Simple construction maintenance easy. Su construcción simple hace makes que el burner mantenimiento del quemador sea sencillo. La construcción simple y económica quemador hace que sea The simple and accessibledelconstruction makes de fácilburner mantenimiento: su fabricación resistente mantiene maintenace easy: while it’s rugged buildlos costos de mantenimiento al mínimo. keeps maintenance costs to a minimum. EFFICIENCY EFICIENCIA swirling, high-energy air is es thelakey the El aire Rapidly rápidamente arremolinado y dinámico clavetopara Fury burner’s efficient combustion. The swirling air que el quemador Fury logre una combustión eficiente. Las paletas and flame are created by the fixed internal spin fijas con rotación interna, el soplador de alta presión y el extremo high-pressure blower, andarremolinado. high velocity de granvanes, velocidad generan la llama y el aire nose. FORMA COMPACTA LA LLAMA COMPACT FLAME DE SHAPE complicated adjustments. MEJORES EMISIONES BETTER EMISSIONS El quemador Fury de Astec está diseñado para colocar 50% más aire The Astec Fury burner is designed to put 50% more de combustión a través de quemador que otros diseños competitivos. combustion air through the burner than competiEsto significa más calidad en la combustión, mejores emisiones y tive designs. This means higher combustion quality, mayor eficiencia en todo el rango de combustión del quemador. better emissions, and higher efficiency combustion throughout the entire firing range of the burner. SIN AIRE COMPRIMIDO NO COMPRESSED El diseño de Astec de la boquilla de AIR combustible recubierta utiliza Thecombustión Astec designed pre-filming fuel nozzle el aire de del soplador de alta presión para utilizes atomizar the combustion airla from the high-pressure el combustible. Esto elimina necesidad de comprimir elblower aire en el to atomize This eliminates need for comquemador y ayuda afuel. incrementar la vida útilthe de la boquilla. pressed air at the burner, and helps increase nozzle life. CONFIABILIDAD Todos los quemadores también son sometidos a prueba antes RELIABILITY de salirEach de la fábrica Astecthoroughly para que tested puedanbefore comenzar burner is also leav-a funcionar lo más rápido posible en su instalación. Para obtener ing the Astec burner facility to make start-up at your la temperatura de fast encendido más confiable incluso facility as as possible. For the del mostaceite, reliable oil en condiciones frías y adversas, el quemador Fury cuenta conthe el light-off, even under cold and harsh conditions, sistemaFury de aplicación calor y aislamiento exclusivo de Astec. burner isdesupplied with Astec’s exclusive heat tracing and insulation system. The compact flame enables the Fury burner to work virtually all drum designs. La llamawith compacta permite que el quemador Fury trabaje con casi todos los diseños de tambor. BURNER FIRING SPECIFICATIONS 100PF 75 PF 75PF 50 PF 50MODELO MODEL PFPF 100 El quemador Phoenix Fury combustible o gasefficiently de una forma The Phoenix Furyquema burner cleanly and limpia yburns eficiente. Su llama compacta hace que sea compatible oil or gas. Its compact flame makes it con casi todos los diseños with de tambor sin ajustes complicados. compatible virtually all drum designs without ESPECIFICACIONES DEL QUEMADOR Nominal Rated Capacity Millions Capacidad of nominal en BTU/HR kW 50 14641 75 21961 Burner Integral Aggregate Capacidad Air Blower Drying de Capacity Potencia Horsepower secado de Capacidad Capacity SCFH del agregado at 5% de aire del ventilador nominal quemador Moisture interno en a 5% de m3/min kW humedad (mtph) 200 tph 181 300 tph 272 0.65 60 Mill. 195 45 1 Mill. 292 75 56 100 400 tph 1.3 Mill. 125 29281 363 389 93 Above conditions are standard 70˚F and sea level. See detailed capacity performance sheets for each size for more andla specific flows and Las condiciones anteriores son estándares a 21 °C delinformation nivel del mar. Vea pressures. Nominallasaggregate dryingde capacity based typical capacidad detallada, hojas de rendimiento cada tamaño paraon obtener más exhaust stack temperatures at 240˚F, 0.24 btu/Ibm F specificdeheat indel theagregado aggregate. información y flujos y presiones específicas. La capacidad secado nominal en base a las temperaturas típicas del tubo de escape de 115.6° C, 0.2 cal/g °C de calor específico en el agregado. La capacidad máxima del diseño del quemador es igual a su capacidad nominal. ASTEC ASTEC PHOENIX® PHANTOM QUEMADORES PHOENIX PHANTOM® Astec’s premium Ultra Low NOx Phoenix Phantom burner leads the pack El quemador Phoenix Phantom premium con nivel ultra bajo de NOx es el líder with the lowest available combustion and noise emissions (gaseous en quemadores gracias a la combustión y a las emisiones de ruido más bajas fuels only). The Phantom also achieves the highest electrical energy disponibles (sólo combustibles gaseosos). El quemador Phantom también alcanza la ciency with en innovations like speed drives. The Phantom offers máseffi alta eficiencia el consumo devariable energía eléctrica gracias a innovaciones como advanced technology the tecnología latest technological to y las los mandos de mixing velocidad variable.and Ofrece avanzadainnovations de mezclado deliver thetecnológicas absolute minimum gaseouspara emissions today. innovaciones más modernas poderavailable proporcionar las emisiones gaseosas mínimas más eficientes en la actualidad. 2.5M. WMS. 12-06 ADVANCED EMISSION REDUCTION ADVANCED EMISSION REDUCTION REDUCCIÓN AVANZADA DE LAS EMISIONES The Phoenix Phantom is the onlyREDUCTION burner available in the hot ADVANCED El Phoenix PhantomEMISSION es el único quemador disponible en la industria The Phoenix Phantom is the only burner available in the hot mix industry using most advanced technology The Phoenix Phantom iscaliente thethe only burner available in the más hot de laasphalt mezcla de asfalto en tecnología mix asphalt industry using the que mostimplementa advancedla technology to precisely and completely mix the air and gaseoso gaseous to avanzada para mezclar el airethe y el combustible enfuel forma mix asphalt industry using most advanced technology to precisely and completely mix the air and gaseous fuel to completa y precisa para poder alcanzar el método de bajo nivel de achieve an advanced low NOx COand method called to precisely and completely mix and the air gaseous fuellean to achieve an advanced NOx and CO method lean NOx y CO denominadolow combustible premezclado de called proporción burn premix. Phantom low employs multiple parallelcalled turbulent achieve an advanced NOxaand CO method lean pobre.premix. El quemador Phantom emplea mezclador de tubo de flujo burn Phantom employs a un multiple parallel turbulent tube mixer to achieve near perfect mixing of fuel and air. burn premix. Phantom employs a multiple parallel turbulent paralelo múltiple y turbulento lograr la mezcla de combustible tube mixer to achieve nearpara perfect mixing of fuel and air. y aire casi a la to perfección. tube mixer achieve near perfect mixing of fuel and air. PHANTOM PHANTOM PHANTOM ® ® ® RELIABLE FIRING & ADVANCED DESIGN RELIABLE FIRING & ADVANCED DESIGN The Phoenix Phantom is & thoroughly tested before leaving RELIABLE FIRING ADVANCED DESIGN COMBUSTIÓN CONFIABLE Y DISEÑO The Phoenix Phantom is thoroughly tested before leaving the factory ensure reliability and start-up ease. leaving The PhoenixtoPhantom is thoroughly tested before AVANZADO the factory to ensure reliability and start-up ease. Highly effiPhantom cient variable speed blower controls provide El Phoenix es meticulosamente aease. prueba antes de the factory to ensure reliability andsometido start-up Highly effi cient para variable speed blower controls provide salir de la fábrica garantizar confiabilidad y un arranque damper-less air flvariable ow control. Combustion air and fuel sencillo. Highly efficient speed blower controls provide damper-less air ventilador flow control. Combustion airde and fuel Los controles del de velocidad variable gran eficiencia fldamper-less ow meters can combined with Astec PLC/Computer air del flbe ow control. Combustion air Los and fuel brindan un control flujo de aire de menor registro. flujómetros flow meters can be combined with Astec PLC/Computer del Burner Controls the most precise and reliable flaire owdemeters can for be combined with Astec PLC/Computer combustión y combustible pueden combinarse con burner los controles Burner Controls for the most precise and reliable burner control available. del quemador por for PLC/computadora de Astec lograr el control Burner Controls the most precise and para reliable burner control available. más preciso y confiable disponible. control available. FIRING EFFICIENCY & COMPACT FLAME SIZE FIRING EFFICIENCY & COMPACT FLAME SIZE EFICIENCIA COMBUSTIÓN Y LLAMA When running inDE lean burn & mode, near perfect mixing SIZE of FIRING EFFICIENCY COMPACT FLAME When running in lean burn mode, near perfect mixing of COMPACTA air andrunning fuel before burning theperfect most compact When in lean burn produces mode, near mixing of air and elfuel before burning produces thepobre most está compact Cuando modo de combustible de proporción activado, la flair ame available. Theburning compact flame size to and fuel before produces the contributes most compact flmezcla ame available. compact size contributes de aire casiThe perfecta previaflaame la combustión produce to la llama effi ciency, ensuring all of the fuelsize is combusted without flmás ame available. Thethat compact flame contributes to compacta disponible. tamaño de la llama contribuye effi ciency, ensuring thatElall of thecompacto fuel is combusted without taking away valuable dryer heating like other low effi ciency, that all of the fuelcapacity isque combusted without a alcanzar laensuring mejor eficiencia, todo el combustible taking away valuable dryergarantizando heating capacity like other low se queme sin disminuir valiosa capacidad de calentamiento con emission methods thatladryer use flue gas recirculation orother waterlow taking away valuable heating capacity like emission methods thatotros usemétodos flue gas recirculation or water secador como lo hacen con bajos niveles de emisiones, injection emission methods. methods that use flue gas recirculation or water injection methods. que utilizan los métodos de recirculación de la emanación de gas o injection methods. de inyección de agua MODEL MODEL PP 150 150 PP 125 125 PP 100 100 PP 7575MODEL PPPP 150 PPPP 125 PPPP 100 PPPP 75 PP 75 MODELO PP 150 PP 125 PP 100 ESPECIFICACIONES COMBUSTIBLE PREMEZCLADO LEAN BURNDEL PREMIX FIRING SPECS DE PROPORCIÓN LEAN BURN PREMIX POBRE FIRING SPECS PREMIX FIRING Rated LEAN Capacity BURN Nominal Aggregate Burner Air SPECS Integral Capacidad de Capacidad nominal Capacidad Potencia del Rated Capacity Nominal Aggregate Burner Air Integral Millions of Drying Capacity Capacity Blower secado de agregado en kW de aire del Air ventilador interno Rated Capacity Nominal Aggregate Burner Integral Millions of Drying Capacity Capacity Blower BTU/HR at 5%aMoisture SCFH Horsepower nominal 5% de (con 20% de m3/min en kW Millions of XSA) Drying Capacity quemadorCapacity Blower BTU/HR athumedad 5% Moisture SCFH Horsepower (with 60% XSA) at 5% Moisture SCFH Horsepower (withBTU/HR 60% XSA) (with 60% XSA) 75 300 1.3 mill. 100 21961 272 tph 614 75 75 75 300 tph 300 tph 1.3 mill. 1.3 mill. 100 100 100 29281 100 100 400 tph 363 tph 400 400 tph 1.7 mill. 802 1.7 mill. 125 93 125 125 125 36601 125 125 500 tph 454 tph 500 500 tph 1,038 2.2 mill. 150 43922 150 150 600 tph 544 tph 600 600 tph 1,227 2.6 mill. 1.7 mill. 1.7 mill. 2.2 mill. 2.2 mill. 2.6 mill. 2.6 mill. 0.10 0.08 0.10 0.06 0.08 0.10 0.05 0.06 0.08 0.03 0.05 0.06 0.03 0.05 Gas Concentration Gas Concentration mixing: uniformly 0.03 green Gas Concentration Natural gas injection and Natural gas injection and mixing: uniformly green color indicates complete of air/gas. Inyección de gas natural ymixing mezclado: el color verde Natural gas injection mixing: uniformly green color indicates completeand mixing of air/gas. uniforme indica complete la mezclamixing completa de aire/gas. color indicates of air/gas. 1.75e+02 1.66e+02 1.75e+02 1.57e+02 1.66e+02 1.49e+02 1.75e+02 1.57e+02 1.40e+02 1.66e+02 1.49e+02 1.57e+02 1.57e+02 1.40e+02 1.31e+02 1.49e+02 1.57e+02 1.22e+02 1.40e+02 1.31e+02 1.14e+02 1.57e+02 1.22e+02 1.05e+02 1.31e+02 1.14e+02 9.61e+01 1.22e+02 1.05e+02 8.74e+01 1.14e+02 9.61e+01 7.87e+01 1.05e+02 8.74e+01 6.99e+01 9.61e+01 7.87e+01 6.12e+01 8.74e+01 6.99e+01 5.24e+01 7.87e+01 6.12e+01 4.37e+01 6.99e+01 5.24e+01 3.50e+01 6.12e+01 4.37e+01 2.62e+01 5.24e+01 3.50e+01 1.75e+01 4.37e+01 2.62e+01 8.74e+00 3.50e+01 1.75e+01 0.00e+00 2.62e+01 8.74e+00 1.75e+01 0.00e+00 8.74e+00 0.00e+00 Z X Z Y X Y ZX Path Lines Colored by Velocity Magnitude (ft/s) Y Lines Colored by Velocity Magnitude (ft/s) Path Velocity magnitude as airMagnitude and natural Path Linesincreases Colored by Velocity (ft/s) Velocity increases as aira medida and natural La de la velocidad aumenta que gasmagnitud mix. magnitude Velocity as air and natural gas mix. el aire y elmagnitude gas naturalincreases se mezclan. gas mix. 150 112 150 150 200 149 200 200 $ERYHFRQGLWLRQVDUHVWDQGDUGDWÜ)DWVHDOHYHO6HHGHWDLOHGFDSDFLW\SHUIRUPDQFHVKHHWVIRUHDFKVL]H Las condiciones anteriores son estándares aFÁ 21RZVDQGSUHVVXUHV1RPLQDODJJUHJDWHGU\LQJFDSDFLW\EDVHGRQW\SLFDO °C del nivel del mar. Vea la capacidad detallada, las hojas de rendimiento de cada IRUPRUHLQIRUPDWLRQDQGVSHFLÀ $ERYHFRQGLWLRQVDUHVWDQGDUGDWÜ)DWVHDOHYHO6HHGHWDLOHGFDSDFLW\SHUIRUPDQFHVKHHWVIRUHDFKVL]H tamaño para obtener más información y flujos y presiones específicas. La capacidad de secado del agregado nominal en base a las H[KDXVWVWDFNWHPSHUDWXUHVRIÜ)%78/EP)VSHFLÀ FKHDWLQWKHDJJUHJDWH%XUQHUPD[LPXP IRUPRUHLQIRUPDWLRQDQGVSHFLÀ FÁRZVDQGSUHVVXUHV1RPLQDODJJUHJDWHGU\LQJFDSDFLW\EDVHGRQW\SLFDO GHVLJQFDSDFLW\LVRIUDWHGFDSDFLW\ $ERYHFRQGLWLRQVDUHVWDQGDUGDWÜ)DWVHDOHYHO6HHGHWDLOHGFDSDFLW\SHUIRUPDQFHVKHHWVIRUHDFKVL]H temperaturas típicas del tubo de escape de 115.6° C, 0.2 cal/g °C de calor FKHDWLQWKHDJJUHJDWH%XUQHUPD[LPXP específico en el agregado. La capacidad máxima del H[KDXVWVWDFNWHPSHUDWXUHVRIÜ)%78/EP)VSHFLÀ 33012[330&2DWUHIHUHQFH IRUPRUHLQIRUPDWLRQDQGVSHFLÀ FÁRZVDQGSUHVVXUHV1RPLQDODJJUHJDWHGU\LQJFDSDFLW\EDVHGRQW\SLFDO diseño del quemador es 110% de la capacidad nominal. *Los números publicados se obtienen en ciertas condiciones, pero no está GHVLJQFDSDFLW\LVRIUDWHGFDSDFLW\ $GYHUWLVHGQXPEHUVDUHDFKLHYDEOHLQVRPHFRQGLWLRQVEXWQRWJXDUDQWHHG H[KDXVWVWDFNWHPSHUDWXUHVRIÜ)%78/EP)VSHFLÀ FKHDWLQWKHDJJUHJDWH%XUQHUPD[LPXP 33012[330&2DWUHIHUHQFH completamente garantizado. GHVLJQFDSDFLW\LVRIUDWHGFDSDFLW\ $GYHUWLVHGQXPEHUVDUHDFKLHYDEOHLQVRPHFRQGLWLRQVEXWQRWJXDUDQWHHG 33012[330&2DWUHIHUHQFH $GYHUWLVHGQXPEHUVDUHDFKLHYDEOHLQVRPHFRQGLWLRQVEXWQRWJXDUDQWHHG Thequemador premiumpremium PhoenixPhoenix Phantom is used where El Phantom se utiliza The premium Phantomconcern, is used where emissions limitsPhoenix arelasaemisiones driving (typically donde los límites de generan probThe premium Phoenix Phantom is used where emissions limits are a driving concern, (typically the Phantom is not supplied withnooptional oil nozzle lemas (comúnmente, el Phantom cuenta con una emissions are a driving concern, (typically the Phantom is notopcional supplied with optional oil nozzle boquilla de limits aceite porque su tecnología because its premium Ultra-Low emissions technology the Phantom is notfuel) supplied with optional oilsenozzle because its premium Ultra-Low emissions technology premium con niveles de emisiones ultra bajas applies to gaseous because premiumfuel) Ultra-Low applies gaseous aplica altoits combustible gaseoso). emissions technology applies to gaseous fuel) ASTEC ASTEC WHISPER JET® QUEMADORES WHISPER JET® The Whisper Jet delivers unmatched reliability and hassle-free maintenance. The Whisper Jet El quemador Whisper Jet brinda una confiabilidad sin igual y fácil cleanly and efficiently burns oil or gas and mantenimiento. El Whisper Jet quema combustible o gas de una forma its compact flame makes it compatible with limpia y eficiente, y su llama compacta hace que sea compatible con virtually all drum designs without complicated casi todos los diseños de tambores sin ajustes complicados. adjustments. 2.5M. WMS. 12-06 TROUBLE-FREE MAINTENANCE & OPERATION Maintenance and downtime are virtually eliminated by TROUBLE-FREE MAINTENANCE & OPERATION MANTENIMIENTO Y FUNCIONAMIENTO the careful design ofMAINTENANCE the Whisper Jet burner. Whisper TROUBLE-FREE & The OPERATION Maintenance and downtime are virtually eliminated by SIN PROBLEMAS Jet burner usesand thedowntime highest quality, field-proven components. Maintenance are virtually eliminated by El mantenimiento y tiempo inactividad desaparecen the careful design ofMAINTENANCE thedeWhisper Jetprácticamente burner. The Whisper TROUBLE-FREE & OPERATION Each burner is also before leaving the Astec the careful design offully the tested Whisper Jet burner. gracias al diseño cuidadoso del quemador WhisperThe Jet. Whisper El Whisper Jet burner usesand thedowntime highest quality, field-proven components. Maintenance are virtually eliminated by burner factory to start-up your facility as fast as utiliza los componentes dequality, másatalta calidad y de rendimiento Jet burner uses themake highest field-proven components. Each burnerdesign is alsooflos fully tested before leaving thesometidos Astec a the careful thequemadores Whisper Jettambién burner. The Whisper comprobado. Todos son possible. For isthe most reliable light-off, eventhe under Each burner also fully tested oil before leaving Asteccold burner factory to start-up at your facility as fast as Jet burner uses themake highest quality, fipara eld-proven components. prueba antes de salir de la fábrica Astec que puedan comenzar and harsh conditions, Whisper Jet isfacility supplied withas burner factory to makethe start-up at your as fast a funcionar lo más rápido posible en su instalación. Para obtener possible. Foristhe most reliable light-off, eventhe under Each burner also fully tested oil before leaving Asteccold Astec’s exclusive heat tracing and insulation system. possible. For the most reliable oil light-off, even under cold la temperatura de encendido más confiable del aceite, incluso en and harsh conditions, Whisper Jet isfacility supplied with burner factory to makethe start-up at your as fast as condiciones y adversas, Whisper Jet cuenta con el with sistema de and harsh frías conditions, the elWhisper is supplied Astec’s exclusive heat tracing and insulation system. possible. Forcalor the ymost reliable oil light-off, under cold LOW COMBUSTION AND NOISEeven EMISSIONS aplicación de aislamiento. Astec’s exclusive heat tracing and insulation system. and harsh conditions, the Whisper Jet technology is supplied with The Whisper Jet uses unique patented to burn LOW COMBUSTION AND NOISE EMISSIONS Astec’s exclusive heat tracing and insulation system. cleanly and efficiently. True AND to Y its name, the Whisper Jet is LOW COMBUSTION NOISE EMISSIONS BAJA COMBUSTIÓN EMISIONES The Whisper Jet uses unique patented technology toDE burn designed andJet equipped to reduce burner noise over The Whisper uses unique patented technology to burn RUIDOS cleanly and efficiently. True AND to its name, the Whisper Jet is LOW COMBUSTION NOISE EMISSIONS competitive burners. El quemador Jet emplea exclusivathe tecnología patentada cleanly andWhisper efficiently. True touna its name, Whisper Jet is designed and equipped to reduce burner noise over The uses limpia unique patented to burn para Whisper quemar deJet manera eficiente. Fieltechnology a sunoise nombre, el Whisper designed and equipped to yreduce burner over competitive cleanly and burners. effi ciently. Truepara to its name, the Whisper Jet está diseñado y equipado reducir el ruido generadoJet poris el EFFICIENT COMBUSTION competitive burners. quemadorswirling de unaequipped forma los key de noise latocompetencia. designed and toeficiente reduce Rapidly high más energy air que is burner the theover Whisper EFFICIENT COMBUSTION competitive burners. Jet’s efficient combustion. The swirling air and flame are EFFICIENT COMBUSTION Rapidly swirling high EFICIENTE energy air is the key to the Whisper COMBUSTIÓN created by the fixed andtothe Rapidly swirling highinternal energy spin air isvanes the key thepatented Whisper Jet’s cient combustion. The yswirling flame El aireeffi rápidamente arremolinado dinámicoair es and la clave paraare que el EFFICIENT COMBUSTION castellated ring, andThe nozzle design. Jet’s efficientnose, combustion. swirling air and flame are Whisper Jet logre una combustión eficiente. El aire arremolinado y la created by the fixed andtothe Rapidly swirling highinternal energy spin air isvanes the key thepatented Whisper created by the fi xed internal spin vanes and the patented llama se generan por las and paletas fijas con rotación interna y por el castellated ring, nozzle design. Jet’s efficientnose, combustion. The swirling air and flame are diseño encastillado la punta, anillo y boquilla. castellated nose, patentado ring, anddenozzle design. created by the fixed internal spin vanes and the patented castellated nose, ring, and nozzle ESPECIFICACIONES DE LA design. COMBUSTIÓN ® ® ® ® Whisper Jet’s compact flame shape eliminates drum La forma compacta de la llama del Whisper Jet evita overheating and does not require complicated flame el recalentamiento del tambor y no se deben realizar shape adjustments for best efficiency. Whisper Jet’s compact flamecombustion shape eliminates drum ajustes complicados respecto de la llama para lograr Whisper Jet’s compact flame shape eliminates drum overheating and does not require complicated flame una mejor eficiencia de combustión. overheating and does complicated flame shape adjustments for not bestrequire combustion efficiency. shape adjustments for best combustion efficiency. Whisper Jet’s compact flame shape eliminates drum overheating and does not require complicated flame shape adjustments for best combustion efficiency. CON BAJO EXCESO DE AIRE WJ 150 WJ WJ 150 125 WJ WJ 150 WJ 125 100 WJ WJ 125 WJ 100 75 WJ WJ 100 WJ 757550 WJ WJ 75 50 5050 MODEL MODEL MODEL WJ 150 WJ 125 WJ 100 WJ WJ MODEL WJ 150 WJ 125 WJ 100 WJ 7550WJ WJ MODELO Capacidad LOW EXCESS AIR FIRING Aire SPECS Capacidad de la atom. de aceite de secado Capacidad Potencia del nominal m3/min de agregado de aire del ventilador kW Rateden Capacity Nominal Aggregate Burner Air Integral Oil Atomizing nominal a 5% quemador interno en LOW EXCESS AIR FIRING SPECS (con 20%ofde Millions Capacity Capacity Air Requirement deDrying humedad m3/min kW Blower SPECS LOW EXCESS AIR FIRING XSA) Fuego bajo SCFM Fuego alto BTU/HR at(mtph) 5% Moisture SCFH Horsepower Rated Capacity Nominal Aggregate Burner Air Integral Oil Atomizing (with 20% XSA) Nominal Aggregate Burner Air Integral Low High Fire Rated Capacity OilFire Atomizing Millions of Drying Capacity AIR Capacity Blower SPECS Air Requirement LOW EXCESS FIRING Millions of Drying Capacity Capacity Blower Air Requirement BTU/HR at 5% Moisture SCFH Horsepower SCFM 14641 307 SCFH 45 1.4 1.6 Fire BTU/HR at181 5% Moisture Horsepower SCFM (with XSA) Nominal Low High 50 200 tph 650,000 50 80 55 Rated20% Capacity Aggregate Burner Air Integral OilFire Atomizing (with 20% XSA) Low Fire High Fire Millions of Drying Capacity Capacity Blower Air Requirement BTU/HR at 200 5% Moisture SCFH Horsepower 50 tph 650,000 50 80 SCFM 55 (with21961 20% Low 1.6 50 XSA) 272 200 tph 472650,00056 50 2.1 80Fire High 55Fire 75 300 tph 50 75 29281 75 100 75 100 1 mill. 75 90 55 200 tph 650,000 300 tph 1 mill. 363 75 300 tph tph 6141.3 1 mill. 400 mill. 50 80 75 90 75 2.8 90 100 90 55 55 1.6 55 55 300 400 tph tph 1 mill. 1.3 mill. 75 90 100 90 3.5 100 90 125 120 2.0 55 70 36601 100 125 454 400 500 tph tph 7551.3 1.6 mill. mill.93 125 43922 100 125 150 500 tph 9441.6 mill.112 544 400 500 tph tph 600 tph 1.3 1.6 mill. mill. 2 mill. 100 90 125 120 125 4.2 120 150 140 125 150 150 500 tph 600 tph 600 tph 1.6 mill. 2 mill. 2 mill. 125 150 150 120 140 140 55 70 90 70 2.5 70 90 90 $ERYHFRQGLWLRQVDUHVWDQGDUGDWÜ)DWVHDOHYHO6HHGHWDLOHGFDSDFLW\SHUIRUPDQFHVKHHWVIRUHDFKVL]H IRUPRUHLQIRUPDWLRQDQGVSHFLÀFÁRZVDQGSUHVVXUHV1RPLQDODJJUHJDWHGU\LQJFDSDFLW\EDVHGRQW\SLFDO $ERYHFRQGLWLRQVDUHVWDQGDUGDWÜ)DWVHDOHYHO6HHGHWDLOHGFDSDFLW\SHUIRUPDQFHVKHHWVIRUHDFKVL]H H[KDXVWVWDFNWHPSHUDWXUHVRIÜ)%78/EP)VSHFLÀ FKHDWLQWKHDJJUHJDWH%XUQHUPD[LPXP IRUPRUHLQIRUPDWLRQDQGVSHFLÀ FÁRZVDQGSUHVVXUHV1RPLQDODJJUHJDWHGU\LQJFDSDFLW\EDVHGRQW\SLFDO GHVLJQFDSDFLW\LVRIUDWHGFDSDFLW\ H[KDXVWVWDFNWHPSHUDWXUHVRIÜ)%78/EP)VSHFLÀ FKHDWLQWKHDJJUHJDWH%XUQHUPD[LPXP GHVLJQFDSDFLW\LVRIUDWHGFDSDFLW\ $ERYHFRQGLWLRQVDUHVWDQGDUGDWÜ)DWVHDOHYHO6HHGHWDLOHGFDSDFLW\SHUIRUPDQFHVKHHWVIRUHDFKVL]H IRUPRUHLQIRUPDWLRQDQGVSHFLÀFÁRZVDQGSUHVVXUHV1RPLQDODJJUHJDWHGU\LQJFDSDFLW\EDVHGRQW\SLFDO H[KDXVWVWDFNWHPSHUDWXUHVRIÜ)%78/EP)VSHFLÀFKHDWLQWKHDJJUHJDWH%XUQHUPD[LPXP GHVLJQFDSDFLW\LVRIUDWHGFDSDFLW\ 600 tph 2 mill. 150 140 The heavy-duty main fan damper is constructed to The heavy-duty fan damper is constructed to provide years of main trouble-free Hay un regulador resistente deloperation. ventilador principal provide years of trouble-free operation. que brinda años de funcionamiento sin problemas. The heavy-duty main fan damper is constructed to provide years of trouble-free operation. 55 55 Las condiciones anteriores son estándares a 21 °C del nivel del mar. Vea la capacidad detallada, las hojas de rendimiento de cada $ERYHFRQGLWLRQVDUHVWDQGDUGDWÜ)DWVHDOHYHO6HHGHWDLOHGFDSDFLW\SHUIRUPDQFHVKHHWVIRUHDFKVL]H tamaño para obtener más información y flujos y presiones específicas. La capacidad de secado del agregado nominal en base a las IRUPRUHLQIRUPDWLRQDQGVSHFLÀFÁRZVDQGSUHVVXUHV1RPLQDODJJUHJDWHGU\LQJFDSDFLW\EDVHGRQW\SLFDO temperaturas típicas del tubo de escape de 115.6° C, 0.2 cal/g °C de calor específico en el agregado. La capacidad máxima del H[KDXVWVWDFNWHPSHUDWXUHVRIÜ)%78/EP)VSHFLÀ FKHDWLQWKHDJJUHJDWH%XUQHUPD[LPXP diseño del quemador es 110% de la capacidad nominal. GHVLJQFDSDFLW\LVRIUDWHGFDSDFLW\ 150 The heavy-duty main fan damper is constructed to provide years of trouble-free operation. 90 Whisper Jet’s patented design promotes more rapid mixing and combustion. Whisper Jet’s patented design promotes more rapid Whisper Jet’s patented design promotes more rapid mixing and combustion. mixing and combustion. Whisper patented design promotes moremezrapid El diseño Jet’s patentado del Whisper Jet promueve mixingy and combustion. clado combustión más rápidos. 2.5M. WMS. 12-06

© Copyright 2026