on 20th March, 2015 - National Institute of Pharmaceutical

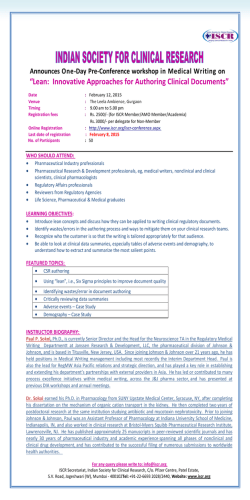

SPEAKERS Eminent personalities from academia, regulatory and highly experienced personnel from pharmaceutical industry shall deliver the lectures. A panel discussion on queries from participants shall also be held. REGISTRATION FEE Rs 3000 /- per delegate, Rs 2000/- for members registered with SMPIC, NIPER and Rs 800/- for students. The fee includes course material in the form of CD, lunch, refreshments, tea /coffee and excludes accommodation charges. About SMPIC SMALL AND MEDIUM PHARMACEUTICAL INDUSTRY CENTRE Department of Pharmaceuticals, Government of India, announced the setting up of a dedicated centre for Small and Medium Pharmaceutical Industries (SMPIs) at Pharmaceutical Advisory Forum (PAF) on 23rd April 2008. This Centre called as SMPIC, offers practical trainings on analytical instruments and conducts seminars on issues of Pr ocess Valida tion and Equipment Process alidation Qualif ica tion: A Risk Based Appr oac h Qualifica ication: pproac oach relevance to the Pharma industry like GLP, GMP & regulatory affairs. All these activities have been designed in consultation with SMPIs. This dedicated centre aims at creating synergy between industry and academia. NIPER has successfully conducted 53 training programs On-site Registration The on-site registration desk will be open on the day of seminar from 8.30 to 10.00 am. An additional fee of Rs 500/- will be charged for onsite registration. under the World Bank sponsored “Capacity Building Project” in the years 2004 to 2008. These were meant for the technical staff from government testing laboratories, regulatory bodies, private testing laboratories and analytical as well as production staff from SMPIs. How to reach NIPER, S.A.S. Nagar (Mohali) 20th March, 2015 NIPER, S.A.S. Nagar (Mohali) is situated near Chandigarh, that is well connected by air, rail and road. NIPER is about 18 km from Chandigarh Airport, 14 km from Chandigarh Railways Station, 10 km from ISBT, Sector-17, Chandigarh and 5 km from ISBT, Sector 43, Chandigarh. National Institute of Pharmaceutical Education and Research (NIPER) Sector 67, Near PCA Stadium, S.A.S. Nagar - 160 062, Punjab (Block G, Room no. 105) Phone : 0172-2292032, Fax : 0172-2214692 Email : [email protected] Equipment Qualification (EQ): Qualification of equipment is TOPIC OF SEMINAR an integral part of validation strategy. It provides documented SEMINAR ON evidence that the equipment has been installed as per PROCESS VALIDATION AND EQUIPMENT QUALIFICATION : A RISK BASED APPROACH specifications and will attain and maintain critical process parameters repeatedly and reliably. EQ has 3 main components like installation, operational and performance qualification. The Process Validation and Equipment Qualification: A Risk Based Approach Process Validation: Validation involves establishing documented state of EQ practices in the pharmaceutical industry is evolving evidence demonstrating that a specific process will consistently and is subject to much variation. EQ needs to be performed on produce a product meeting its pre-determined specifications and equipment used in laboratories and manufacturing. Through quality attributes. By validating the process, applications and risk assessment, impact of equipment on the quality of product equipment, it is guaranteed that the pharmaceutical products meet can be evaluated and the critical components of equipment/ quality demands and comply with regulations. The validation system can be identified. This approach assures that the Name Prof./Dr./Mr./Ms ............................................... validation activities are performed in a structured and GMP Designation ............................................................... procedure involves a series of activities taking place over the lifecycle of the product and process. A properly designed system will provide compliant manner according to the current regulations. 20th March, 2015 SMALL AND MEDIUM PHARMACEUTICAL INDUSTRY CENTRE National Institute of Pharmaceutical Education and Research (NIPER) Sector-67, Near PCA Stadium, S.A.S. Nagar-160062. (Punjab) Phone: 0172-2292032, Fax: 0172-2214692, email:[email protected] Registration Form Institute/Organization ................................................ a high degree of assurance that every step, process and change has This seminar shall focus on validation risk assessment activities been properly evaluated before its implementation. of both process and equipment. Different stages of process Over the recent past, pharmaceutical companies have begun moving validation like process design, Quality by design (QbD) and Address ..................................................................... continued process verification along with equipment validation .................................................................................. from the classic, validation strategy to a more targeted methodology based on risk. The evaluation of different risks is assessed by preparing a risk assessment chart through application of a process shall be discussed. The seminar is intended for the personnel .................................................................................. .................................................................................. from the industry and researchers within the academic community. Mobile No. ................................................................. failure mode, effects and criticality analysis. A risk-based approach to process validation helps to identify crucial control parameters that The following are some of the topics that shall be deliberated in E-mail ........................................................................ the seminar: Amount Paid for Registration .................................... different risks on product quality. 1. Process Validation: A Risk based approach DD No. & Date .......................................................... US FDA also encourages the use of modern pharmaceutical 2. QbD in manufacturing of APIs development concepts, quality risk management and quality systems 3. QbD in manufacturing of dosage forms at all stages of the manufacturing process. A risk assessment must 4. Instrumentation and Validation: A risk based approach be performed for all validations as it determines the validation 5. Aspects of Cleaning Validation affect product quality and provides a consistent method for evaluating REGISTRATION FEE Delegates Rs. 3000/- SMPIC Members Rs. 2000/- *Students Rs. 800/- parameters of the overall equipment or system and the required The last date for Registration is 16th March, 2015 functions. An extra Rs. 500/- for on-site Registration *Students are required to attach id Proof DD in favour of Director, NIPER, Payable at Mohali should be sent along with dully filled form.

© Copyright 2026