Please feel free to pass on to your colleagues who wish to register

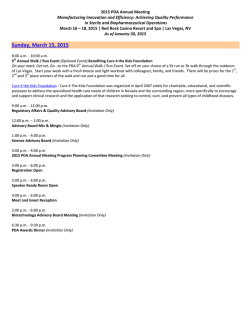

AGENDA AT A GLANCE DAY 1: FEBRUARY 10TH, 2015 9:30 – 10:00 TRACK A: Disruptive Innovation in Design of Medical Devices TRACK B: Managing Risk, Quality and Validation TRACK C: Speed to Market, Scale Up & Post Market Compliance 10:00 – 11:45 Designing Devices Towards Consumerization, Wireless Capabilities and Wearable Technology 1:00 – 2:30 Integrating Building Robust Advanced Sensor Risk Management Technology and Part 1 Power Management into your Device Design 2:45– 4:00 KEYNOTE ADDRESS Computers we can wear Creating and Implementing a Fully Compliant CAPA System Integrating your Medical Device into an Interconnected Wireless Ecosystem DAY 2: FEBRUARY 11TH, 2015 TRACK A: Disruptive Innovation in Design of Medical Devices TRACK B: Managing Risk, Quality and Validation TRACK C: Speed to Market, Scale Up & Post Market Compliance KEYNOTE ADDRESS Personalizing Surgery: 3D Printing and The Digital Thread DAY 3: FEBRUARY 12TH, 2015 TRACK A: Disruptive Innovation in Design of Medical Devices TRACK B: Managing Risk, Quality and Validation TRACK C: Speed to Market, Scale Up & Post Market Compliance KEYNOTE ADDRESS The Hackers Guide to the Galaxy Accelerating Speed to Market through Effective Prototyping and 3D Printing IDEO DESIGN WORKSHOP PART 1: Design research and inspiration How to Audit Proof Financing, Funding your Processes and Start-Ups and Effectively Prepare for an Inspection Improving User Experience and Usability Engineering Overhauling your Process Validation Part 1 How to Avoid Product Warning Letters and Recalls 3D Printing Materials Guide For Medical Devices IDEO DESIGN WORKSHOP PART 2: Ideation and prototyping Improving your Supplier Quality Strategies for Successful ScaleUp from Design to Manufacturing Designing for Better: Hospital Collaboration, Usability and Design Control Overhauling your Process Validation Part 2 Regulations for the Engineer: Aiming for First Time Submission Approval IDEO DESIGN WORKSHOP PART 3: Innovation thought leadership round table discussion Effectively Implementing a Quality Management System Lean Manufacturing: Beyond the Basics Practical Applications of Design Control Complying with UDI: What’s in Biocompatibility store for 2015 and Testing Standards beyond? and Guidance to get your Product to Market Faster Building Robust Addressing the Risk Management Regulatory and Part 2 Legal Challenges of 3D Printing Please feel free to pass on to your colleagues who wish to register! http://mdmwest.mddionline.com/conferencesseminars DAY ONE – TUESDAY, FEBRUARY 10th TRACK A: Disruptive Innovation in Design of Medical Devices TRACK B: Managing Risk, Quality and Validation TRACK C: Speed to Market, Scale Up & Post Market Compliance THE NEW WIRELESS FRONTIER: Innovations in Wireless Capabilities, Interoperability, and Sensor Technologies in Medical Devices REFINING YOUR RISK MANAGEMENT AND CAPA PROCEDURES ENTER THE 3D ERA: A New Dawn in Medical Device Design & Manufacturing CHAIR: Liam Pender, Ph.D., President & Chief Executive Officer, EGRET TECHNOLOGIES CHAIR: Geoff Hutchins, Chief Operations Officer, REGULATORY COMPLIANCE ASSOCIATES CHAIR: Donovan Weber, Chief Operating Officer, FORECAST3D 9:30AM – 10:00AM KEYNOTE ADDRESS Computers we can wear Babak Parviz, Ph.D., Vice President, Amazon | Former Google[x] Director 10:00AM – 11:45AM This industry juggernaut, creator of Google Glass and Google Contact Lens, will open the conference with a look into the current and future wearable technologies taking hold of the medical device and healthcare industries. Designing Devices Towards Creating and Implementing a Fully Compliant Accelerating Speed to Market through Consumerization, Wireless Capabilities and CAPA System Effective Prototyping and 3D Printing Wearable Technology 10:00 – 10:30 Designing for simplicity – Making products customers will love to buy Examples of where a simple design can be disruptive Examining current devices that apply the disruptive innovation principles Determining how much the current regulatory landscape disrupts disruptive innovation Exploring how to break the mold with a simpler next generation device Sridhar Iyengar, Co-Founder and Chief Technology Officer, MISFIT WEARABLES 10:00 – 10:30 Avoiding and responding to a CAPA specific warning letter Corrective and preventative action deficiencies have accounted for an increasing number of warning letters. Some may argue that CAPA discrepancies are overtaking 510k/ PMA submission regulatory headaches. This interactive presentation will help you effectively respond to a warning letter and help you avoid any future CAPA associated warning letters. Jay Jariwala, Quality System Specialist, Regulatory Compliance Officer, Office of Compliance, FDA 10:30 – 11:15 Wireless medical device design considerations for reimbursement, security and data management Will the “wireless” distinction in medical devices mean anything in 5 years or will it just be ubiquitous and table stakes? What will the wireless landscape look like in 10:30 – 11:15 CAPA gap analysis: Tell me something I don’t know about CAPA! This concentrated but intensive workshop will help you identify the most common CAPA shortfalls and eliminate your chance of receiving a CAPA associated warning letter. Uncovering the usual CAPA tripwires 10:00 – 10:30 Bringing life to your functional prototypes through 3D printing Insightful real life industry case studies demonstrating how 3D printing prototyping can cultivate innovation Evaluating the cost implications of 3D printing prototypes versus traditional methods Overcoming design challenges by utilizing additive manufacturing Justin Conway, Product Development Engineer, Orchid Orthopedic Solutions 10:30 – 11:15 PANEL DISCUSSION Integrating 3D printing into your established processes Over the last 12 months, most medical device companies have dipped their toe cautiously in the 3D printing pool. Going into 2015, companies are getting ready/are already integrating 3D printing capabilities into their processes. This panel Please feel free to pass on to your colleagues who wish to register! http://mdmwest.mddionline.com/conferencesseminars 5 years? Most devices are standalone these days and are reimbursed based on medical necessity or protocols. Will that be the same in the next few years or will device connectivity with EHRs change the reimbursement landscape? What is ONC and the FDA likely to require in terms of cybersecurity and what will that mean to medical device designs? Assuming big data and analytics progress continues unabated, what changes to device designs are required for improved data capture and management? Shahid N. Shah, Chief Executive Officer, Netspective Communications | Influential Blogger, HealthcareGuy.com - Steve Abrahamson, Director, Product Security Engineering, GE Healthcare Melissa Masters, RAC, Director of Electrical Software and Systems Engineering, Battelle Memorial Institute 11:15 – 11:45 Remote patient monitoring devices for the Aging Population and for Chronic Diseases: The good, the great and the exceptional! Gain real-life insights from three leading remote patient monitoring manufacturers and one medical design innovation consultancy giving detailed case studies on how they overcame design and engineering challenges for their remote patient monitoring devices for the aging population and chronic diseases. David Albert, M.D., Founder & Chief Medical Officer, AliveCor Brian Russell, Vice President Business Development Wireless, Respiratory and Monitoring Solutions, Covidien - Best practices in managing CAPA investigations Reviewing and correcting a non-conformity Verifying CAPA implementation and validating CAPA effectiveness How to apply risk management in the CAPA process Writing appropriate recurrence control and preventative action plans Diane Kulisek, Director Quality & Performance Improvement, Bruin Biometrics 11:15 – 11:45 PANEL DISCUSSION Rebooting your CAPA An esteemed panel of CAPA experts will share their best practices and lessons learned on implementing a successful CAPA system Implementing a compliant CAPA system that brings business value Aligning regulatory requirements with the GHTF CAPA guidance Discussing performance of CAPA investigational tools currently available Kevin Posey, Executive Quality/Regulatory Consultant, MAETRICS brings together a wealth of knowledge discussing the vital checkpoints of integrating 3D printing into your departments design and/or manufacturing methods Discussing where the medical device industry is now and where is it heading How to successfully collaborate with 3D printer vendors and material suppliers Converting 3D printing into business value Are you solving a clinical problem by 3D printing your product or device? Tyler Reid, Manufacturing Application Manager, GoEngineer Dave Flynn, Senior Business Development Manager, Materialise Justin Conway, Product Development Engineer, Orchid Orthopedic Solutions Ross Tsukashima, Engineering Director, Revision Optics Eric Utley, Additive Manufacturing Application Specialist, PROTO LABS 11:15 – 11:45 Using 3D printing for complex, high volume medical devices Marcelo Trevino, Senior Regulatory Compliance Exploring the major obstacles for the Manager, Medtronic medical device industry when integrating 3D printing into the development and Diane Kulisek, Director Quality & Performance, manufacturing life cycles Bruin Biometrics Evaluating the potential to streamline and Andrew Harrison, Vice President & General accelerate your concept to market time line Counsel, Regulatory Compliance Associates How will 3D printing impact your manufacturing bottom line? Determining the opportunities of using 3D printing for tooling and production when manufacturing medical devices Naomi Murray, Senior Manager, Additive Manufacturing, Stryker James Moon, Chief Technology Officer, Sotera Wireless Craig Scherer, Co-Founder & Senior Partner Insight Product Development Please feel free to pass on to your colleagues who wish to register! http://mdmwest.mddionline.com/conferencesseminars 1:00PM – 2:30PM Integrating Advanced Sensor Technology and Power Management into your Device Design Building Robust Risk Management Part 1 3D Printing Materials Guide For Medical Devices 1:00 – 1:40 Better, Faster, Stronger: Advances in new intelligent feedback systems and sensor technology and how to practically build this into your design plans Keeping up with technology upgrades and continuous product innovations in sensors to maximize their current and future capabilities Exploring soft sensors, self-calibration and wireless communication for monitoring and control applications Practical issues behind incorporating multiple sensors into medical devices New applications in pressure sensor technology, new semiconductor chip and low power sensor technologies Saeed Azimi, CEO & President, Dynosense 1:00 – 1:40 1:00 – 1:40 Updating your risk management protocol Material developments for 3D printing: From when using a new material biocompatible polymers to metals Overcoming the risk management Exploring the various materials currently challenges of evaluating and implementing available for 3D printed medical devices new materials within your medical device Discovering the range of available materials and finishes for single or multi-material use Determining if and when you need to change your risk analysis protocol for a new Addressing sterilization testing and material longevity concerns with new materials What new materials have been added to Reducing costs using new materials in the RoHS? rapid prototyping process Kevin Posey, Executive Quality/Regulatory Mobilizing new materials straight into Consultant, MAETRICS production Scott Hollister, Ph.D., Professor, Biomedical 1:40 - 2:00 Engineering, Associate Professor, Surgery, Refining software risk management when Professor, Mechanical Engineering, University designing your medical device of Michigan How to successfully embed your software risk management into your overall risk 1:40 – 2:00 1:40 - 2:00 management practice Development of an advanced 3D printed Use of miniaturized implantable devices for Developing your software with international scaffold for skeletal reconstruction patient empowered health care regulations in mind OPM manufactures FDA cleared PEKK Focusing on current and future implants using a 3D printing technique Best practices in preparing documentation miniaturization challenges with batteries and for medical device software 3D printed PEKK suitable for load bearing battery-pored medical devices applications (VBR) What software process improvement risk Detailing new developments in rechargeable management model is best for your device? Ability to manufacture implantable devices and primary cell systems to enable with complex geometries is driving Best practices in documenting risk increased longevity management innovation for the next generation of Assuring that your battery meets the unique devices Combining results from various risk requirements for its application whilst Severine Zygmont, Co-Founder, Oxford analysis tools such as FMEA, FTA, etc. performing reliably and safety Performance Materials Seyed Khorashahi, Director, Software Todd M. Zielinski, Ph.D., Senior Principal Engineering, Covidien Scientist, MEDTRONIC 2:00 – 2:30 Please feel free to pass on to your colleagues who wish to register! http://mdmwest.mddionline.com/conferencesseminars People Power: biomechanical energy harvesting for portable devices How much power is available to from the human body? What can be powered with human energy harvesting? What is the state-of-the-art in biomechanical energy harvesting? Max Donelan, Chief Scientific Officer, Bionic Power | Associate Professor, Department of Biomedical Physiology & Kinesiology, Simon Fraser University 2:00 – 2:30 ISO 9001 2015 update: The major changes heightened towards risk Managing the transition when the new standard is published in 2015 Discussing the new requirements for review, documentation updates and risk management Analyzing outcomes as a result of risk management changes Exploring the more risk-driven approach and actions to address risk Walt Murray, Director of Quality & Compliance Services, MASTERCONTROL 2:00 – 2:30 The realities, myths and future potential of bioprinting Latest in organ printing technologies and applications in tissue engineering and regenerative medicine Uncovering the limitations and challenges of this technology Detailing breakthroughs in printing human stem cells Practicalities of taking a quantum leap into the commercial arena Ibrahim T. Ozbolat, Ph.D., Assistant Professor, Mechanical & Industrial Engineering Department, The University of Iowa Please feel free to pass on to your colleagues who wish to register! http://mdmwest.mddionline.com/conferencesseminars 2:45PM – 4:00PM Integrating your Medical Device into an Interconnected Wireless Ecosystem Building Robust Risk Management Part 2 Addressing the Regulatory and Legal Challenges of 3D Printing 2:45 – 3:30 Panel Debate: Future medical device communication: Which platform is best for different device portfolios and will a single platform emerge? Addressing the connectivity conundrum WiFi, Bluetooth or Cellular for different types of devices? Debating the best approach to incorporate cloud – needs a bit more detail Discussing if and how Bluetooth and 802.11 Wi-Fi can co-exist Understanding what are the most optimal RFs for short range and long range devices Tips for overcoming the security concerns of cloud storage and overall data management MODERATOR: Andrew Malcolmson, Director, Integrated Patient Intelligence (Vital Sync), Covidien 2:45 – 4:00 ROUND TABLE Risk Control of ISO 14971 A distinguished group of risk management experts will explore why the industry continues to struggle with ISO 14971, and will provide complete take away solutions to overcome the most common challenges with this standard through practical case study projects. Detailing how to establish and maintain a more robust risk management program Going beyond Failure Modes and Effects Analysis – Exploring the most effective risk assessment methods Discussing the updated change of the use of risk control of ISO 14971 amendment 2 David Vogel, Ph.D., Founder and President, Intertech Engineering Associates 2:45 – 3:30 PANEL DISCUSSION The FDA and 3D printing waltz Discussing the current and future role of the FDA in additive manufacturing regulations Detailing the types of medical devices that the FDA have cleared/approved to date Addressing the potential technical concerns with 3D printing including mechanical properties, biocompatibility, process validation and interactive design Determining which technical assessments should be considered for review Steven K. Pollack, Ph.D., Director of the Office of Science & Engineering Labs, FDA Michael Mensinger, Director of Mobile and Cloud Software, DEXCOM Amnon Ptashek, Chief Architect, WESTECH Medical Technologies Paul Krause, Director, Connectivity Systems Engineering, Medtronic 3:30 – 4:00 A Practical Guide to gain Mobile Medical App regulatory approval Exploring the most important takeaways from the Mobile Medical Apps Guidance Best practices for developing apps and getting them approved quickly per FDA What is the definition of a mobile medical app? Determining what current technologies and development platforms are best to support a medical device app Understanding the requirements for device approval and what is meant by enforcement discretion Bakul Patel, Senior Policy Advisor, CDRH FDA Orlando Guillory, Director of Quality Engineering, Edwards LifeSciences Walt Murray, Director of Quality & Compliance Services, MasterControl Seyed Khorashahi, Director, Software Engineering, COVIDIEN William Brodbeck, Director, Regulatory Affairs, STERIS Corporation Dave Flynn, Senior Business Development Manager, MATERIALISE Severine Zygmont, Co-Founder, Oxford Performance Materials 3:30 – 4:00 Legal and intellectual property concerns associated with 3D printing Overview of patent, copyright, and trade secret law Review of current litigation involving 3D printing companies Exploring steps your company should be considering both from an offensive and defensive perspective to address intellectual property concerns Reese Nguyen, Associate Attorney, KEKER & VAN NEST LLP Please feel free to pass on to your colleagues who wish to register! http://mdmwest.mddionline.com/conferencesseminars DAY TWO – WEDNESDAY, FEBRUARY 11th TRACK A: Disruptive innovation in Design of Medical Devices TRACK B: Managing Risk, Quality and Validation TRACK C: Speed to Market, Scale Up & Post Market Compliance DESIGNING THE NEXT-GEN MEDICAL DEVICE: IDEO DESIGN WORKSHOP AND ROUND TABLE TAKING CONTROL OF QUALITY: Dealing with Inspections, Managing Suppliers, and Improving your QMS Securing Finance, Scaling-Up from Concept to Market, and Best Practices in Lean Manufacturing CHAIR: Brian Mason, Director, Design for Health, IDEO 9:30AM – 10:00AM CHAIR: Andrew Harrison, Vice President & General Counsel, Regulatory Compliance Associates KEYNOTE ADDRESS Personalizing Surgery: 3D Printing and The Digital Thread Andy Christensen, Vice President, Personalized Surgery & Medical Devices, 3D Systems Corporation The Founder and CEO of Medical Modeling, who’s company pioneered 3D printing-centric personalized surgery and patient-specific medical device solutions, will present the potential of a new 3D printing technology that will transform the healthcare industry. 10:00AM – 11:45AM IDEO DESIGN WORKSHOP PART 1: Design research and inspiration Improve your ability to deliver great design by learning and practicing key elements of the IDEO design process IDEO, the global design and innovation firm, has a history of delivering impactful, compelling, human-centered design to the world of medical and consumer products. Recently, IDEO received its 18th MDEA award—more than any other company in the world. How to Audit Proof your Processes and Effectively Prepare for an Inspection Financing, Funding and Start-Ups 10:00 – 10:45 Being audit ready at all times in an inconsistent inspection environment What have been the most problematic aspects of FDA audits and inspections over the last 12 months? Defining what true inspection readiness is to pass any inspection with flying colors Focusing your quality programs on the right thing to overcome inspection inconsistencies Discussing if and why audit and inspection challenges going to overtake 510(k) and PMA submission headaches? Uwe Degenhardt, Director, Quality Compliance, EDWARDS LIFESCIENCES 10:00 – 10:45 Startup Shark Tank California 3 hammerhead financiers will grill 4 Californian medical device start-ups on why they should be given finance. Only 1 startup will come out alive. At MD&M, IDEO will lead a fully interactive design workshop allowing the participants to flex their creative muscles and learn how to uncover and prioritize unmet user needs, brainstorm novel and creative solutions, and quickly prototype experiments to test concepts. The Dennett F. Kouri, Jr., JD, Senior Director, workshop will use case studies of existing Quality, Regulatory & Clinical, EDWARDS products on the market to describe the steps and LIFESCIENCES tools of the design process. The sharks and the audience will decide… Anne DeGheest, Managing Director, Healthtech Capital David M. Anderson, Managing Director, GE CAPITAL Rik Vandevenne, Director of Capital Funds, River Cities Capital Funds Please feel free to pass on to your colleagues who wish to register! http://mdmwest.mddionline.com/conferencesseminars Whether you are working on upgrading an existing device or creating a completely novel offering, this hands-on workshop will provide you with some new tools and perspectives in how to deliver disruptive human-centered products to the market. Design research: Uncovering user needs through in-context observations and analogous inspiration Synthesizing insights: Identifying patterns and human-centered insights that will set the foundation for the product design A great group of innovators and designers led by Brian Mason, Director, Design for Health, IDEO Megan Huston, Business Development Associate, IDEO Jason Wilkins, Senior Mechanical Engineer, IDEO 10:45 – 11:05 How to survive an FDA inspection Step by step instructions on how to get a green light first time from the FDA Examining the importance of a mock inspection Best practices in improving your internal auditing and reliability testing protocols It’s all in the prep: Internal pre-audits and tighter controls on data and documents Dawn Haake, Senior Director Global Quality Assurance, NuVasive 11:05 – 11:45 CDRH Quality Update 2015 Hear directly from the FDA where this in-depth presentation and Q&A forum will provide more clarity on quality updates for this coming year. Enforcement trends Quality initiative o Quality information for inspections o Quality library of successful practices William MacFarland, Director of Division of Enforcement, CDRH, FDA 10:45 – 11:05 How to secure funding from a Financier’s perspective Overview of investment trends in early and late stage start ups Discussing the real impact of the reimbursement strategy on finding finance Making sure you have a strong capital efficient business model Discussing future VC finance strategies and what they look for in a medical device start up for long-term success Rik Vandevenne, Director of Capital Funds, River Cities Capital Funds 11:05 – 11:45 PANEL DISCUSSION Learn the secrets to a successful startup An already thriving group of startups will give the audience a closer look at what differentiates them from the many startups who have failed within the medical device industry. David Mills, President & Chief Executive Officer, Dallen Medical Richard Meyst, President & Chief Executive Officer, Fallbrook Engineering Charlie W Chi, Ph.D., President & Chief Executive Officer, Somersault Orthopedics Please feel free to pass on to your colleagues who wish to register! http://mdmwest.mddionline.com/conferencesseminars 1:00PM – 2:30PM IDEO DESIGN WORKSHOP PART 2: Ideation and prototyping Improving your Supplier Quality Strategies for Successful Scale-Up from Design to Manufacturing Brainstorming: Learn seven rules that unlock the creative power of a brainstorming session, to generate a huge range of ideas, opportunities, and concepts—tips you will for sure take back and change how your teams brainstorm Prototyping: Experience the incredibly effective way of making ideas tangible, learning through making, and quickly getting key feedback to learn (or fail) early Feedback: Tools for prioritizing feedback and other design constraints in play A great group of innovators and designers led by Brian Mason, Director, Design for Health, IDEO 1:00 – 1:50 PANEL DISCUSSION Building an airtight supplier quality agreement Detailing best practices in supplier quality audit plans Best practices in how to renegotiate your supplier contracts Supplier risk management – how to comply with changing compliance Discussing FDA guidance for CMO quality agreements David Parkin, Senior Supplier Quality Lead, VOLCANO CORPORATION Megan Huston, Business Development Associate, IDEO Gus Rathgeber, Ph.D., Director of Global Supplier Quality & Vascular Products, DJO GLOBAL 1:00 – 1:50 PANEL DISCUSSION The outsourcing tipping scale: Making it work for you Evaluating the pros and cons of this ever changing outsourcing/inhousing landscape Best methods in utilizing CMO’s expertise Discussing how the digital health movement will bring about new outsourcing partnerships Gaining insight into future outsourcing trends in the BRIC markets Utilizing the CMO’s capabilities to improve time to market MODERATOR: Shriram Venkataramana, Manager, China MedTech Insights, Decision Resource Group Jeffrey Ray, Principal Engineer, Supplier Quality, CareFusion Noreen King, Founder & President, Evolve Manufacturing Technologies Marindy Waldron, Senior Manager, Supply Chain, Procurement and New Projects, St. Jude Medical Barry Kazemi, Chief Executive Officer, Life Science Outsourcing - Jason Wilkins, Senior Mechanical Engineer, IDEO Jarod Oldham, Global Supplier Assurance Manager, St. Jude Medical Julia Wall, Consulting Analyst, Decision Resources Group 1:50 – 2:10 Minimizing supply chain costs on new 1:50 – 2:10 launches and product redesigns Protecting your Intellectual Property (IP) Understanding the impact of launch on when working with your suppliers existing products, materials, and suppliers Conducting Intellectual Property due Streamlining cross-functional NPI and diligence and protection strategies for large redesign projects to minimize costs of and small companies transition Gaining insight into foreign filing Choosing agile suppliers to support ramp considerations, licensing and distribution up of product demand Updates on technology confidentiality and Irina Cantez, Director Global Strategic Sourcing, branding strategies DJO Global Mircea Tipescu, Intellectual Property Attorney, BRINKS, GILSON & LIONE Please feel free to pass on to your colleagues who wish to register! http://mdmwest.mddionline.com/conferencesseminars 2:10 – 2:30 Reviewing the significant developments in EU Medical Devices Regulation and Notified Bodies unannounced visits - Learn the latest on the future for the proposed EU Medical Device Regulation replacing the current Directive - Evaluating the proposed changes to understand the implications for device manufacturers - Making sure your processes support EU expectations and increased scrutiny - Understanding and being prepared for NB unannounced visits now occurring for CE Marking Paul Brooks, Senior Vice President, Healthcare Solutions, BSI Group 2:10 – 2:30 Streamlining your scale-up processes to accelerate speed to market Exploring top 10 must do best practices to shorten concept-to-market time Increasing your efficiency with your current technology Acquiring and agreeing on stable and sufficient product requirements before embarking on development Incorporating user needs and risk management at the start of a product development plan Eric Steuben, Vice President, Operations, Asante Solutions, Inc. Please feel free to pass on to your colleagues who wish to register! http://mdmwest.mddionline.com/conferencesseminars 2:45PM – 4:00PM IDEO DESIGN WORKSHOP PART 3: Innovation thought leadership round table discussion Effectively Implementing a Quality Management System Lean Manufacturing: Beyond the Basics As time permits, bring your specific challenges or questions from inside your design teams, cubicles, lab benches, or fieldwork… and we will engage in a discussion with leading innovation experts about how you can use design thinking and create novel medical device concepts in disruptive ways. Brian Mason, Director, Design for Health, IDEO The importance of a global Quality Management System: Drug Device Combination product case study and workshop The global market for DDC products is expected to grow to $115.1 billion. With many medical device manufacturers partnering with Pharma companies or growing their own DDC portfolio, making sure you have a strong DDC QMS in place should be a priority. This hands-on workshop will discuss examples of internal and external supplier relationship challenges and opportunities in exploring combination product development strategies, as well as the regulatory strategy of DDCs to comply with 21 CFR 210/211 and 21 CFR 820. James Wabby, Director, Quality Systems and Risk Management (Medical Devices and Combination Products), Allergan Lean Transformation for Medical Device Development and Manufacturing Identifying why most lean programs fail to produce lasting results Explaining why a lean transformation model should be based on Key Process Indicators (KPI) and Key Behavioral Indicators (KBI) Exploring how strategy deployment and A-3 thinking can be used to cascade metrics and goals down to the front lines Explaining how to operationalize lean daily management and daily Kaizen using A-3 and the Improvement Kata Darren Dolcemascolo, Senior Partner, EMS Consulting Group William Pratt, Director of Creative Design, KINAMED Matt Duncan, President, Morphix Design Kenny Dang, Vice President, Global Innovation & Development, Lombard Medical Technologies Ken Flaherty, Lead Lean Transformation Consultant, EMS Consulting Group Please feel free to pass on to your colleagues who wish to register! http://mdmwest.mddionline.com/conferencesseminars DAY THREE – THURSDAY, FEBRUARY 12th TRACK A: Disruptive Innovation in Design of Medical Devices TRACK B: Managing Risk, Quality and Validation TRACK C: Speed to Market, Scale Up & Post Market Compliance DESIGNING FOR THE USER: Improving User Experience, Usability Engineering, and Design Controls BEST PRACTICES IN PROCESS VALIDATION AND BIOCOMPATIBILITY TESTING POST MARKET COMPLIANCE CHECK-UP: How to avoid warning letters, submission reviews, and UDI updates CHAIR: Andrew Schaudt, Director of Usability Services, MEDSTAR HEALTH 9:30AM – 10:00AM 10:00AM – 11:45AM CHAIR: Suhas Kulkarni, President, FIMMTECH CHAIR: Elaine H Tseng, Partner, King & Spalding KEYNOTE ADDRESS The Hackers Guide to the Galaxy Jay Radcliffe, Senior Security Consultant & Researcher, Rapid 7 The cybersecurity expert famously known for hacking his own insulin pump in 2011, takes to the stage to question how medical device security has progressed over the last 4 years. Improving User Experience and Usability Overhauling your Process Validation Part 1 How to Avoid Product Warning Letters and Engineering Recalls 10:00 – 10:45 10:00 – 10:45 10:00 – 10:45 PANEL DISCUSSION: Standardizing your validation master plan Effectively responding to 483’s and warning How to design a robust usability study and letters Covering the key principals of process understand the relationship between validation and addressing the main issues Making sure you are not a repeat offender usability testing, risk management, and the industry continues to struggle with Gain insights from interactive case studies and product development examples from other compliance initiatives Defining the regulatory definition of process Designing your study and exploring what validation Highlighting the key 2013/2014 warning letter variables you want to incorporate Encompassing different products and findings Top tricks in early identification of use devices under 1 validation plan Identifying the appropriate course of action errors and preparing for a timely response Designing a better reliability test program Kristen Grumet, Executive Director, Medical Discussing how to best document and and QC testing after validation apply task analysis and use error analysis Using process validation for ISO 14971 risk Devices, NSF International Addressing the constraints of usability reduction 10:45 – 11:15 testing Robert Launsby, President, Preparing for an effective review and response Launsby Consulting Making a strong business case for of medical device recalls Human Factors and demonstrating how it Thomas Oesterle, President, How to survive and manage a successful can directly reduce the bottom line MedHouse Innovations recall Eric Bergman, Human Factors Engineering Determining when a recall is needed 10:45 – 11:15 Director, Fresenius Medical Care Minimizing the current and potential risk WORKSHOP: Improving quality through a Merrick Kossack, Manager, Human Factors Doris M. Apel, Recalls Manager, Varian Medical DoE approach to process validation Engineering, Intuitive Surgical Systems Exploring the advantages of the DoE Tressa Daniels, User Interaction Design approach versus one factor at a time Manager, CareFusion Making sure QSR 820 Part 21 and ISO Joely Gardner, Ph.D., Professor of User 13485 are met Experience & Usability, Cal State Fullerton Please feel free to pass on to your colleagues who wish to register! http://mdmwest.mddionline.com/conferencesseminars 10:45 – 11:15 The ‘How To’ in implementing and executing IEC 62366 How to practice usability above and beyond IEC 62366 Gaining insight into real world case studies on how to follow this new standard Simplifying the standard and detailing essential details for Part 1 and Part 2 Getting to grips on how to obtain FDA approval in Human Factors and usability testing Edmond Israelski, Ph.D. Director Human Factors, Abbvie - How can DoE highlight opportunities to improve quality? Using DoE to demonstrate what variables can be tolerated Robert Launsby, President, Launsby Consulting Thomas Oesterle, President, MedHouse Innovations 11:15 – 11:45 Validation project management rapid workshop Now to get your hands dirty with some process validation practical work. Bounce ideas off your peers, benchmark your process validation procedures and work out your validation kinks to take back to the office. Robert Launsby, President, Launsby Consulting 11:15 – 11:45 Insight: FDA’s Review & Classification of Medical Device Recalls Discussing the fundamentals of medical device recalls Examining the roles and responsibilities associated with a medical device recall Exploring recall related challenges and best practices Jessica Paulsen, Biomedical Engineer, FDA 11:15 – 11:45 Back to the Future: Usability in the Year 2045 Since MD&M West launched 30 years ago, the Thomas Oesterle, President, medical device industry has seen staggering MedHouse Innovations change. Stuart Karten, product designer and 30-year industry veteran, will transport you to the future to imagine what the next 30 years has in store. Come learn how successful medical device companies can create positive user and patient experiences that adapt to tomorrow’s needs. What human factors challenges will shape the industry? Who will use medical devices, and how will their lives, abilities, and expectations change? What’s in store for the burgeoning field of wireless, wearable devices? Stuart Karten, Founder and President, Karten Design Please feel free to pass on to your colleagues who wish to register! http://mdmwest.mddionline.com/conferencesseminars 1:00PM – 2:30PM Designing for Better: Hospital Collaboration, Usability and Design Control Overhauling your Process Validation Part 2 Regulations for the Engineer: Aiming for First Time Submission Approval 1:00 – 1:45 PANEL DISCUSSION: Straight from the hospital’s mouth: Improving collaboration between the end user and manufacturer A panel of physicians will discuss the benefits of bringing the end user into the design stage. This discussion will emphasize the importance of physician feedback: is this considered at the design phase? What is the interaction between engineer and doctor? How can you strengthen your relationship with your end users? MODERATOR: Andrew Schaudt, Director of Usability Services, MedStar Health 1:00 – 1:30 1:00 – 1:30 Validating software used for process Developing a regulatory strategy for fulfilling automation FDA regulatory requirements Participate in this hands-on session to problem Recognizing regulatory opportunities for solve the toughest software process automation achieving company objectives ‘glitches’. Understanding the advantages and What kind of software needs to be disadvantages associated with the pathways validated? to market 21 CFR 820.70(i) requirements of software Anticipating submission requirements for validation for process automation PMA, 510(k), de novo classification and IDE Exploring the 21 CFR Part 11 demands Understanding FDA requirements for device Vincent DeFrank, Software Validation Manager, modifications Philips Healthcare Developing and implementing an effective submission strategy 1:30 – 2:00 Ross Donaldson, MD, MPH, CTropMed, Phil Phillips, President, Phillips Consulting Global validation programs: Sharing the FACER, Director of Emergency Medicine, Group knowledge Global Health Program, Harbor-UCLA Proving the importance and cost saving Medical Center 1:30 – 2:30 opportunities WORKSHOP: Getting your submission Raj Khandwalla, MD, MA, FACC, Director of Discussing the benefits of transforming approved in under 1 hour Cardiovascular Education Cedars Sinai your global validation paper processes to Now that you are even more familiar with the Medical Foundation, Cedars-Sinai Medical electronic various submission processes, you will be given Group and Cedars-Sinai Heart Institute Exploring the best electronic validation group projects to get your teeth into. 3 real life case William B. Armstrong, M.D, Professor of systems available studies that didn’t gain approval first time round – Clinical Otolaryngology-HNS, Chair, Dept. Is there still a language barrier? what lessons can you learn from these previous Otolaryngology-HNS, UNIVERSITY OF Regina Rohe, Senior Director, Global errors? CALIFORNIA Validation, bioMerieux Elaine H Tseng, Partner, King & Spalding 1:45 – 2:30 2:00 – 2:30 Prioritizing Human Factor considerations in ROUNDTABLE DISCUSSION: Process design control Validation Question Time Best practices in building Human Factors Now to get all your questions answered! into your design control program This expert panel of speakers will talk through Identifying the vital role that human some real life case studies and discuss how factors plays in designing a safe and successful process validation procedures and effective device techniques will keep you on track with FDA’s What is the FDA looking for? Quality System Regulation and the Process Exploring Human Factors Engineering Validation Guidance. processes related to Design Control in 21 Robert Launsby, President, CFR 820 Launsby Consulting Dennis Rubenacker, Senior Partner, Thomas Oesterle, President, NOBLITT & RUELAND MedHouse Innovations Vincent DeFrank, Software Validation Manager, Philips Healthcare Regina Rohe, Senior Director, Global Validation, bioMerieux Please feel free to pass on to your colleagues who wish to register! http://mdmwest.mddionline.com/conferencesseminars 2:45PM – 4:00PM 4:00PM – 4:15PM Practical Applications of Design Control Complying with Biocompatibility Testing Standards and Guidance to get your Product to Market Faster UDI: What’s in store for 2015 and beyond? Design control tune-up check Finish off your MD&M West Conference experience with a practical Design Control workshop which will give you more hands-on knowledge on how to identify noncompliance areas and implement improvements to accelerate speed to market. Evaluating different methods of managing the design control process Focusing on design controls related to risk management Understanding the benefits of early implementation and creating innovative test plans Avoiding a slowdown in development and increase in costs Updates on where the FDA is commonly finding noncompliance issues Making sure your regulatory processes fit hand in hand with your design control procedures David Amor, Managing Partner, MEDgineering Biocompatibility testing: All you need to know in 75 mins! This intensive end of day workshop will give you the latest information on how to comply with the new standards. Go back to your office invigorated and up to speed with everything you need to know about biocompatibility testing. Insightful guide to the newest FDA guidance document on biocompatibility What are the main challenges of ISO 10993-1 and how can they be overcome? Exploring FDA expectations for biocompatibility testing Determining which biocompatible tests are best for your products and devices Improving your risk management strategies for testing Edward Reverdy, Ph.D., Director of Global Toxicology & Biocompatibility, Boston Scientific Looking past the regulation: Understanding how UDI will impact your department in 2015 This dedicated UDI session will take both a retrospective look back on the September 2014 deadline for class III medical devices to address how effective the implementation has been, but will also detail what lessons can be learned for the approaching 2015 deadline. Exploring how class II medical device companies can get ready for the deadline Comparing other company UDI methodologies to improve and re-engineer your 2015 implementation Update on international UDI guidance Detailing what additional software and data management requirements will be needed for successful UDI implementation Discussing real case studies where UDI implementation has resulted in better quality and lower costs Dawn Fowler, Senior Manager, Labeling/Documentation/Training, Endologix Thor Rollins, Biocompatibility Specialist, Nelson Laboratories To celebrate the end of a successful MD&M West Conference, we are giving away a free 3D printer. It’s well worth the wait! Please feel free to pass on to your colleagues who wish to register! http://mdmwest.mddionline.com/conferencesseminars

© Copyright 2026