Electric drives Product selection overview

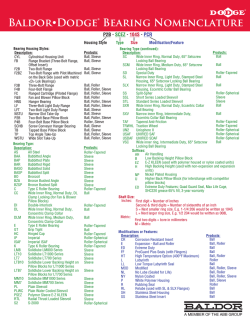

Electric drives Product selection overview Electric axes Electric gantry axes EGC-TB/-BS EGC-HD-TB/-BS ELGR/ELGG DGE-ZR -KF/-RF DGE-SP ELGA-TB-G/ELGA-TB-RF EGSK/EGSP ELGL-LAS DMES Product features Product Drive mechanism Guide mechanism Max. stroke ( Longer strokes on request) Max. speed Max. acceleration Repetition accuracy Max. feed force mm m/s m/s2 ± mm N 8500 5 50 0.1 2500 Rodless EGC-TB Toothed belt Ball bearing EGC-BS Ball screw Ball bearing 3000 2 15 0.02 3000 EGC-HD-TB Toothed belt Ball bearing 5000 5 40 0.1 1800 EGC-HD-BS Ball screw Ball bearing 2400 1.5 15 0.02 1300 ELGR/ELGG Toothed belt Plain bearing, ball bearing 1500 1 3 50 0.1 350 DGE-ZR-KF Toothed belt Ball bearing 4500 3 50 0.1 1500 DGE-ZR-RF Toothed belt Roller guide 5000 10 50 0.1 1500 DGE-SP Ball screw Ball bearing 2000 1.2 6 0.02 1600 ELGA-TB-G Toothed belt Plain guide 8500 5 50 0.08 1300 ELGA-TB-RF Toothed belt Roller guide 7400 10 50 0.08 1300 EGSK/EGSP Ball screw Ball bearing 840 1.48/2 20 0.01/0.005/0.003 392/460 ELGL-LAS Electric linear direct drive Air bearing 1750 4 50 0.01 450 Lead screw Plain bearing or ball bearing 1800 0.05 2.5 0.05 3000 DMES Electric cantilever axes/slides/cylinders DGEA EGSL EPCO ESBF DNCE-BS/-LS DNCE-LAS DFME-LAS ADNE-LAS Product features Product Drive mechanism Guide mechanism Max. stroke Max. speed Max. acceleration Repetition accuracy Max. feed force mm m/s m/s ± mm N 2 Rodless DGEA Toothed belt Ball bearing 1000 3 50 0.05 1000 EGSL Ball screw Ball bearing 300 1.3 25 0.015 450 EPCO Ball screw Not applicable 400 0.5 10 0.02 650 ESBF Ball screw Not applicable 1500 1.35 25 0.01 17000 DNCE-BS Ball screw Not applicable * 800 1 6 0.02 2500 DNCE-LS Lead screw Not applicable * 800 0.07 1 0.07 1000 DNCE-LAS Electric linear direct drive Plain bearing 400 3 125 0.02 202 (FMax ) DFME-LAS Electric linear direct drive Plain bearing/ ball bearing 400 3 83 0.015 202 (FMax ) ADNE-LAS Electric linear direct drive Plain bearing 45 1.9 – 0.1 51 (FMax ) With piston rod Note: * The electric cylinder DNCE can be used together with the guide unit FENG to absorb lateral forces. Drive technology Drive mechanism Features Products Toothed belt • Cost-effective • Long strokes • High speed/dynamic response • Short duty cycles EGC-TB EGC-HD-TB DGE-ZR/-RF ELGA-TB-B/-RF DGEA ELGR/ELGG Lead screw • Medium precision • Self-locking/automatic locking • Cost-effective • Long duty cycles • Positioning movements DNCE-LS DMES Ball screw • High precision • Jerk-free movement • High thrust force • High load rigidity • Medium duty cycles EGC-BS EGC-HD-BS DGE-SP EGSK/EGSP EGSL Linear direct drive • Maximum dynamic response • Extremely short duty cycles • Jerk-free movement • Very short minimum stroke ELGL-LAS DNCE-LAS DFME-LAS ADNE-LAS EPCO ESBF DNCE-BS Guide mechanism design Features Products Plain bearing • Cost-effective • Low speed • Long duty cycles ELGA-TB-G Roller bearing • Cost-effective • High speed up to 10 m/s • Short duty cycles ELGA-TB-RF DGE-RF Recirculating ball bearing • High loads and torques • High speed • Short duty cycles EGC EGC-HD DGE EGSK/EGSP ELGR/ELGG (ball bearing) EGSL DGEA Overview of controllers from Festo Module Compact controller Integrated controller CPX terminal Modular controller Robotic controller Controller CECC-D CECC-LK CODESYS controller CDPX CODESYS controller CPX-CEC-C1 Motion controller CPX-CEC-M1 Modular controller CECX-X-C1 Motion controller CECX-X-M1 Robotic controller CMXR-C1 Robotic controller CMXR-C2 Single axis (ptp asynchronous) Single axis (ptp asynchronous) C1: single axis M1: Interpolation (2D) Single axis (ptp asynchronous) Interpolation (2.5D) Robotic (3D) Robotic (3D) Functionality Maximum number of permissible axes 4 axes: 8 axes: one axis is treated one axis is treated as one CANopen participant. 128 participants as one CANopen (spec. acc. to CANopen). participant. 128 participants (spec. acc. to CAN open). 6 axes interpolated, of which maximum 3 basic axes, 1 orientation axis, maximum 3 dependent auxiliary axes Motion • PtP asynchronous • PtP asynchronous • 3D interpolation with -M1 variants • Each axis moves with its own predefined parameter • The axes do not reach their end positions at the same time and the path is not defined 3D path interpolation with an orientation axis for kinematics with up to 4 degrees of freedom. For example, threedimensional gantry with an axis of rotation on the front unit. Special features • Stand-alone controller • Integration of two fast inputs (200 khz) • 4 IO-Link masters for CECC-LK • CODESYS V3 pbF • Integrated controller in one display • CODESYS • Low-cost engineering with the Festo Configuration Tool (FCT) • Simple programming with Festo Teach Language (FTL) • An optional handheld control unit • Reduced speed in manual operation • Automatic repositioning after interrupted movements • Genuine orientation axes on the front unit • Integrated kinematic models (for Cartesian systems, tripod, H and T-gantry) • Dynamic limiter for optimal cycle time Sample application ptp = point-to-point • Handling systems • Pick & place, palletising • Function integration on the CPX terminal • CODESYS • Handling systems • Pick & place, palletising Other axes (not mutually interpolating) can be actuated via the integrated CODESYS-PLC (ptp asychronous). Recommended: 16 axes • CODESYS-PLC • Encoder interface • Interrupt function • Fast clock pulse inputs • Profibus master • Two CANbus masters • RS 232/ RS 485-A/422-A • PLC Open • SoftMotion • CNC editor • DXF import • Cam disc editor • PLC Open • SoftMotion • CNC editor • DXF import • Cam disc editor Path control, gluing, • Handling systems cutting, handling, flying saw, cam disc • Pick & place, palletising Path control, gluing, cutting, handling, flying saw, cam disc • Enhanced flexibility due to CoDeSys PLC e.g. integration of vision system • Tracking function • Speedindependent path switching points with time compensation, e.g. for gluing applications Handling, palletising, gluing, dispensing, painting, cutting Tracking applications such as processing moving parts on a conveyor belt or synchronised kinematic movement with up to 6 movements Motors and controllers Performance comparison of motors Type Servo (DC) Stepper Servo (AC) Speed Very low (<500 RPM) Low/medium (1000 RPM) High (6600 RPM) Duty cycle Low Medium/high High Festo products MTR-DCI EMMS-ST/CMMS-ST EMMS-AS/CMMx Performance comparison of servo motors and servo controllers 60 NM CMMP-AS 10 CMMS/D-AS CMMS/O-ST 0 1000 2000 3000 4000 EMMS-AS + CMMP-AS EMMS-AS + CMMS-AS/CMMD-AS EMMS-ST + CMMS-ST/CMMO-S 5000 rpm Product features controllers/drives Product Operating modes Setpoint specification Fieldbus Safety Synchronisation Motor feedback interface MTR-DCI • Position • Force • I/O interface • FHPP protocol • CANOpen • Profibus DP • DeviceNet – None • Incremental encoder (integrated) MTR-DCI CMMS-ST EMMS-ST • Position • Speed • Torque • Synchronous • Analogue (±10 V) • I/O interface • FHPP protocol • CANOpen • Profibus DP • DeviceNet STO up to cat. 3, PLd • Master/slave • E-gearing • Incremental encoder (optional) EMMS-ST CMMS-ST CMMO-ST EPCO EMMS-ST • Position • Speed • Torque • I/O interface None STO up to cat. 3, PLe None • Incremental encoder (optional) EPCO CMMO-ST EMMS-ST CMMS-AS CMMD-AS EMMS/E-AS • Position • Speed • Torque • Synchronous • Analogue (±10 V) • I/O interface • FHPP protocol • CANOpen • Profibus DP • DeviceNet STO up to cat. 3, PLd • Master/slave • E-gearing • Absolute encoder (EnDat) • Single turn (Standard) • Multi turn (optional) EMMS/E-ASCMMS-/CMMD-AS CMMP-AS EMMS/E-AS • Position • Speed • Torque • Synchronous • Analogue (±10 V) • I/O interface • FHPP protocol • CANOpen • PROFIBUS DP • PROFINET RT • DeviceNet • EtherNet/IP • EtherCAT STO up to cat. 3, PLd • Master/slave • E-gearing • E-camming • Absolute encoder (EnDat) and resolver EMMS/E-AS CMMP-AS • CANOpen • Profibus DP • DeviceNet – None • Incremental linear encoder with reference switch DNCE-LAS SFC-LACI CMMP-AS-M... SFC-LACI DNCE-LAS DFME-LAS • Position • Speed • Feed force • I/O (digital inputs/outputs) • FHPP protocol STO up to cat. 4, PLe DFME-LAS CMFL ADNE-LAS • Speed • Cycle rate • End position • I/O interface None – None • Incremental linear encoder with reference switch ADNE-LAS CMFL Motor feedback technologies Benefits Incremental encoder MTR-DCI EMMS-ST • Low-cost • Zero position compensation/homing typically required on power up • MTR-DCI retains the last position on power down (memory module) • Standard to RS422 MTR-DCI Single-turn absolute encoder EMMS/E-AS • Absolute values via one shaft revolution • Inductive functional principle, not as sensitive as optical encoders EMMS-ASEMME-AS Multi-turn absolute encoder EMMS/E-AS EMMS-ST • Absolute value via one or more shaft revolutions • Zero position compensation not required if the shaft has completed less than 4096 revolutions (12 bit) • Inductive functional principle, not as sensitive as optical encoders Software PositioningDrives • The right solution with just a few pieces of basic information • Selection and dimensioning of electric axis, motor and gearing Festo Configuration Tool (FCT) • Software for simple commissioning of the drive package (electromagnetic drive, motor and motor controller) • Project and data management for all supported device types Safety function to DIN EN 61800-5-2 and EN 60204-1 The Machinery Directive 2006/42/EC requires numerous safety functions as protective measures for sufficient risk reduction. Festo offers various solution designs for this: from the configurable or programmable safety system CMGA to integrated safety functions STO (Safe Torque Off ) in motor controllers, a second measuring CMGA CMMP-AS-_-M3 with STO module system on linear axes for 2-channel measurement of speed and position and clamping units. Our detailed solutions along with descriptions, parts lists, circuit diagrams, user programs and Sistema project files will help you to implement these safety functions easily in your own applications. EGC with 2nd measuring system EGC with clamping unit on right and left Errors and omissions excepted Companies seeking to be globally successful need to systematically increase their competitiveness. We can support you in achieving this by focusing on our shared goal of improving your productivity. Benefit from the expertise in electric and pneumatic handling systems that we have built up over decades. From front-end units with grippers, vacuum solutions, linear, rotary and swivel drives through to highly complex parallel kinematic and motion control systems. Always the best solution – everything from a single source. en 2013/12 We are a flow of goods. We drive automation for your success. We are your conveyor that never stands still.

© Copyright 2026