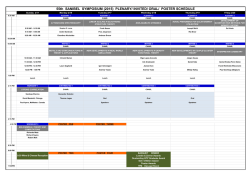

Main Program