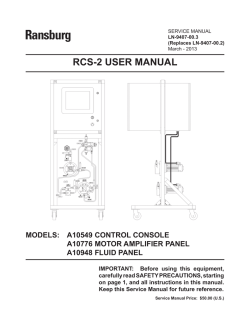

RCS-2 PARTS, MAINTENANCE AND