Technical Program

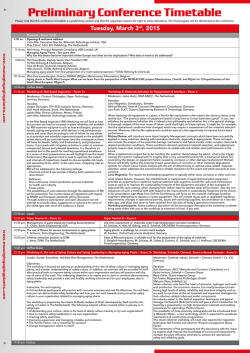

222 Palisades Creek Drive Richardson, Texas 75080-2040 USA WORKSHOP SPE Workshop TECHNICAL PROGRAM 17-18 February 2015 | AT&T Executive Education and Conference Center | Austin, TX, USA SPE/NACE Deepwater Field Life Corrosion Prevention, Detection, Control, and Remediation Technical Program Committee Rodrigo Himiob Wood Group Mustang Sunder Ramachandran Aramco Services Company Jason Hults Genesis Oil & Gas Saadedine Tebbal SET Laboratories, Inc Ashutosh Kak Genesis Oil & Gas Rich Thompson Chevron Victor Keasler Nalco Champion Nicolas Tsesmetzis Shell Khlefa Esaklul Occidental Myles Jordan Nalco Champion Clark Weldon CP Weldon & Associates, Inc Cristina Grigorescu Genesis Oil & Gas Mark McQueen INTECSEA Engineering Sai Venkateswaran BP Chairpersons Binder Singh Genesis Oil & Gas Ken Wunch BP Ting Chen SET Laboratories, Inc This workshop explores field experiences related to corrosion issues on deepwater production platforms. With a design life of typically 20 to 30 plus years, a deepwater production solution must be ‘fit for purpose’ and adaptable enough to accommodate an evolving production stream over the life cycle. This solution may be described as ‘management of change’ (MOC), which if not properly addressed can lead to further problems and costly failures. Materials of containment, coatings, and inhibitors are critical areas pertinent to deepwater mechanical integrity. Coatings can be external for the seawater side or internal for the production fluids side. Inhibitor selection can be a challenge, and chemicals are usually tailored to the composition of the well flow. As the hydrocarbon flow evolves over the productive life of the field, the originally selected materials and coatings design may prove less effective. Likewise, the inhibitor needs may change, such as the use of an alternative inhibitor formulation, or an increase in dose or concentration. These changes could impact environmental constraints and actual volumes required, and therefore impact costs and revenues. With the high cost of production shut-in, and deepwater remediation, it pays to address these issues at the design phase or as a capital expenditure (CapEx), rather than the operating expense (OpEx) phase. During the OpEx phase, changes are far more expensive, and invariably produce further performance risk or safety issues to the asset, environment, and people involved. Deepwater Field Life Corrosion Prevention, Detection, Control, and Remediation General Information: Accessibility Our events and functions are accessible to all attendees with wheelchairs. If you require special arrangements, please contact our staff at the registration desk. Alcohol Policy SPE recognizes the legitimate serving of alcoholic beverages in the process of conducting business and social activities. We also recognize that the use and consumption of alcohol carries with it the requirement for all attendees to consume those beverages responsibly. Commercialism In remaining consistent with workshop objectives and SPE guidelines, commercialism in presentations will not be permitted. Company logos should be used only to indicate the affiliation of the presenter(s). Continuing Education Units Attendees will receive 1.6 CEUs. One CEU equals 10 contact hours of participation. CEUs will be awarded through SPE Professional Development for participation and completion of SPE workshop. A permanent record of a participant’s involvement and awarding of CEUs will be maintained by SPE. Documentation Following the workshop, a url containing released copies of the workshop presentations will be available to attendees. Electronic Devices As a courtesy to the speakers and your fellow registrants, please turn off all electronic devices during presentations. Name Badges Please wear your badge at all times. It is a courtesy to your fellow registrants, speakers and sponsors. Photography Policy SPE reserves the exclusive rights to all recording or reproductions of the workshop. Unauthorized recording is expressly prohibited, whether by video, still or digital camera, mobile phone, or any other means or form of reproduction. Any person attending may be photographed or videotaped, and by your attendance, you give permission to use your image in possible future marketing publications including print, online, and video. Workshop Format Workshops maximize the exchange of ideas among attendees and presenters through brief technical presentations followed by extended Q&A periods. Focused topics attract an informed audience eager to discuss issues critical to advancing both technology and best practices. Many of the presentations are in the form of case studies, highlighting engineering achievements and lessons learned. In order to stimulate frank discussion, no proceedings are published and members of the press are not invited to attend. 17-18 February 2015 | AT&T Executive Education and Conference Center | Austin, TX, USA Schedule at a Glance: All technical sessions are located in Classroom 105. Monday, 16 February 1730-1900 Welcome Reception Carillon Patio Tuesday, 17 February 0700-0800 Registration and Breakfast 0800-0815 Chairpersons’ Welcome 0815-9000 Keynote: Looking Beyond Corrosion 0900-1030 Session I: Materials Challenges – Past, Present and Future: What Have We Learned? 1030-1100 Coffee Break 1100-1230 Session II: Erosion and Erosion-Corrosion – Flow and Material Approaches 1230-1330 Lunch 1330-1500 Session III: Impact of Microbes in High Pressure High Temperature Environments 1500-1530 Coffee Break 1530-1700 Session IV: Monitoring Challenges and Best Practices 1700-1830 Reception Conference Break Area Conference Break Area Tejas Dining Room Courtyard Wednesday, 18 February 0700-0800Breakfast 0800-0845 Keynote: Engineering Practice and the Law 0845-1015 Session V: The Role of Corrosion Testing in the Design of Deepwater Facilities 1015-1030 Coffee Break 1030-1200 Session VI: Corrosion/Scale Prevention in High and Low Velocity Systems 1200-1300 Lunch 1300-1430 Session VII: Cathodic Protection and High-Performance Coating in Deep/Ultra-Deep Applications 1430-1500 Coffee Break 1500-1630 Session VIII: Integrity Management and Life Cycle Design 1630-1700 Wrap-Up Conference Break Area Tejas Dining Room Conference Break Area Deepwater Field Life Corrosion Prevention, Detection, Control, and Remediation Monday, 16 February 1730–1900 Welcome Reception Tuesday, 17 February 0700–0800 Registration and Continental Breakfast 0800-0815 Chairpersons’ Welcome 0815-9000 Keynote: Looking Beyond Corrosion Mike Joosten, ConocoPhillips 0900-1030 Session I: Materials Challenges – Past, Present and Future: What Have We Learned? Chairs: K hlefa Esaklul, Occidental Rich Thompson, Chevron Presentation 1: Metallic Material Selection – Challenges and Evolution for Subsea Well Completions Over the Past Decade Elliott Turbeville, FMC Technologies Presentation 2: Design and Material Considerations For Deep Water Rick Hill, Microalloying International, Inc. Ricky Thethi, 2H Offshore Presentation 3: Use of Life Cycle Cost Analysis (LCCA) for Topside Corrosion Resistant Alloy (CRA) Justification in Hostile Marine Environments Santosh Iyer, Worley Parsons 1030-1100 Coffee Break 1100-1230 Session II: Erosion and Erosion-Corrosion – Flow and Material Approaches Chairs: C ristina Grigorescu, Genesis Oil & Gas Ashutosh Kak, Genesis Oil & Gas Presentation 1: Challenges and Success Stories in Measurements and Predictions of Erosion in Multi-Phase Flow Siamack Shirazi, University of Tulsa Presentation 2: Uncertainties in Erosion Modeling Sandra Hernandez, Chevron Presentation 3: Establishing a Recommended Practice for Erosion Testing of Choke Valves Anwar Sleiman, Master Flo Valve Inc. 1230-1330 Lunch 17-18 February 2015 | AT&T Executive Education and Conference Center | Austin, TX, USA 1330-1500 Session III: Impact of Microbes in High Pressure High Temperature Environments Chairs: Nicolas Tsesmetzis, Shell Victor Keasler, Nalco Champion Presentation 1: Microbial Community Compositions in Seawater Obtained by Sequencing 16S rRNA Genes as Proxies for Microbiologically-Influenced Corrosion Gerrit Voordouw, University of Calgary Presentation 2: Metagenomic Analysis from Onshore and Offshore High Temperature Formations Around the Globe Renato De Paula, Nalco Champion Presentation 3: Understanding the Potential Sources for Microbial Contamination that May Lead to High Pressure High Temperature Associated Biological Reservoir Souring and Microbiologically-Influenced Corrosion Cameron Campbell, Kemira 1500-1530 Coffee Break 1530-1700 Session IV: Monitoring Challenges and Best Practices Chairs: Victor Keasler, Nalco Champion Sai Venkateswaran, BP Presentation 1: Getting Value from Subsea Monitoring – Installation and Performance Requirements for Subsea Corrosion Monitoring George Zener, BP Presentation 2: Internal Microbiologically-Influenced Corrosion (MIC) Monitoring Strategies and Methods for Oil and Gas Assets Rick Eckert, DNV GL Presentation 3: Inspection and Monitoring Challenges in Deepwater Production Chris Dash, ConocoPhillips 1700-1830 Reception Deepwater Field Life Corrosion Prevention, Detection, Control, and Remediation Wednesday, 18 February 0700-0800Breakfast 0800-0845 Keynote: Engineering Practice and the Law Benjamin Escobar, Beirne Maynard & Parsons, L.L.P 0845-1015 Session V: The Role of Corrosion Testing in the Design of Deepwater Facilities Chairs: Saadedine Tebbal, SET Laboratories, Inc. Ting Chen, SET Laboratories, Inc. Presentation 1: The Science and Engineering in Chemicals Qualification and Testing for Deepwater Application Mohsen Achour and Probjot Singh, ConocoPhillips Presentation 2: Selecting Laboratory Test Conditions for Fit-for-Service Oil Country Tubular Goods Material Evaluations Amit Kumar, ExxonMobil Presentation 3: Coarse Grain Polycrystalline to Nano – Addressing Hydrogen Damage, Corrosion and Environmental Cracking in Extreme Environments Indranil Roy, Schlumberger 1015-1030 Coffee Break 1030-1200 Session VI: Corrosion/Scale Prevention in High and Low Velocity Systems Chairs: Sunder Ramachandran, Aramco Services Company Myles Jordan, Nalco Champion Presentation 1: Options for Long-Term Inorganic Scale Control During Deepwater Subsea Well Completions Myles Jordan, Nalco Champion Presentation 2: Design and Application of Corrosion Inhibitors for a High Temperature CO2 Containing High Shear Deepwater System Sunder Ramachandran, Aramco Services Company Presentation 3: High Shear Corrosion Assessment and Mitigation – Available Tools and Critical Considerations Conchita Mendez, ExxonMobil 1200-1300 Lunch 17-18 February 2015 | AT&T Executive Education and Conference Center | Austin, TX, USA 1300-1430 Session VII: Cathodic Protection and High-Performance Coating in Deep/Ultra-Deep Applications Chairs: R odrigo Himiob, Wood Group Mustang Clark Weldon, CP Weldon & Associates, Inc. Presentation 1: Cathodic Protection Technology Modifications Being Made for Deepwater Systems Presentation 2: Achieving Design Life Through an Understanding of the Causes of Failure Brian Gibbs, ABS Group Presentation 3: Coating Challenges and Needs in Deepwater Applications Adriana Paiva, Shell Jim Britton and Matthew Taylor, Deepwater Corrosion Services, Inc. 1430-1500 Coffee Break 1500-1630 Session VIII: Integrity Management and Life Cycle Design Chairs: M ark McQueen, INTECSEA Engineering Jason Hults, Genesis Oil & Gas Presentation 1: Controlling Top of Line Corrosion Debbie Buswell, INTECSEA Engineering Presentation 2: Risk-Based Asset Integrity Management in Harsh Environment Operation Faisal Khan, Memorial University 1630-1700 Wrap-Up Deepwater Field Life Corrosion Prevention, Detection, Control, and Remediation 2015 UNITED STATES EVENTS CALENDAR 6-7 March SPE/AAPL Enhancing the Community Conversation From Acquisition Through Production Workshop San Antonio, TX, USA 22-26 March SPE Physics and Chemistry of Nanoscale Rocks Forum La Jolla, CA, USA 24-25 March SPE Production Chemistry and Chemical Systems Workshop New Orleans, LA, USA 31 March-1 April SPE Production and Reservoir Performance Through Pressure Management Workshop Dallas, TX, USA 21-23 April SPE Bakken-Three Forks Field Development: Past, Present, and Future Workshop Denver, CO, USA 20-22 May SPE Optimizing Liquids-Rich Development: The Story Continues Workshop Palos Verdes, CA, USA 1-5 June SPE Flow Assurance: The Future State of the Art Forum Newport Beach, CA, USA 1-5 June SPE Health and Social Responsibility: The Role of the Oil and Gas Industry on Community Health Forum Miami, FL, USA 11-13 August SPE Distributed Fiber-Optics Sensing for Well, Reservoir, and Facilities Management Workshop Napa, CA, USA 1-2 September SPE From Sensors to Solutions Workshop Galveston, TX, USA 15-16 September SPE/ICoTA Re-Fracturing Opportunities Through Optimization Interventions Workshop San Antonio, TX, USA October SPE Enviromental Stewardship in Oil and Gas Development Workshop USA 20-21 October SPE/ASPE High Pressure High Temperature Applications Workshop Galveston, TX, USA 9-11 November SPE History Matching Workshop TX, USA

© Copyright 2026