Bypass Systems Designed to Improve Efficiency and Flexibility of

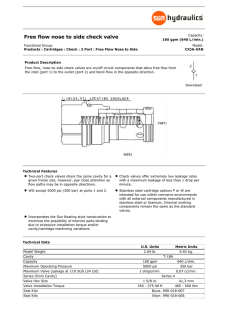

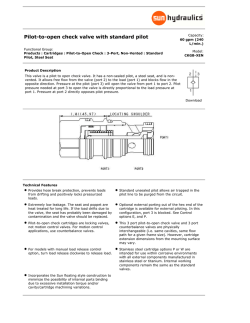

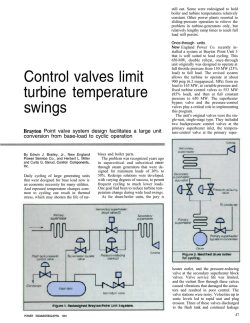

Bypass Systems Designed to Improve Efficiency and Flexibility of Thermal Power Plants ................................................... By Ulrich Kägi 22591 Avenida Empresa Rancho Santa Margarita, CA 92688 949.858.1877 ! Fax 949.858.1878 ! ccivalve.com 390 | 06/00 ! ©2000 CCI ! DRAG is a registered trademark of CCI. In the early 1930’s new boiler types, e.g., the Sulzer monotube Bypass Systems Designed to Improve Efficiency and Flexibility of Thermal Power Plants steam generator, were developed. Because this boiler did not have a large accumulator in the form of a steam drum anymore, it required automatically controlled valves and a fully automatic control system for stable operation. The boiler was started up with the evaporator and superheater full of water and already " By Ulrich Kägi, CCI AG (Switzerland) under pressure. It required therefore a bypass valve at the Presented at the Future Strategies and Technologies for Development of Thermal Power International Conference, Dec. 14–17, 1999, in New Delhi, India outlet of the boiler to control the boiler pressure immediately after light-off, when the water in the boiler expanded and Abstract this type of boiler successfully. steam production started. A fully hydraulic control system and hydraulically operated valves were developed in order to operate T urbine bypass valves were first used in the early 1930’s with the newly developed once-through steam generators. Today, bypass With the development of boilers with reheaters, bypass systems as we know them today, with HP- and LP-bypass, were introduced. Fig.1 shows the water/steam cycle of a single reheat systems are not only essential for the flexible operation of large coal fired power plants, but play an equally important role in power plant with HP- and LP-bypass. In the effort to increase advanced combined cycle power plants. Bypass systems permit the efficiency and reduce cost per installed megawatt, unit sizes were boiler and the steam turbine to be separated during startup, shut- increased along with higher temperatures and pressures at the down and load disturbances. This reduces fuel consumption and superheater and reheater outlet. In the 1960’s the first plants were enhances operational flexibility during all those transient operating operated in sliding pressure mode. modes. Startup and reloading times—and therefore fuel costs—are reduced. Other advantages are reduced lifetime consumption of In continental Europe it became customary to utilize the HP-bypass valves as safety valves to protect the superheater major plant components, and higher overall availability of the against excessive pressure. The design of the bypass valves had plant. The latest bypass-valve technology improvements make sure that bypass systems fulfill all the operational requirements of to follow the trend of ever-increasing steam flow together with higher temperature and pressure. In the 1970s, bypass systems today’s advanced thermal power plants. Longer overhaul cycles and reduced maintenance are important features in today’s increasingly competitive market. New plants are not the only ones that were applied in increasing numbers also to enhance the flexibility of large drum type boiler units. The Indian power industry was at the forefront of bypass application in these power plants. can profit from the advantages of state-of-the-art bypass systems. Bypass systems can be added to existing plants, and existing bypass 2. Function of Turbine Bypass Systems valves can be upgraded to the latest technologies. Turbine bypass systems can contribute to flexible plant operation 1. Introduction mainly by supporting: " Repeatedly attainable fast startups with the greatest possible regard to the lifetime of heavy-walled components. HP IP LP " Quickest possible restoration of power supply to the grid after any disturbance G PT PT 1 3 2 77 C 1 2 3 HP-Bypass Valve Spraywater Control Valve Spraywater Isolation Valve Therefore, bypass systems contribute to the 6 7 8 LP-Bypass Control Valve Desuperheater Spraywater Control Valve electric power at minimum total cost. CL 2.1 7 PT overall target of safe and efficient supply of Plant startup During unit startup, the bypass system 6 essentially allows the separation of boiler and TT C 8 turbine operations by diverting all the steam, which cannot be accepted by the turbine or other consumers, through the bypass. This allows the boiler to reach the desired steam Figure 1—Single Reheat Plant with HP- and LP-Bypass 2 Bypass Systems Designed to Improve Efficiency and Flexibility of Thermal Power Plants | 390 qualities as quickly as possible to start the turbine. ©2000 CCI. All rights reserved. Without a bypass it is difficult to control two output variables of the boiler (pressure and temperature) with only one input o C 500 bar 300 4.2 variable, the firing rate. If there is no steam flow through the reheater and almost no steam flow through the superheater, the firing rate is limited to very low values. Such low firing rates 400 4.1 300 200 do not allow a quick warm-up of the boiler. Increased slagging 200 and fouling of the boiler can be, besides high fuel consumption, the result of slow warm-up. Because of the low boiler load, the attainable superheater outlet temperature is limited. Changes in % 100 0 100 100 the firing rate will always affect pressure and temperature. Fast pressure transients during startup are not desirable because they result in temperature transients in heavy-walled parts, such as the 3.2 boiler drum or the startup separator. 2.1 The bypass therefore allows faster boiler warm-up through higher boiler load, reduces thermal transients in the boiler, and by Bypass Operation 2.3 2.2 1.1 2.4 attaining good steam-to-metal temperature matching also allows 0 0 shorter turbine startup times with reduced life time consumption. Light up 2.1.1 The HP-Bypass During Hot Start 100 50 Synchr. min Full Load Pulverizers The hot start characteristics of a coal-fired 500 MW unit (Fig. 2) shows how a bypass system can contribute to a quick and lifetime-saving startup. The boiler is a once-through type with nominal superheater outlet conditions at full load of 254 bar 1.1 Firing Rate 2.1 2.2 2.3 2.4 Feedwater Flow Waterwall Flow Steam Flow (Superheater) Steam Flow (Turbine) 3.1 Superheater Pressure 3.2 Reheater Pressure 4.1 Superheater Temperature 4.2 Reheater Temperature (3683 psig) and 541oC (1000oF). After an overnight shutdown the unit is restarted at a superheater pressure of approx. 80 bar (1160 Figure 2—Hot start of a coal-fired supercritical 500 MW unit psig). This is, at the same time, the pressure for turbine start, so no large pressure transients are to be expected. Immediately In the startup diagram of Fig. 2, the reheat pressure during startup after light-up, the bypass opens and starts to control constant is kept at 12 bar (175 psig). This keeps the exhaust pressure of the pressure. The firing rate is quickly increased in order to match HP-Turbine low enough to avoid overheating of the last turbine the superheater outlet temperature with the turbine metal stages through ventilation losses. The LP-bypass must therefore temperature. For this unit, the desired steam temperature after be sized for the startup flow at this reduced pressure. an overnight shutdown is approximately 450 oC (842 oF). Two 2.2 Load rejection pulverizers are started before the turbine is started. This keeps temperature transients, invariably associated with the start of the 2.2.1 HP-Bypass first pulverizers, away from the heavy wall turbine parts. The An HP-bypass with capacity of 100% BMCR at rated pressure can, bypass compensates for load swings originating from pulverizer in case of a load rejection or a turbine trip, immediately take start. The reheater pressure is quickly increased to approx. 12 bar over all excess steam. This has the following advantages for the (175 psig) which allows auxiliary steam to be supplied from the plant operation: reheater. 2.1.3 The LP-Bypass During Startup " The boiler can remain in operation and immediate reloading of the turbine is possible The LP-bypass is diverting the hot reheated steam directly to the " No lift of superheater safety valves condenser. The LP-bypass should have at least a capacity which is equal to the HP-bypass flow during startup, including the " Superheater and reheater are continuously cooled by steam flow HP-bypass spraywater flow. The reheater pressure during startup is determined by various considerations: " Unnecessary pressure and temperature transients are avoided " Use of reheat steam as auxiliary steam " The boiler can run back to a stable minimum load in a controlled manner " Desired reheat pressure for IP/LP turbine warming " Desired HP-turbine exhaust pressure for startup ©2000 CCI. All rights reserved. " No immediate pulverizer trips are necessary " House load operation is possible 390 | Bypass Systems Designed to Improve Efficiency and Flexibility of Thermal Power Plants 3 " Reheat steam is available as auxiliary steam 3. Turbine Bypass Systems in Combined-Cycle Power Plants " Part load trip in sliding pressure mode without unnecessary pressure transients Bypass systems are not only essential for flexible operation of large coal-fired power plants, they are also part of any of today’s A smaller bypass of 60–70% MCR usually allows the keeping advanced combined-cycle power plants. Fig. 4 shows the bypass of the boiler in operation. At high loads the superheater safety system of an advanced Combined Cycle Power Plants (CCPP) valves will have to open for a brief period and pressure and with a three-pressure Heat Recovery Steam Generator (HRSG). temperature transients are not avoided completely. 2.2.2 LP-Bypass The purpose of the bypass system in this type of power plant bar Pressure is in principle the same as in the coal-fired plants. It has to 40 compensate for the differences in the startup sequence between Due to limited the steam generator and the steam turbine. The steam production capacity of the of the boiler is determined primarily by the gas turbine operation condenser, the LP-bypass and therefore the available thermal energy at the outlet of the gas 20 turbine. By controlling the steam flow of the HRSG, it is possible usually cannot dump 100% to reach the steam conditions desired for a smooth and lifetime10 bar saving start of the steam turbine. Sizing considerations are similar MCR flow into Flow the condenser. When determining the maximum allowable Bypass Flow 25% 50 100 % Flow limitation Boiler Flow 35% Turbine House Load Flow 10% to those for a coal-fired power plant. The possible separation of the steam generator and the steam turbine during disturbances plays an even-more-important role in the CCPP because the steam generator operation is directly coupled with the gas turbine. The separation therefore allows independent operation Figure 3—LP-Bypass After Load Rejection LP-bypass flow, the high LP-bypass spraywater flow of approx. 25% of steam flow has to be taken into account. On the other hand, it is desirable from a turbine operating point of view, to have for house load operation and reloading a HP-Turbine exhaust pressure as low as possible, and therefore a large LP-Bypass. of gas and steam turbines. 4. Design Considerations Bypass systems are installed to enhance the flexibility of power plant operation and to protect and save life-time of critical plant components. Bypass systems are themselves subject to frequent high thermal stress caused by normal startups and shutdowns The result of the two contradictory requirements is very often a LP Bypass with a 100% MCR capacity at full reheat pressure but a flow limitation introduced in the control system. Fig. 3 illustrates house load operation with an LP-bypass. The operating conditions are assumed as follows: " Minimum stable boiler load approx. 35% " Required steamflow for house load approx. 10% " LP-bypass flow (including HP-bypass spraywater) approx. 25% MCR " Max. reheat pressure of 10 bar (145 psig) at house load (25% of full load pressure) 1 GT HP IP LP G As Fig. 5 shows, the resulting size of the LP-bypass valves is 100% MCR at full reheater pressure. 3 If the maximum allowable flow through the LP-bypass is less than 100%, the reheater safety valves will have to open in the initial phase of a load rejection from full 1 2 3 HP-Bypass IP-Bypass LP-Bypass 2 load. The reheat safety valves have to dump the excess steam to atmosphere until the boiler has been run back to a load corresponding to the capacity of the LP-bypass. 4 Figure 4—Bypass Ssytem in a Combined-Cycle Power Plant Bypass Systems Designed to Improve Efficiency and Flexibility of Thermal Power Plants | 390 ©2000 CCI. All rights reserved. as well as disturbances in the plant operation. Additional stress The wing-type plug used in this is caused by the inherent function of pressure and temperature valve has evolved over many years reduction. Bypass valves must be designed so that they are not by of experience and is the best- themselves a limitation to the operational flexibility of the plant suited stem shape for this type and never result in additional stress or damage to the plant. of valve. The wings split up the steam flow into a number Goals of a good bypass valve design are therefore: of small jets, which efficiently " Tolerance to frequent high thermal stress due to pressure and temperature transients reduces noise and vibration inside " Little regular maintenance required for any mechanical components The valve-in features integrated the valve. spraywater injection. Proper " Easy accessibility to all valve internals for inspection and maintenance design of an integrated injection requires a detailed understanding " Replacement of any parts must be possible without cutting the valve out of the pipe valve during all load conditions. In order to achieve the above goals, the following rules should be Analysis and optimization of applied for the design of bypass valves: these flow patterns including " Thin pressure boundary walls reduce actual thermal stress in the material due to temperature transients of the flow pattern inside the Figure 5—HP-Bypass Valve spraywater atomization and evaporation is today possible with dynamic numerical calculation. " Spherical shapes result in the thinnest-possible pressure boundary walls for given pressure and temperature " Smooth transitions between different wall thicknesses and no unnecessary material accumulation " Pressure boundary walls must be protected from being hit by spraywater " Avoid thermal stress due to temperature differences in any parts which are already subject to high mechanical stress (e.g., no spraywater injection through valve stems) The spray water is injected through a high number of small injection nozzles directly into the zone of highest turbulence of the steam flow. This ensures excellent atomization of the injected water, good mixing with the steam, and due to the small droplet size, very fast evaporation of the injected water. The spraywater nozzle body which is subject to the differential temperature between steam and injection water is not under mechanical load. The cage around the desuperheating area prevents the pressureretaining walls from being hit by water droplets, which would " Efficient cooling of the steam by good mixing and evaporation of the injected water cause high local thermal stress. Hole pattern, shape and material " Good atomization of the injected spraywater by high injection speed or injection into the high steam turbulence zone integrated injections. selection of the cage are the result of long experience with Due to the optimal atomization and evaporation of the " Good mixing of the injected water by high turbulence or deep penetration of the injected water into the steam jet spraywater, the water is essentially evaporated at the outlet of the valve which gives maximum freedom in placing the valve in " All parts must be accessible and exchangeable from the top the plant. The following examples of an HP- and an LP-bypass valve show 4. 2 LP-Bypass Valve the application of the above listed design rules. In the LP-bypass valve shown in Fig. 6, the steam flows in the closing direction. This is the normal flow direction for LP-bypass 4.1 HP-Bypass Valve Fig. 5 is a sectional drawing of an HP-bypass valve. Since this valve is designed to be used also as a combined bypass and safety valves because the LP-bypass usually has a safe closing function to protect the condenser from too high a thermal load. valve, the steam flow is in the opening direction of the valve. The valve has an inlet cage, seat ring and outlet cage, all easily Because the high pressure (thick wall) part of the valve consists removable from the top. essentially only of the inlet nozzle, this design minimizes stress due to thermal cycling. The valve body has a spherical shape to minimize the wall thickness. Any unnecessary material accumulation is avoided. The valve is especially suited as an HP-bypass for supercritical plants. ©2000 CCI. All rights reserved. The spraywater is injected downstream of the valve through spring-loaded nozzles. The outlet cage is guiding the steam flow towards the spray nozzles. The spring-loaded nozzles ensure a minimum injection pressure for all flow rates, and therefore a high injection velocity and good atomization. High spraywater 390 | Bypass Systems Designed to Improve Efficiency and Flexibility of Thermal Power Plants 5 velocity results also in deep penetration of the injected safety valves with sliding pressure opening mode, it is the water into the steam jet LP-bypass controller which generates the signals to keep the at the outlet of the valve, reheater safety valves open as long as there is too much reheat and therefore good mixing steam flow to be dumped only through the LP-bypass. of water and steam. The defined injection velocity makes sure that the injected water is not hitting the pipe walls downstream of the injection nozzles. The nozzles are arranged Figure 6—LP-Bypass Valve during all operating modes. In case of power-operated reheater Because the steam conditions after the LP-bypass desuperheater are usually at or near saturation conditions, the temperature after injection cannot be used as a control signal. The necessary injection water flow and corresponding injection valve position must be calculated on basis of the steam flow and desired conditions after desuperheating. around the whole As mentioned above, the actual signal interchange between the circumference of the pipe, HP-/LP-bypass controller and other control systems is small, and and the number of nozzles the required functions for startup and other operating conditions is selected so that a large can be clearly defined. It is therefore advantageous to procure the area of the steam jet exiting bypass system including bypass controller as one package. The the valve is penetrated by bypass supplier is best suited to implement all required control the injection water. All the above design features together result functions for a smooth operation of the bypass system. This is in a good water/steam mixing and quick evaporation of the certainly the case if safety functions and coordination with power injected spraywater. operated reheater safety valves are involved. 4.3 5. Conclusion Turbine Bypass Controller A well-matched bypass controller will contribute a great deal The main reason for installing turbine bypass systems is to the flexible and lifetime-saving operation of the plant. The improving flexibility in plant operation, especially during startup, bypass is controlling the boiler pressure during the critical period shutdown and disturbed plant operation. Benefits of this of the boiler startup when pressure transients can lead to high enhanced flexibility are faster startup times, reduced downtime, unnecessary temperature transients in heavy walled components and higher availability of the plant, resulting in less fuel costs of the boiler and the turbine. The key part of the HP-Bypass and lower overall plant-operating costs. These desired results pressure controller is the setpoint generator. It has to produce are only achievable when all components are designed and the correct setpoint for all the different operating modes during selected to suit the specific needs of a bypass system, and all startup, load operation, load rejection and shutdown. Core components are well-matched. This is achieved when the whole of the setpoint generator is a rate limiter, which limits the system—valves, actuators, and controls—are from one supplier gradient of any pressure increase during all operating modes, with years of experience in the design and operation of bypass thus protecting the heavy-walled parts from pressure/temperature systems and the ability to integrate all components. A good transients. Operating modes are mainly determined by process technical specification which addresses all the requirements is a conditions, namely the superheater pressure and the valve customer’s most effective instrument in receiving a well-designed position. The bypass controller is therefore independent and and matched bypass system. Some design criteria for reliable does not rely on many signals from the boiler or turbine bypass valves are listed above. controller. 6. References The HP-spraywater control, although at first glance a very simple 1. Assessment of Fossil Steam Bypass Stations EPRI CS-3717, Final Report, 1984 piece of equipment, has to deal with large variations in process gain and time delay as well as process disturbances. The use of an advanced control strategy, i.e., a state controller with observer (SCO), can considerably improve accurate control under different operating conditions, and is therefore an important life- 2. R. Rohner, Sulzer Bypass-Systems for Fossil Power Stations I Mech E Power Conference 1988 3. W. Bung and B. Föllmer, Controlled Safety Valves in Power Plants in Accordance with the German Standards VGB Kraftwerkstechnik 75 (1995) Number 9 conserving factor for valves and piping. The LP-bypass pressure controller controls reheat pressure during startup and load rejections. Similar to the HP-pressure controller, it has a setpoint generator producing the correct pressure setpoint 6 Bypass Systems Designed to Improve Efficiency and Flexibility of Thermal Power Plants | 390 ©2000 CCI. All rights reserved.

© Copyright 2026