External Services-Fire Fighting-Section 3

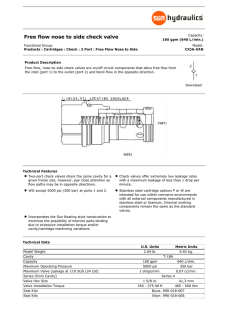

Construction of New Buildings for IIT Madras Research Park – Phase – II, SH: - Building external services – Fire fighting pipeline works LIST OF APPROVED MAKES OF MAJOR MATERIALS FIRE FIGHTING SYSTEM 1) All materials shall be of best quality and ISI Stamped 2) Final choice of makes rests with the clients. Description APPROVED FITTINGS 1) Hydrant Minimax, New age / Firex / Nitin Fire 2) Galvanized Steel pipes Tata, Jindal 3) Rubber lined hose reel Minimax, Dunlop, Newage, Nitin Fire 4) Canvas Hose Minimax, Newage 5) VALVES i) Gun Metal, gate, globe, NR Zoloto, Leader, RB, Jainsons, Kitz ii) Isolation Valve HD / Kitz / Nitin Fire iii) Steel Ball Valves Zoloto, Leader, Kitz, Tyco iv) Motorized Solenoid valve Avcon, R.K. engineering, Kitz, Tyco v) Butterfly valves AUDCO, Keystone, Jainsons, Kitz vi) Y strainer Zoloto, Leader, Kitz, Tyco Technical specification Section -3 Page 1 of 16 Construction of New Buildings for IIT Madras Research Park – Phase – II, SH: - Building external services – Fire fighting pipeline works FIRE HYDRANT SYSTEM 1.0 Scope of work 1.1 The scope of work shall cover supply, installation, testing and commissioning of the fire hydrant system covering the following: a) Hydrant mains, external ring and yard hydrants. b) Landing valves, hose reels, hose cabinets etc. c) Fire brigade breaching, Siamese connections and connections to pumps and appliances. 2.0 Standards 2.1 The fire hydrant installation shall conform to and meet with the requirements set out by the following: 1) IS: 13039-1991 Code of practice for External Hydrant System – Provision & Maintenance 2) IS: 13716-1993 Code of Practice for Fire Safety 3) IS: 3844-1989 Code of practice for installation of internal Fire hydrants and hose reel on premises. 4) Fire Insurance Association of India-Tariff Advisory Committee rules & guidelines. 5) Compliance with the local fire brigade and the fire enforcing authorities. 4.3 3.0 3.1 concerned. System Operation and Control Panels The fire pump shall be started automatically on loss of pressure and the operation sequence of the booster and fire pumps shall be as follows: i) Booster or jockey pump shall start when the system pressure drops by 0.5 Kg/cm2 and stop when the system pressure is re-established. ii) 2 The fire pump shall start when the system pressure drops by 1.0 Kg/cm and shall continue to run till manually switched off. iii) Booster/jockey and fire pump starting shall be indicated on the panel with a red indication lamp. It should also be indicated on the FACP. 3.2 The motor starters (star-delta) shall consist of electrically actuated contactors. The starter shall be complete with ON-OFF push buttons, timers and auxiliary contacts and shall be fully automatic. There shall be an indicating lamp with each of the pumps and an ammeter and selector switch with the fire pumps. Fire pump starting shall be annunciated through an electric siren and the pump shall be capable of being started remotely. Technical condition Section -3 Page 2 of 16 Construction of New Buildings for IIT Madras Research Park – Phase – II, SH: - Building external services – Fire fighting pipeline works 3.3 The starter along with isolator shall be housed in a 2.0mm M.S. box duly rust inhibited through a process of degreasing and phosphating. 3.4 All cabling to starter and control switches shall be carried out through armored PVC FRLS cables of approved makes. Cables shall be laid in accordance with section “M V CABLING”. Cabling from starter or switch to the motor shall be through LAPP steel braided flexible of PVC FRLS cables. The pump motors and panels shall be earthed in accordance with IS 3043-1966 or as shown on drawings. 4.0 Fire Hydrants, & Hose Reels 4.1 Hydrants shall be provided externally as shown on the drawings. Internal hydrants shall be provided at each landing of and escape staircase and additionally depending on the floor area as shown on drawings. Landing valve shall be twin headed gun metal valve with 2-63 mm dia outlets and 100 mm inlet conforming to IS 5290-1998. Landing valve shall have flanged inlet and instantaneous type outlets and mounted at 1.0 m above the floor level. Instantaneous outlets for fire hydrants shall be of standard pattern approved and suitable for 63 mm dia fire brigade hoses. Wherever necessary, pressure reducing orifices shall be provided so as to limit the pressure to 5.5 kg/sqcm or any other rating as required by the local fire brigade. 4.2 External Hydrants a. External Hydrants shall be stand post type over-ground unless shown otherwise. All external hydrants shall be 80 mm C.I butterfly valve. Hydrants shall be located at least 2 m away from and within 15 m from the building wall. b. Each hydrant shall be provided with a hose cabinet containing 2 x 15 m 63 dia unlined flax or controlled percolation hoses with couplings. Wherever shown, the cabinet may contain a branch pipe and nozzle. The cabinet shall be 900 x 600 x 400 fabricated out of 2 mm mild steel sheet duly rust inhibited through a process of degreasing, phosphating etc. The cabinet shall receive two coats of red oxide primer, inside and outside, before 2 coats of final painting of approved shade. The cabinet shall be wall-mounted or free standing with its own steel legs depending on the site conditions and as shown on drawings. c. Alternatively the hoses can be centralized in hose cabinets meeting the requirements. d. The fire brigade connection shall consist of one or two twin-headed 63 mm dia gun metal outlets with build-in check valve and drain plugs connected to a 150 mm dia outlet connection to the water reservoir or to the hydrant main. The fire brigade collecting head shall conform to IS 904-1983. 5.0 Piping 7.1 All piping shall be as specified under “PIPING FOR FIRE FIGHTING” and the schedule of work for piping. 6.0 Test & Commissioning 6.1 All hydrant piping shall be tested for a hydrostatic test pressure of 20 kg/sqcm or 1.5 times the casing pressure of the pump for a period of 24 hours at the end of which there shall be no loss in pressure 6.2 The booster & fire pump starting and stopping shall be tested by opening the test valve and record the following: Technical condition Section -3 Page 3 of 16 Construction of New Buildings for IIT Madras Research Park – Phase – II, SH: - Building external services – Fire fighting pipeline works 1) Booster pump start / stop System pressure at start up Stop Time elapsed from start to stop 2) Hydrant Pump start System pressure at start up : : kg/sqcm kg/sqcm = seconds : kg/aqcm : kg/sqcm Maintained system pressure while discharging the landing valve at the highest point. i) pump end ii) highest outlet : iii) intermediate points kg/sqcm : kg/sqcm 6.3 All the operating tests shall be carried out in the presence of any local authority, Fire Brigade or Insurance Co. Pressures obtaining at each landing valve shall be tested and recorded. Wherever excessive pressure is recorded, the orifice plates shall be replaced. 7.0 Mode of Measurement 7.1 Landing valves with fire hose cabinet with hose reel, rubber line hose, canvas hose, branch pipe, axe, nozzle etc. shall be measured per unit. 7.2 External hydrant stand post type with butterfly valve or sluice valve with tailpieces, etc. shall be measured per unit. 7.3 Fire brigade inlet connection completes with 1 or 2 nos. 63 dia twin head inlets with non-return valve with 100 or 150 dia respectively of inlet pipe at least 1.5 m long shall be measured per unit. 7.4 External Hose reel boxes complete with hoses and enclosure etc. shall be measured per unit. Technical condition Section -3 Page 4 of 16 Construction of New Buildings for IIT Madras Research Park – Phase – II, SH: - Building external services – Fire fighting pipeline works SPRINKLER SYSTEM 1.0 Scope 1.1.1 The scope of work shall cover supply, installation, testing and commissioning of the sprinkler system covering the following: a) Installation valves with motor gong b) Sprinkler Piping 2.0 Standards 2.1.1 The sprinkler installation shall confirm to and meet with the requirement set out by the following: 1) Fire insurance association of India – Tariff Advisory Committee rules 2) Local Fire Brigade and Fire Engineering authorities 3.0 Installation Valves 3.1 The sprinkler system shall incorporate one or more (as shown on drawings) installation valve assemblies comprising: i) A main Gate Valve ii) In and out pressure gauges iii) Test connection of adequate size with valve and orifice plate with pressure connections. iv) Water motor and gong with necessary piping isolation valve and strainer and drain. 3.2 The installation valve shall be straight through type suitable for wet pipe sprinkler systems. Valves shall be of cast iron with gun metal internals and suitable for vertical seal and retaining ring and shall incorporate a suitable non return device to compensate for pressure for smooth water flow for 1) Water valve through a retard chamber 2) Test connection and drain 3.3 There shall be two pressure gauges, one for the mains side and another for the installation side. Each gauge shall have pressure damping brass piping with gunmetal gauge. 3.4 A test connection of adequate size as approved shall be provided with a shut off gate valve, an orifice plate with pressure connections. The discharge from the test connection outlet shall be let to the nearest sump or drain as shown on drawings or as directed. 3.5 The mains water motor gong shall be preferably be of cast gunmetal body and internals. The valve shall have an associated gunmetal gate valve, strainer preceding the water motor. The water motor and gong shall be located on the discharge lead as directed. Technical condition Section -3 Page 5 of 16 Construction of New Buildings for IIT Madras Research Park – Phase – II, SH: - Building external services – Fire fighting pipeline works 3.6 Flow switches and Tamper switches shall be as specified under Fire Hydrant System. 4.0 Piping 8.1 All piping shall be as specified under “Piping for Firefighting” and the schedule of work for piping. 5.0 Testing 5.1 Entire sprinkler piping shall be tested with the sprinklers in position to a hydrostatic test pressure of 1.5 times the casing pressure of the pump and maintained for a period of 48 hours at the end of which there shall be no loss in pressure. 5.2 Test valves in each sprinkler installation shall be opened (with temporary drain connection) and the following observations recorded: 1) 2) 3) 4) Start up of jockey pump Start up of sprinkler pump Operation of water motor gong Operation of tamper switches for shut off valves All branches shall be tested and witnessed and attested by the Engineer in Charge. All the operating tests shall be carried out in the presence of any local authority, Fire Brigade or Insurance company. 6 Mode of Measurement 6.1 Sprinkler pump and jockey pump with mounting frame, vibration mounts excluding concrete foundation shall be measured per unit. 6.2 Flow switches and tamper switches shall be measured per unit and excludes wiring to the Fire Alarm Panel which shall form part of Fire Alarm Wiring. Sprinklers shall be identified as pendant, sidewall, or concealed and paid for per unit. 6.3 For Piping refer section of Piping for Fire fighting. 6.4 Installation valve complete with test valve, orifice plate etc. shall be regarded as one unit. 6.5 Control Cabling from Pressure gauge panel to respective started be measured in running meter length and paid at unit rates. 6.6 Starter with isolator housed in M.S. box for each pump shall be measured as a unit and paid. Technical condition Section -3 Page 6 of 16 Construction of New Buildings for IIT Madras Research Park – Phase – II, SH: - Building external services – Fire fighting pipeline works PIPING FOR FIRE FIGHTING 1.0 Scope 1.1 The scope of work covers, supply, laying, testing and commissioning of the entire piping system for the Fire Fighting Installation i.e. Fire Hydrant and sprinkler systems. 2.0 Standards 2.1 The following standards shall be applicable: i) IS 1239 Mild Steel Tubes & Tubulars And fittings ii) IS 1879 Malleable iron fittings iii) IS 778 Gun Metal gate, globe and Check valves iv) IS 1537 Vertically cast iron double Flanged pipes v) IS 7181 Horizontally cast double flanged pipes. All standards should be the latest. 3.0 Hydrant Mains 3.1 External 3.1.1 Underground external mains shall be either a) Double Flanged class C pipes conforming to IS 7181 or to 1537 upto 300 mm dia or 7.0-kg/sqcm pressures. b) For sizes higher than 300 mm or 7.0-kg/sqcm pressure pipes to IS 1537 shall be class C there shall be no change in class, in respect of pipes to IS 7181. c) Ductile iron or mild steel pipes ERW conforming to IS 1239 upto ERW pipes to IS 3589 or BS 3601. 3.1.2 3.1.3 Where the cast iron double-flanged pipe diameter exceeds 300 mm and system pressure is more than 7 kg/sqcm; class C pipes shall be used. Cast iron pipes shall use only cast iron fittings conforming to IS 1538. All flange joints shall be designed for a pressure rating of 2.0 N/sq mm and joints shall use high tensile bolts with 3mm fiber reinforced Teflon gasket. Pipes shall be given one coat of hot bitumen before being laid in position. Ductile iron or mild steel pipes, when laid underground, shall be protected against corrosion by two coats of hot bitumen and two wraps of fiber glass tissue over the entire length including fittings & valves. Fittings shall be weldable wrought iron fittings suitable for butt-welding and 10% of the welded joints shall be radio graphically tested and found in order. The welded joints shall be random selected for testing in consultation with the Engineer. All flanges shall be slip-on welded flanges to IS 6392 with a 3mm fiber-reinforced Teflon gasket and rated for 2.0 N/sq mm. Technical condition Section -3 Page 7 of 16 Construction of New Buildings for IIT Madras Research Park – Phase – II, SH: - Building external services – Fire fighting pipeline works 3.1.4 Valves 65 mm dia and below shall be heavy duty gun metal full way gate valves or globe valves conforming to IS 778-20 Kg/sqcm class. Valves shall be tested at manufacturer’s works and ISI stamped. Sluice valves above 80 mm shall be cast iron double flanged, with rising spindle conforming to and stamped to ISI 780-20 kg class. Exposed valves shall be provided with wheel for operation and underground valves cap-tops. Contractor shall provide suitable operating keys for sluice valves with tops. 3.1.5 Underground mains shall be laid not less than 750 mm below the ground level and shall be at least 2m away from the building face and supported on concrete pedestals at every 3.5m and held on with galvanized iron clamps. Concrete thrust anchors shall be provided at all bends and tees as shown on drawing and as directed. All excavation for pipe laying shall be carried out with sufficient width for making proper joints. Backfilling shall be done only after the piping is hydrostatically pressure tested. Piping shall be constantly kept clean till tested. 3.1.6 All valves shall be housed in brick masonry chambers over 150 mm cement concrete (1:3:6) foundation. The brick walls of the chamber shall be plastered inside and outside with 20mm cement sand plaster 1:4 with a floating coat of neat cement. Chambers shall be 650 x 650 mm clear for depths upto 900 mm and 1000 x 1000 mm for depths beyond. Each chamber shall have a cast iron surface box approved by the local Fire brigade. 3.1.7 Piping laid above ground shall be supported on cement concrete (1:3:6) pedestals raising the bottom of the pipe at least 150mm over the ground level and held to the pedestals with galvanized clamps. Pedestals shall be made at 3.0 m center to center. Cement concrete 1:3:6 thrust anchors shall be provided at all tee-off points and change of direction. Pipes laid on walls and ceiling shall have galvanized steel brackets. 3.3 Painting 3.3.1 All exposed piping for fire fighting shall be distinctly painted ‘Fire Red’ shade 536 to IS:5-1978. Pipes shall first receive two coats of red oxide primer uniformly applied and two coats of oil paint applied thereafter. All pipes supports shall be painted black as specified for support & clamps. 4.0 Testing & Commissioning 4.1 All piping after installation shall be tested for a hydrostatic test pressure of 20 Kg/Sqcm maintained for 24 hours. All joints and valves shall be checked for leaks and rectified and retested. During testing all valves except drain & air valves shall be kept fully open. 5.0 Makes of Materials 5.1 The following makes of materials are listed as conforming to the specifications. Cast Iron Pipes 1) Indian Iron & Steel 2) Kesoram 3) Electrosteel castings Galvanized Steel Pipes 1) Indian Tube (Tata) 2) Zenith 3) Gujarat Steel Tube 4) B.S.T/Apollo Steel Tubes Technical condition Section -3 Page 8 of 16 Construction of New Buildings for IIT Madras Research Park – Phase – II, SH: - Building external services – Fire fighting pipeline works Fittings 1) RM Engineering Works Ahmedabad 2) KS Engineering Works Ghaziabad Valves 1) Leader 2) Kirloskar 3) G.G. (Bombay Metals & Alloys) 6.0 Mode of Measurement 6.1 All external piping shall be measured along the center line of the pipe and paid per unit length and shall include: i) All Pipes & Fittings ii) Bituminous coating 6.2 All internal piping shall be measured similarly but shall include for the pipe supports and clamps instead of excavation. 6.3 All valves, air valves, drain valves together with flanges or tail pieces shall be measured per unit. 6.4 All excavation and concrete supports and thrust blocks shall be measured as per drawing and paid for per cum. PAINTING 1.0 Scope 1.1 The scope of work covers painting of: 1) 2) All equipment Piping & pipe supports 2.0 All surfaces to be painted shall be thoroughly cleaned with wire brush to remove completely rust and other extraneous substances. Over the cleaned surfaces one coat or red oxide primer shall be applied completely covering the exposed surfaces. Out finish coat of painting shall be applied one day after the prime coat, after ensuring that the paint is dry. The second coat shall be done before the installation is handed over and after approval to do so from the Engineer-in-charge. 3.0 Mode of measurement 3.1 All painting shall form part of the cost (Item Rate) of equipment, piping etc. No separate payment shall be admissible. Technical condition Section -3 Page 9 of 16 Construction of New Buildings for IIT Madras Research Park – Phase – II, SH: - Building external services – Fire fighting pipeline works TECHNICAL CONDITIONS 1. ASSOCIATED CIVIL WORKS 1.1 Civil works associated with fire fighting installation are included the scope of this Contract for civil work like core cut, wall breaking, wall chasing by wall chaser, Making holes & making good, chambers, buried Hume pipe (including excavation & Refilling) etc. 1. PROJECT EXECUTION AND MANAGEMENT The Contractor shall ensure that senior planning and erection personnel from his organization are assigned exclusively for this project. The Contractor shall appoint one Project Manager holding senior management position in the organization. He shall be assisted on full time basis by a minimum of two firefighting engineer & three senior supervisors. The entire staff shall be posted at site on full time basis. Separate ID card to be given by the Contractor to each worker working on site. The project management shall be through modern technique. The Contractor’s office at site shall be fully equipped with fax, computers & plotter and shall prepare proper bar chart and completion schedules to be submitted & ensure timely completion. Erection engineer and supervisors shall be provided with mobile communication system so that they can always be reached. For quality control & monitoring of workmanship, contractor shall assign at least one fulltime engineer who would be exclusively responsible for ensuring strict quality control, adherence to specifications and ensuring top class workmanship for the fire fighting installation. Contractor shall furnish details of licenses of supervisors/workmen to be employed at site. Following manpower deployment shall be provided by the contractor:a. b. c. d. e. f. One Project Director 1 Senior Engineer (minimum 10 years experience) & 1 Junior Engineer (5 years experience). 2 Senior Supervisors 1 QA/QC Engineer (Part Time) 1 Housekeeping in charge with at any given time minimum 3 years experience. 1 Store Keeper. 2. FEES AND PERMITS The Contractor shall pay any and all fees and obtain permits required for the installation of this work. On completion of the work, the contractor shall obtain and deliver to the Owner, certificate of final inspection and approval by the local electricity authority (CFO/ Municipal, State/Central govt. whichever is applicable) 3. DRAWINGS The fire fighting Drawings listed under Section-6, which may be issued with tenders, are diagrammatic only and indicate arrangement of various systems and the extent of work covered in the contract. These Drawings indicate the points of supply and of termination of services and broadly suggest the routes to be followed. Under no circumstances shall dimensions be scaled from these Drawings. The architectural/interiors drawings and details shall be examined for exact location of equipment, pipe lines. Technical condition Section -3 Page 10 of 16 Construction of New Buildings for IIT Madras Research Park – Phase – II, SH: - Building external services – Fire fighting pipeline works The contractor shall follow the tender drawings in preparation of his shop drawings, and for subsequent installation work. He shall check the drawings of other trades to verify spaces in which his work will be installed. The contractor shall examine all architectural, structural, plumbing, HVAC and other services drawings and check the as-built works before starting the work and report to the Owner’s site representative any discrepancies and obtain clarification. Any changes found essential to coordinate installation of his work with other services and trades, shall be made with prior approval of the Architect/Consultant/ Owner’s site representative without additional cost to the Owner. 4. SPECIFICATIONS The Specifications shall be considered as part of this contract. The Drawings indicate the extent and general arrangement of fire fight works. These drawings are essentially diagrammatic. The Drawings indicate the point of termination of conduit runs and broadly suggest the routes to be followed. The work shall be installed as indicated on the Drawings. However, any change found essential to coordinate the installation of this work with other trades shall be made without any additional cost to the Owner. The data given herein and on the Drawings is as exact as could be secured, but its complete accuracy is not guaranteed. The drawings are for the guidance of the contractor, exact locations, distances and levels shall be governed by the site conditions and the Architectural & Interior layouts. 5. SHOP DRAWINGS 10.1 All the shop drawings shall be prepared on computer through AutoCAD System based on Architectural Drawings, site measurements and Interior Designer’s Drawings. Within eight weeks of the award of the contract, contractor shall furnish, for the approval of the Architect/ Consultant, two set of detailed shop drawings of all equipment and materials including layouts for all conduit layouts, distribution panels, switch boards, cabinets, special pull boxes, cable trays and any other requirement to be fabricated or purchased by the contractor. Contractor shall prepare shop drawing based on the coordinated service drawing issued by the Architect / Consultant. 10.2 These shop drawings shall contain all information required to complete the Project as per specifications and as required by the Architect/Consultant/Owner’s site representative. These Drawings shall contain details of construction, size, arrangement, operating clearances, performance characteristics and capacity of all items of equipment, also the details of all related items of work by other contractors. Each shop drawing shall contain tabulation of all measurable items of equipment/materials/ works and progressive cumulative totals from other related drawings to arrive at a variation-in-quantity statement at the completion of all shop drawings. Each item of equipment/material proposed shall be a standard catalogue product of an established manufacturer strictly from the manufacturers listed in Section 5. When the Architect/Consultant makes any amendments in the above drawings, the contractor shall supply two fresh sets of drawings with the amendments duly incorporated along with check print, for approval. The contractor shall submit further 4 sets of shop drawings to the Owner’s site representative for the exclusive use by the Owner’s site representative and all other agencies. No material or equipment may be delivered or installed at the job site until the Technical condition Section -3 Page 11 of 16 Construction of New Buildings for IIT Madras Research Park – Phase – II, SH: - Building external services – Fire fighting pipeline works contractor has in his possession, the approved shop drawing for the particular material/ equipment/installation. 10.3 Shop drawings shall be submitted for approval sufficiently in advance of planned delivery and installation of any material to allow Architect/Consultant ample time for scrutiny. No claims for extension of time shall be entertained because of any delay in the work due to his failure to produce shop drawings at the right time, in accordance with the approved programme. 10.4 Manufacturers drawings, catalogues, pamphlets and other documents submitted for approval shall be in four sets. Each item in each set shall be properly labeled, indicating the specific services for which material or equipment is to be used, giving reference to the governing section and clause number and clearly identifying in ink the items and the operating characteristics. Data of general nature shall not be accepted. 10.5 Samples of all materials like values, flanges & insulation etc shall be submitted to the Owner’s site representative prior to procurement. These shall be submitted in two sets for approval and retention by Owner’s site representative and shall be kept in their site office for reference and verification till the completion of the Project. 10.6 Approval of shop drawings shall not be considered as a guarantee of measurements or of building dimensions. Where drawings are approved, said approval does not mean that the drawings supersede the contract requirements, nor does it in any way relieve the contractor of the responsibility or requirement to furnish material and perform work as required by the contract. 10.7 Where the contractor proposes to use an item of equipment, other than that specified or detailed on the drawings, which requires any redesign of the structure, partitions, foundation, wiring or any other part of the mechanical, architectural layouts; all such re-design, and all new drawings and detailing required therefore, shall be prepared by the contractor at his own expense and gotten approved by the Architect//Consultant/ Owner’s site representative. 10.8 Within four weeks of approval of all the relevant shop drawings, the contractor shall submit four copies of a comprehensive variation in quantity statement, and itemized price list of recommended (by manufacturers) imported and local spare parts and tools, covering all equipment and materials in this contract. The Project Manager shall make recommendation to Owner for acceptance of anticipated variation in contract amounts and also advise Owner to initiate action for procurement of spare parts and tools at the completion of project. 6. ACCESSIBILITY The Contractor shall verify the sufficiency of the size of the shaft openings, clearances in wall cavities and suspended ceilings for proper installation of his conduits cables, cable trays, panels etc.. His failure to communicate insufficiency of any of the above, shall constitute his acceptance of sufficiency of the same. The Contractor shall locate all equipment which must be serviced, operated or maintained in fully accessible positions. The exact location and size of all access panels, required for each concealed control damper, valve or other devices requiring attendance, shall be finalized and communicated in sufficient time, to be provided in the normal course of work. Failing this, the Contractor shall make all the necessary repairs and changes at his own expense. Access panel shall be standardized for each piece of equipment / device / accessory and shall be clearly nomenclature / marked. Technical condition Section -3 Page 12 of 16 Construction of New Buildings for IIT Madras Research Park – Phase – II, SH: - Building external services – Fire fighting pipeline works 7. MATERIALS AND EQUIPMENT All materials and equipment shall conform to the relevant Indian Standards and shall be of the approved make and design. Makes shall be strictly in conformity with list of approved manufacturers as per Section-3. The Contractor shall be responsible for the safe custody of all materials and shall insure them against theft or damage in handling or storage etc. A list of items of materials and equipment, together with a sample of each shall be submitted to the Owner’s site representative within 15 days of the award of the contract. Any item which is proposed as a substitute, the contractor shall state the credit, if any, due to the Owner in the event the substitution is approved. All changes and substitutions shall be requested in writing and approvals obtained in writing from the Owner’s site representative. 8. MANUFACTURERS INSTRUCTIONS Where manufacturer has furnished specific instructions, relating to the material and equipment used in this project, covering points not specifically mentioned in these documents, manufacturer’s instructions shall be followed in that case. 9. COMPLETION CERTIFICATE On completion of the fire fighting installation a certificate shall be furnished by the Contractor countersigned by the licensed supervisor, under whose direct supervision the installation was carried out. This certificate shall be in the prescribed form as required by the local, state/central govt. / municipal / fire authorities concerned. 15. INSPECTION AND TESTING The Owner may carry out inspection and testing at manufacturer’s works for this contract. No equipment shall be delivered without prior written confirmation from the Owner’s site Engineer. In case factory inspection is carried out then all travelling and lodging expenses for two persons one from owner and one from consultants shall be borne by the Contractor, also all expenses related to testing shall be to Contractor account. Tests on site of completed works shall demonstrate the following: That the equipment installed complies with specification in all respect and is of the correct rating for the duty and site conditions. That all items operate efficiently and quietly to meet the specified requirements. That all circuits are fully protected and that protective devices are properly co-ordinate. That all non-current carrying metal parts are properly and safely grounded in accordance with the specification and appropriate Codes of Practice. The contractor shall provide all necessary instruments and labour for testing, shall make adequate records of test procedures and readings, shall repeat any tests requested by the Owner and shall provide test certificate signed by a authorized person. Such test shall be conducted on all materials and equipment and tests on completed work as called for by the Owner at contractor’s expenses unless otherwise called for. If it is proved that the installation or part thereof is not satisfactorily carried out then the contractor shall be liable for the rectification of the same. Owner Site Engineer’s decision as to what constitutes a satisfactory installation shall be final. All tests shall be carried out by a test house approved by the Owner / Consultants. Technical condition Section -3 Page 13 of 16 Construction of New Buildings for IIT Madras Research Park – Phase – II, SH: - Building external services – Fire fighting pipeline works 16. COMPLETION DRAWINGS Upon completion of the work and before issuance of certificate of virtual completion the contractor shall submit to the Owner’s site representative four set of layout drawings in progressive manner for individual systems drawn at approved scale indicating the complete wiring system as installed. Drawing shall be prepared on AUTO-CAD (latest version). Along with the hard copies, the contractor shall submit copies of all drawings on CD and one set of all drawings on RTF shall also be submitted. These drawings must provide: 17. OPERATING INSTRUCTION & MAINTENANCE MANUAL Upon completion and commissioning of part fire fighting system the contractor shall submit a draft copy of comprehensive operating instructions, maintenance schedule and log sheets for all systems and equipment included in this contract. This shall be supplementary to manufacturer’s operating and maintenance manuals. Upon approval of the draft, the contractor shall submit four (4) complete bound sets of typewritten operating instructions and maintenance manuals; one each for retention by Consultant and Owner’s site representative and two for Owners Operating Personnel. These manuals shall also include basis of design, detailed technical data for each piece of equipment as installed, spare parts manual and recommended spares for 4 year period of maintenance of each equipment. 18. ON SITE TRAINING Upon completion of all work and all tests, the Contractor shall furnish necessary operators, labour and helpers for operating the entire installation for a period of thirty (30) working days of ten (10) hours each, to enable the Owner’s staff to get acquainted with the operation of the system. During this period, the contractor shall train the Owner’s personnel in the operation, adjustment and maintenance of all equipment installed. 19. MAINTENANCE DURING DEFECTS LIABILITY PERIOD 19.2 Complaints The Contractor shall receive calls for any and all problems experienced in the operation of the system under this contract, attend to these within 10 hours of receiving the complaints and shall take steps to immediately correct any deficiencies that may exist. 19.2 Repairs All equipment that requires repairing shall be immediately serviced and repaired. Since the period of fire fighting Maintenance runs concurrently with the defects liability period, all replacement parts and labour shall be supplied promptly free-of-charge to the Owner. Technical condition Section -3 Page 14 of 16 Construction of New Buildings for IIT Madras Research Park – Phase – II, SH: - Building external services – Fire fighting pipeline works 20. UPTIME GUARANTEE The contractor shall guarantee for the installed system an uptime of 98%. In case of shortfall in any month during the defects liability period, the Defects Liability period shall get extended by a month for every month having shortfall. In case of shortfall beyond the defects liability period, the contract for Operation and Maintenance shall get extended by a month for every month having the shortfall and no reimbursement shall be made for the extended period. The Contractor shall provide log in the form of diskettes and bound printed comprehensive log book containing tables for daily record of all temperatures, pressures, humidity, power consumption. Starting and stopping times for various equipments, daily services rendered for the system alarms, maintenance and record of unusual observations etc. Contractor shall also submit preventive maintenance schedule. Each tenderer shall submit along with the tender, a detailed operation assistance proposal for the Owner’s site representatives / Consultant’s review. This shall include the type of service planned to be offered during Defects Liability Period and beyond. The operation assistance proposal shall give the details of the proposed monthly reports to the Management. The tenderer shall include a list of other projects where such an Operation Assistance has been provided. 21. METHOD OF MEASUREMENT The works shall be measured in accordance with relevant IS codes. Notwithstanding any general or local custom, except where otherwise specifically described or prescribed in the contract. 22. DEMONSTRATION TO OWNER At completion, devices subject to manual operation shall be operated at least five times in presence of Owner’s site representative to demonstrate satisfactory operation. 23. PARTIAL ORDERING Owner through the Architect/Consultant/ Owner’s site representative reserves the right to order equipment and material from any and all alternates, and /or to order high side and /or low side equipment and materials or parts thereof from one or more Tenderers. Technical condition Section -3 Page 15 of 16 Construction of New Buildings for IIT Madras Research Park – Phase – II, SH: - Building external services – Fire fighting pipeline works 1. LIST OF MAIN DOCUMENTS AND SUBMITTALS S. No. Items Remarks a. 4-Copies of Performa Invoice 4- sets of Technical Literature Packing Specifications. b. Performance Guarantee c. All Permits d. Technical Data e. Manufacturer’s Drawings, Catalogues Pamphlets & Other Documents f. Variation in Quantity Statement. g. Fire fighting Installation Certificate. h. Operating Instructions & Maintenance Manual m. Testing, Adjusting and Balancing & Note: The above list is only for guide line of the contractor. The contractor shall thoroughly check all document and submittals required as per the tender document and submit them in time as per the requirement. Technical condition Section -3 Page 16 of 16

© Copyright 2026