MV 184 P - Engineering Technology Group

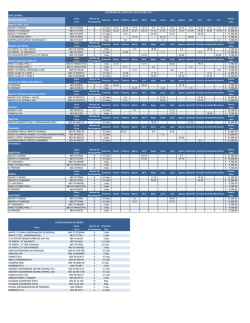

Quaser MV Series MV 184 P Vertical Machining Centre Quaser MV Series The MV range of vertical machining centres offers high speed, high power machining and a rigid cast iron frame with large X & Y travels on a compact footprint. Control: (F):FANUC (T):HEIDENHAIN (M):MITSUBISHI (S):SIEMENS Technical specification: Technical data Work range Table size (mm) Travel X / Y / Z (mm) Spindle nose to table surface (mm) Table load capacity (kg) Feed drive Feed force X / Y / Z (N) MV154 / MV184 P 12B 15C 9B 900 x 500 1,200 x 600 700* / 530 / 560 1,020 / 610 / 610 150 ~ 710 100 ~ 710 500 F T M S 40 / 40 / 36 (T) (S) F T M S 7/ 6/ 5 6/ 5/ 5 6/ 5/ 3 Spindle output kW (S6-40%) Spindle torque Nm (S6-40%) T Spindle transmission Spindle diameter (mm) - Ø45 / P = 16 / 16 / 12 Dia. & pitch of the ball screw Accuracy Positioning / Repeatability ISO 230-2 JIS 6338 (300 mm) VDI 3441 Main spindle Spindle model Max. spindle speed Spindle base speed 6,951 / 6,951 / 13,666 - 4,712 / 4,712 / 11,519 6,951 / 6,951 / 11,310 4,712 / 4,712 / 14, 37 Rapid movement X / Y / Z (m/ min) Acceleration X / Y / Z (m/ s2) 0.008 / 0.004 ± 0.003 / ± 0.002 0.008 / 0.004 F/ M T/ S F/ M T/ S F/ M T/ S 9,000 12,000 1,125 1,500 / 1,125 / 1,125 1,500 / 1,500 25 (1) / 25 / 22.5 159(1) / 212 (1) / 212 / 191 159 / 144 Belt 40 Taper Ø70 15,000 1,400 / 2,000 / 2,000 25 (1) / 21.9 / 21.9 171(1) / 105 / 105 Coupling 48 & 60 (opt.) M WWW.ENGTECHGROUP.COM/BRIDGEPORT 5 TEL 01926 818 418 FAX 01926 818 414 [email protected] BRIDGEPORT UK RHODES HOUSE, NORTHFIELD ROAD, SOUTHAM, CV47 0FG75 L / min., 3 bar -Nozzle coolant -Through spindle coolant -Wash down © Engineering Technology Group Ltd. No part of this literature may be reproduced without permission. M 24A 25 L / min., 8 bar 75 L / min., 3 bar 24,000 2,860 / 24 / 80 / Motor spindle Quaser MV Series MV 184 P 1,125 S Tool changer Tool selection Magazine positions Max. tool diameter (mm) Max. tool dia. Due to neighbor pots are empty Max. tool length (mm) Max. tool weight (kg) CTC time-ISO 10791-9 (sec.)-60Hz Coolant system Coolant tank capacity (Liter) Pump capacity(5) -Nozzle coolant -Through spindle coolant -Wash down Machine size Height (mm) Floor space W x D (mm) (4) 30 ATC 48 / 60ATC Weight (kg) Connections Main power Power consumption (KVA) 1,500 2 2,000 MV154 / MV184 P 12B 15C 9B Random 30 (std.) 48 & 60 (opt.) 76.2 125 280 7 4 (F) (T) 5 (S) 24A 76.2 200 4.5 8 (T) 300 75 L / min., 3 bar 25 L / min., 8 bar 75 L / min., 3 bar 3,030 / 3,065 (F) 3,000 / 3,035 (T) (S) 2,930 / 2,860 (F) (T) (S) 2,540 x 2,600 / 2,760 x 2,800 (F) (T) (S) 3,020 / 2,885 (T) 2,540 x 2,625 / 2,540 x 3,005 2,760 x 2,830 / 2,760 x 3,210 (F) (T) (S) 6,400 / 7,390 (F) (T) (S) 25(F) (T) (S) 200V / 60Hz or 400V / 50Hz 30 (F) (T) 28 (S) 31 (T) Note: * MV154 with X travel 762 mm (30" ) also available - Machine spec. might be different from the catlog if there is any spec. update. 1,125 1 1,500 S 2 22.5 2 2,000 21.9 48 & 60 (opt.) M 5 M 2,860 / - 2 22.5 21.9 Control: (F):FANUC (T):HEIDENHAIN (M):MITSUBISHI (S):SIEMENS Technical specification (continued): Technical data 1 -Nozzle coolant -Through spindle coolant -Wash down 75 L / min., 3 bar 25 L / min., 8 bar 75 L / min., 3 bar WWW.ENGTECHGROUP.COM/BRIDGEPORT TEL 01926 818 418 FAX 01926 818 414 [email protected] 28 BRIDGEPORT UK RHODES HOUSE, NORTHFIELD ROAD, SOUTHAM, CV47 0FG alsopermission. © Engineering Technology Group Ltd. No part of this literature may be reproduced without 30 (F) 2,860 / - Quaser MV Series MV 184 P Technical specification (continued): Main spindle: (B) Belt spindle (C) Coupling spindle (M) Motor spindle 9B P 12B Work range MV154 / MV184 15C 24A 900 x 500 1,200 x 600 700* / 530 / 560 1,020 / 610 / 610 150 ~ 710 100 ~ 710 500 Feed drive 4,712 / 4,712 / 11,519 6,951 / 6,951 / 11,310 4,712 / 4,712 / 14,137 6,951 / 6,951 / 13,666 - - 40 / 40 / 36 (F) (T) (S) 7/ 6/ 5 6/ 5/ 3 Main spindle 9,000 1,125 / 1,125 / 1,125 212(1) / 212 / 191 T 25(1) / 25 / 22.5 Belt 12,000 1,500 / 1,500 / 1,500 159(1) / 159 / 144 Ø70 - 6/ 5/ 5 - - 700 / 530 / 560 900 / 610 / 610 17,279 / 17,279 / 23,562 16,965 / 20,499 / 20,499 24 (T) 10 / 10 / 8.5 10 / 10 / 8.5 - - Ø45 / P = 8 / 8 / 8 0.008 / 0.004 ± 0.003 / ± 0.002 0.008 / 0.004 15,000 1,400 / 2,000 / 2,000 25(1) / 21.9 / 21.9 171(1) / 105 / 105 Coupling 40 Taper 24,000 2,860 / 24 / 80 / Motor spindle Ø70 R 7 24A 24 (F) (T) Ø45 / P = 16 / 16 / 12 Accuracy Positioning / Repeatability M 15C 15,000 1,400 / 2,000 / 25(1) / 21.9 / 171(1) / 105 / Coupling Ø70 24,000 2,860 / 24 / 80 / Motor spindle Ø70 48 & 60 (opt.) 5 WWW.ENGTECHGROUP.COM/BRIDGEPORT TEL 01926 818 418 FAX 01926 818 414 [email protected] BRIDGEPORT UK RHODES HOUSE, NORTHFIELD ROAD, SOUTHAM, CV47 0FG © Engineering Technology Group Ltd. No part of this literature may be reproduced without 28 permission. Quaser MV Series MV 184 P Technical specification (continued): Main spindle: (B) Belt spindle (C) Coupling spindle (M) Motor spindle 9B Tool changer W Coolant system 12B P MV154 / MV184 15C 24A Random 30 (std.) 48 & 60 (opt.) 76.2 200 4.5 8 (T) 76.2 125 280 7 4 (F) (T) 5 (S) 15C M 24A 76.2 125 280 7 4 (F) (T) 76.2 200 4.5 8 (T) 300 75 L / min., 3 bar 25 L / min., 8 bar 75 L / min., 3 bar Machine size 75 L / min., 3 bar 25 L / min., 20 bar 75 L / min., 3 bar 3,030 / 3,065 (F) 3,000 / 3,035 (T) (S) 2,930 / 2,860 (F) (T) (S) 3,020 / 2,885 (T) 2,540 x 2,600 2,760 x 2,800 (F) (T) (S) 3,030 / 3,065 (F) 3,000 / 2,930 (T) 3,020 / 2,885 (T) 2,540 x 2,625 / 2,540 x 3,005 2,760 x 2,830 / 2,760 x 3,210 (F) (T) (S) 6,400 7,390 (F) (T) (S) Connections 200V / 60Hz or 400V / 50Hz 30 (F) (T) 28 (S) 31 (T) 25 (F) (T) (S) Note: * MV154 with X travel 762 mm (30'') also available - Machine spec. might be different from the catalog if there is any spec. update. 30 (F) (T) 48 & 60 (opt.) 7 5 WWW.ENGTECHGROUP.COM/BRIDGEPORT TEL 01926 818 418 FAX 01926 818 414 [email protected] BRIDGEPORT UK RHODES HOUSE, NORTHFIELD ROAD, SOUTHAM, CV47 0FG © Engineering Technology Group Ltd. No part of this literature may be reproduced without 28 permission. 31 (T) Quaser MV Series MV 184 P Options and accessories: =Standard =Option =N/A Standard / Option accessories 9B MV154 / MV184 P 12B 15C QUASER mill i X X ● ● FANUC 31iB ● ● AICC II (Look-ahead 200 blocks) FANUC - data server O O FANUC - high speed processing (Look-ahead 600 blocks) O O HEIDENHAIN iTNC530 ● ● X X HEIDENHAIN TNC620 O O HEIDENHAIN Option2 SIEMENS 828D ● ● X X MITSUBISHI M70 (package A) X X MITSUBISHI M720 Tooling – BT40 ● ● O O – ISO40 & DIN X X – HSK A63 Pull stud for BT tooling ● ● ● ● Balance tooling for spindle warm up ● ● Spindle re-greasing system BBT spindle attachment (simultaneous contact) ● ● ● ● Spindle ECO cooler O Spindle oil chiller(1) O 30 position tool magazine ● ● 48 position tool magazine O O 60 position tool magazine O O ATC auto door O O ● ● 4th axis preparation O O Ø255 mm rotary table & tail stock Panel MPG ● ● O O Remote MPG ● ● Transformer Linear encoder O O O O Coolant through ball screw O O Spindle nose thermal compensation package (Z direction<15μm) O O Work probe Tool length / breakage measurement O O Coolant wash down & wash gun ● ● ● ● 8 bar through spindle coolant 20 bar through spindle coolant 50 bar through spindle coolant Stainless steel chip pan ● ● Cutter air blast ● ● Chip conveyor ● ● Mist collector Documentation ● ● Foundation bolts & blocks ● ● Work light ● ● Machine status light ● ● CE & EMC (4) Note: - For C series ambient temperature greater then 35°C,the cabinet heat exchanger is required. Linear encoder Coolant through ball screw Laser tool measurement X ● ● O O ● X O ● X X ● O O ● ● ● ● X ● ● O O O ● O ● O ● O O O O O ● ● 24A X X X X X ● X O X X X X X ● X ● X (Oil-Air) X X ● ● O O O ● O ● O ● O O O O O ● ● ● ● ● ● ● ● ● ● ● ● ● ● ● ● Work probe WWW.ENGTECHGROUP.COM/BRIDGEPORT TEL 01926 818 418 FAX 01926 818 414 [email protected] BRIDGEPORT UK RHODES HOUSE, NORTHFIELD ROAD, SOUTHAM, CV47 0FG © Engineering Technology Group Ltd. No part of this literature may be reproduced without permission. Quaser MV Series MV 184 P Options and accessories: 9B X ● ● O O ● X O ● X X ● O X ● ● ● ● ● O ● O O O ● O ● O ● O O O O O ● ● O O ● ● ● O ● ● ● ● O 12B P X ● ● O O ● X O ● X X ● O X ● ● ● ● ● O ● O O O ● O ● O ● O O O O O ● ● O O ● ● ● O ● ● ● ● O MV154 / MV184 15C X ● ● O O ● X O ● X X ● O O ● ● ● ● X ● ● O O O ● O ● O ● O O O O O ● ● O O ● ● ● O ● ● ● ● O 24A X X X X X ● X O X X X X X ● X ● X (Oil-Air) X X ● ● O O O ● O ● O ● O O O O O ● ● O O ● ● ● O ● ● ● ● O 15C X ● ● ● ● ● X ● X X X ● O O ● ● ● ● X ● ● O O O ● O X ● ● ● ● ● O O ● X ● O ● ● ● O ● ● ● ● O M 24A X X X X X ● X ● X X X X X ● X ● X (Oil-Air) X X ● ● O O O ● O X ● ● ● ● ● O O ● X ● O ● ● ● O ● ● ● ● O - For C series ambient temperature greater then 35°C,the cabinet heat exchanger is required. Mist collector 4th axis Filtration unit Oil chiller WWW.ENGTECHGROUP.COM/BRIDGEPORT TEL 01926 818 418 FAX 01926 818 414 [email protected] BRIDGEPORT UK RHODES HOUSE, NORTHFIELD ROAD, SOUTHAM, CV47 0FG © Engineering Technology Group Ltd. No part of this literature may be reproduced without permission. Quaser MV Series MV 184 P MV154 C / E / P / M 10C / 12C 9B / 12B A* 2,930 15C 3,030(F) 3,000(T) Chip conveyor 465 24A B C MV184 C / E / P / M 10C / 12C 2,860(F) 15C 3,065(F) 3,035(T) Chip conveyor 465 3,000 3,020 M720 A* B 95 9B / 12B C 24A MV184 X=700 2800 X=1020 -X +X +X 1510 2465 590 ° 465 1922 2981 592 383 85 C (opt.) C (opt.) 889 889 2450 2461 A A 365 350 60 ° -X R6 Y=610 2600 1375 Y=530 42 3 R8 R84 60 B 350 1532 R6 0 3005 (60ATC) 66 2287 88 R 95 R6 B 3210 (60ATC) 580 3191 700mm for coolant tank service 2070 60 2936 2,885 M720 Note: * for (M) & (S) please refer to page 19-20 MV154 2,860 700mm for coolant tank service Installation dimension Pull stud and applicable tools 45˚ Ø19 30˚ 45˚ Ø7 20 26 54 M16X2.0P 44.5 16.4 28.1 1.75 15˚ 11.15 44.106 M16X2.0P 25 14.026 M16X2.0P Ø7 Ø17 Ø22 DIN (69872-A) Ø18.95 1.524 19.106 Ø18.796 ISO (7388-B) Ø7 Ø17 Ø22.5 Ø125 Ø76.2 L Please ref. page 19-20 BT 40 Ø17 Ø23 WWW.ENGTECHGROUP.COM/BRIDGEPORT TEL 01926 818 418 FAX 01926 818 414 [email protected] BRIDGEPORT UK RHODES HOUSE, NORTHFIELD ROAD, SOUTHAM, CV47 0FG © Engineering Technology Group Ltd. No part of this literature may be reproduced without permission. Quaser MV Series MV 184 P Table dimension X MV154 MV184 500 600 900 Y Q 1200 50 100 2 100 100 12 Y 32 100 100 Q 18H 8 Q 30 X 4th axes GV255HB A Y Travel X Travel K D L G MV184 B 265 305 D 251 C E M F MV154 A J I E C H B F 265 251 352 300 300 I 350 510 J 350 98 55.5 510 30 147.5 L 392.5 392.5 N 900 1200 M O 352 192 250 K GV255HB+ST255 192 305 G H N 265 O 190 230 P 300 R 35 Q 385 190 470 515 385 35 GV255HB+Fixture 2 R Q P WWW.ENGTECHGROUP.COM/BRIDGEPORT TEL 01926 818 418 FAX 01926 818 414 [email protected] BRIDGEPORT UK RHODES HOUSE, NORTHFIELD ROAD, SOUTHAM, CV47 0FG © Engineering Technology Group Ltd. No part of this literature may be reproduced without permission.

© Copyright 2026