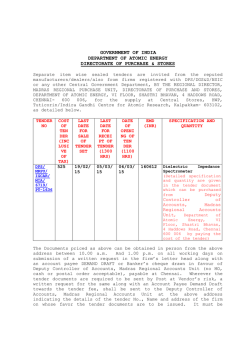

dps/mrpu/igcar/cap/8156/tpt-1639 - Indira Gandhi Centre for Atomic

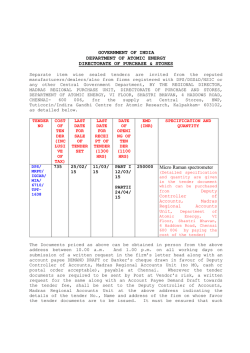

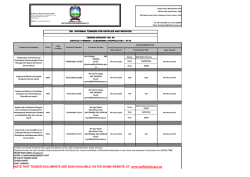

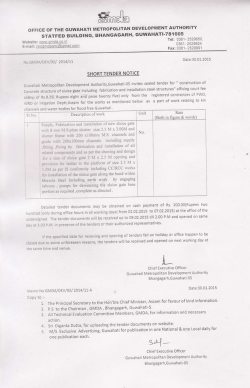

GOVERNMENT OF INDIA DEPARTMENT OF ATOMIC ENERGY DIRECTORATE OF PURCHASE & STORES Separate item wise sealed tenders are invited from the reputed manufacturers/dealers/also from firms registered with DPS/DGS&D/NSIC or any other Central Government Department, BY THE REGIONAL DIRECTOR, MADRAS REGIONAL PURCHASE UNIT, DIRECTORATE OF PURCHASE AND STORES, DEPARTMENT OF ATOMIC ENERGY, VI FLOOR, SHASTRI BHAVAN, 4 HADDOWS ROAD, CHENNAI- 600 006, for the supply at Central Stores, HWP, Tuticorin/Indira Gandhi Centre for Atomic Research, Kalpakkam603102, as detailed below. TENDER NO DPS/ MRPU/ IGCAR/ CAP/ 8156/ TPT1639 COST OF TEN DER (INC LUSI VE OF TAX) 735 LAST DATE FOR SALE OF TENDER SET LAST DATE FOR RECEI PT OF TENDER (1300 HRS) DATE OF OPENI NG OF TEN DER (1100 HRS) EMD (INR) SPECIFICATION AND QUANTITY 24/02/ 15 10/03/ 15 PART I 11/03/ 15 340000 AFM with liquid cell and force spectroscopy PARTII 24/04/ 15 (Detailed specification and quantity are given in the tender document which can be purchased from Deputy Controller of Accounts, Madras Regional Accounts Unit, Department of Atomic Energy, VI Floor, Shastri Bhavan, 4 Haddows Road, Chennai 600 006 by paying the cost of the tender) The Documents priced as above can be obtained in person from the above address between 10.00 a.m. And 1.00 p.m. on all working days on submission of a written request in the firm’s letter head along with an account payee DEMAND DRAFT or Banker’s cheque drawn in favour of Deputy Controller of Accounts, Madras Regional Accounts Unit (no MO, cash or postal order acceptable), payable at Chennai. Wherever the tender documents are required to be sent by Post at Vendor’s risk, a written request for the same along with an Account Payee Demand Draft towards the tender fee, shall be sent to the Deputy Controller of Accounts, Madras Regional Accounts Unit at the above address indicating the details of the tender No., Name and address of the firm on whose favor the tender documents are to be issued. It must be ensured that such request should be sent in advance to reach this Directorate at least 10 days prior to the last date for sale of tender. The envelope should be super scribed with the wordings “Request for issue of tender document against Tender No._________________”. Alternatively prospective bidders can download the set of Technical Specifications along with the, instructions, terms and conditions, from the web link mentioned below and submit the completed format along with applicable tender fee, EMD and all applicable documents much before the due date of tender opening. However in the case of two part tenders, bidders can submit their Part-I and Part-II offers in separate covers (size: S-8) in different colors, in sealed envelopes/wrappers, by clearly and legibly super-scribing the appropriate Part Number of their offers in bold letters and the covers have to be kept in a single cover which is also to be superscribed with TENDER REF No. & DUE DATE, and submitted accordingly. Link for downloading Standard Tender Annexure: http://www.igcar.gov.in/tenders For all indigenous contracts FORM DPS-P 11 and for all Imported contracts FORM DPS-P.12 may be downloaded as the case may be from http://www.dpsdae.gov.in/StdTenderForms.asp The tenderer shall submit along with the tender, Earnest Money Deposit (EMD) as mentioned above in the form of Demand Draft or Banker’s Cheque from any Nationalized / Scheduled Banks drawn in favor of Deputy Controller of Accounts, Madras Regional Accounts Unit, Chennai. Any offer not accompanied with the EMD shall be rejected summarily as non-responsive. The EMD of the unsuccessful bidders shall be returned within 30 days of the end of the bid validity period. The same shall be forfeited if the tenderers withdraw their offer after the tender opening during the bid validity period. The Government shall not be liable for payment of any interest on EMD or any depreciation thereof. However, those who have valid registration with DGS&D, NSIC or DPS as on the date of submission of bids are exempted from payment of EMD. Brief information about our public tender is also available at http://www.igcar.gov.in/tenders and http://tenders.gov.in/department.asp?id=256. For terms and conditions, instructions please visit http://www.dpsdae.gov.in REGIONAL DIRECTOR, MADRAS REGIONAL PURCHASE UNIT HAS THE RIGHT TO REJECT ANY OFFER IN PART OR IN FULL WITHOUT ASSIGNING ANY REASON. REGIONAL DIRECTOR ========== ANNEXURE TO TENDER NO: DPS/MRPU/IGCAR/CAP/8156/ TPT-1639 1. Description of the ITEM : Atomic Force Microscope with liquid cell, force spectroscopy module and accessories: 2. Detailed SPECIFICATIONS and Quantity: Atomic Force Microscope with liquid cell, force spectroscopy module & accessories: Qty: 1 No. Supply, installation and performance demonstration of a high resolution multiple mode AFM with capabilities to image biological and materials samples in liquids and air. The system should have an open architecture to mount on an existing inverted optical microscope so that simultaneous operation of AFM and optical microscope in various contrast imaging modes are possible. 1. AFM system Qty: 01 No. Important specifications: a) Modes Of operation ( closed-loop): in air: contact AFM, Resonant Mode (semi and non-contact), Phase Imaging, Force Modulation, Adhesion Force Imaging, Magnetic Force Microscopy. in liquid: contact AFM, Resonant Mode, Adhesion Force Imaging, Force Modulation (FxD) b) Design: AFM should have Tip Scanning or sample scanning design. System must be reconfigurable from one scanning type to another using the same software and AFM controller (in XY & Z). Cantilever deflection noise should be less than 6 pm rms. c) Liquid safe Features: The AFM head should be liquid-safe design with integrated barrier and special encapsulated piezo drives. The system should have removable probe holder for air and liquid. It should be possible to remove completely the cantilever holder to autoclave or clean using ultrasonic bath with acids, detergents or solvents. Preferably, it should have a chemically inert cantilever holder. d) Sample size: AFM stage should accommodate sample holders like petri dishes, slides, cover slips, and preferably equipped with external magnetizer. Sample size ~30 mm diameter or more and ~ 10 mm height or more. Sample weight ~50 g or more. e) Imaging features: A force curve based imaging mode should be available for samples like soft samples (biomolecules, colloidal spheres etc. ), sticky samples (polymers or bacteria), loosely attached samples (Nanotubes or virus particles in fluid) etc. This mode should offer automatic control over the tip-sample interaction force at every pixel of the image without a need for set point or gain adjustment while scanning. It should provide the collection of F-D curve at 3 kHz/sec (or higher) speed and direct quantitative measurements of Elastic modulus, Adhesion, electric current etc. f) Force Spectroscopy Mode: The system should include basic force spectroscopy mode and advanced force spectroscopy mode (point, line, grid). User must be able to freely combine segments of force-distance curves. It should have set force ramps, temperature ramps, pulling speed or force feedback, and enhanced force mapping capabilities. g) Scanner: The AFM should have closed loop capacitive feedback on X, Y and Z piezo. The AFM should have a large area XYZ Scan range of ~ 90x90x 9 µm or more and a small area XYZ Scan range of ~ 1x1x1 µm (±10%). The scanner should allow operation in air and liquid. Large area scanner must be able to provide small scans up to 50×50 nm without artifacts and small area scanner should be able to provide small scans up to 1×1 nm. Noise level (rms) in XY Noise level (rms) in Z Linearity error : 0.2 nm or less : 0.06 nm or less : 0.03% or less. h) Image quality: It should have a feature that will enhance imaging quality in liquid with cantilevers commercially available from any cantilever manufacturers and should be able to use extremely small oscillation amplitudes in the range of a few nm or less. i) Temperature sensor: The system should have temperature sensors to monitor and control of atmosphere during the measurements. j) Visual imaging systems: It should have a Top view optical system with a possibility to observe cantilever and sample. Side view to control tip to sample approach process, color CCD camera and display, optical adapter to select the scan area on the sample, long focal length continuous zoom video microscope (Optical objectives for magnification 10x or better, Resolution: ~3-4 micro meter). The image should be available in the SPM software in standard image format for storing and processing, Specimen rough adjustments with manual XY range 5×5 mm with a resolution of 5 micro meters to assist automatic approach system. The base shall have stand for video microscopes. k) AFM Controller Hardware: 24bit high precision AD conversion ; 24bit DAC scan generation, High speed, low noise design DSP for highest speed and flexibility; Thermal noise cantilever calibration, lock-ins with appropriate band-pass for multi-frequency modes, 360 degrees phase detection, USB interface with PC, operation in HV and LV mode. A multipurpose AFM head and single software for control of AFM and image processing (detailed specification of the system should be provided by the supplier). l) Computer Specification : Intel Core i7 Quad Core 860 2.80GHz, 4GB DDR3 RAM, 1 TB SATA hard disk, HDD cooler & silencer, 3D accelerator graphics card 9800GT, passive cooling, 2xDVI DVD writer, 4 x USB 2.0. 2 x FireWire, Keyboard and mouse, 2x25” LED/TFT displays. Data acquisition and image processing software for all the modes indicated in item a, should be installed in the computer. Essential Accessories 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. Small volume open fluid cell for applications like single molecules. Qty: 01 no. Small volume closed fluid cell with flow-through possibility. Qty: 01 no. Closed liquid cell, Petri dish holder and Heater (temperature RT to 60°C, stability ~0.1°C) Qty: 01 no. Active vibration isolation platform (Active damping for 0.6-200 Hz, passive damping for >200 Hz; ~ 100 kg max. load. Table top (~ 450 X 405 mm) to accommodate the system and accessories (item 1 a-j) Qty:01 Acoustic and electric enclosure (with glass window) and its base to Accommodate item 1a-j Qty: 01 NC/TM/IM/Close contact mode Cantilevers (Si, Sin) Qty: 150 nose Biological liquid imaging and force Spectroscopy Cantilevers Qty: 150 nose Point probe force modulation cantilevers Qty: 10 nos. Super sharp cantilevers (1-3 nm radius) Qty: 20 nose MFM Cantilevers Qty: 10Nos. Universal holder for Petri dish, slides, cover glass Qty: 1 Mica and cover slips for specimen mounting Qty: 4 sets of 10 each Top View Optics with CCD color camera (3 micron resolution) Qty:1 no. Force spectroscopy software Qty: 01 Desired accessories: 16. Alumina substrates Qty: 1 set 17. Additional Glass cantilever holder kit including 2 springs Qty: 2 nos. 18. Nano manipulation and lithography hardware and software Qty: 01 19. AFM Tip spring constant calibration module for quantitative Analysis for force spectroscopy Qty: 01 20. Biocompatible glues for sample fixation and cantilever changing tool Qty:1 set 21. Calibration gratings for scanner lateral and vertical calibration, detection of lateral non-linearity, determination of tip shape, hysteresis Qty:1 set Most important: Detailed specifications of the make and manufacturer of the items 2-21 must be provided. Other Requirements: a. The closed loop operation should be possible in XY and also in the Z-direction for cell mechanics and adhesion studies. b. During alignment of Laser-on-tip, the laser spot must be visible on screen. c. It should have an automatic cantilever tuning and tip approach (resonance search). Cantilever calibration method to be thermal noise method and thermal noise acquisition (auto approach) d. The system should be capable of coupling with any commercial inverted optical microscopes for simultaneous AFM and conventional optical imaging. e. One set of tweezers, clean gas spry for removing dust from sample, double-sided sticky tapes, tool kits, sample and tip exchange tool kit etc. should be supplied. f. Installation should be done by an engineer from principal manufacturer. If cost is involved, it should be indicated in the offer. g. After the installation, training on operation (all the features), sample preparation, imaging, force spectroscopy and maintenance of the system should be provided at site for duration of 5 working days. Besides, advance training should be provided at site for 3 days, ~ 3 months after installation. If cost is involved, it should be indicated in the offer. h. The AMC cost for 5 years after the warranty period should be indicated. Important: • • • • • • • • • • • • Quotation will be treated incomplete, if all essential accessories and components are NOT included in the offer. A printed catalog with detailed specifications should be supplied or such details available on supplier’s website shall be indicated in the offer. Evaluation will be based on all the essential accessories. List of the users where similar system has been supplied and installed should be provided for evaluating the firm’s capability by the user department. Offers submitted by third party dealers should provide a declaration from the original manufacturer that the after sales support will be provided by the Principle manufacturer. The offer should accompany the cost of all spares and consumables for FIVE years of operation.(Price to be mentioned in part-II only)* Training on operation, sample preparation, imaging, force spectroscopy and maintenance of the system should be provided at the factory/R&D centre of the company at the time of predispatch inspection (for ~ 2 days). The cost for the PDI, if any* (except travel/accommodation/meals) should be indicated in the offer. (part-II) During PDI, items B-M of acceptance criterion shall be demonstrated. All necessary accessories required for the installation of the system should be included in the offer and supplied along with the system. Only the lab space and electrical points would be provided by the buyer for installation. Installation, demonstration and complete training should be given at the site (IGCAR). Manuals and operating instructions of the system (in English language) should be supplied along with the system. All input supply voltage is 230 (± 10%) V AC, 50 Hz. The system should have a minimum THREE year warranty from the date of installation. *all price elements should be indicated in PART-II ONLY. • *UNPRICED BID SHOULD ACCOMPANY PART-I. Acceptance criterion: A. B. C. D. E. F. G. H. I. J. K. L. M. Complete installation, training and demonstration of the system Stability with respect to thermal drift of the system should be demonstrated XY (0.2nm) and Z (0.06 nm) Noise Level in small area scan should be demonstrated Imaging at full scan area of 90 x 90 micro meters for large area scan and demonstration for image resolution less than 50 nm with the specified noise levels of all three scanners. Liquid, air imaging at minimum scan area of 1 x 1 micro meter for small area scanner and demonstration for its image resolution of 1 x 1 nm. Imaging of a DNA, CNT and emulsion droplets of average size 200 nm (samples are provided by end-user. Scanner lateral and vertical calibration using gratings should be demonstrated Functionality of all the modes Adhesion force imaging at the film and substrate interface should be demonstrated Software functionality against the features mentioned Force Spectroscopy (force-distance) curves on colloidal samples supplied by user. Direct measurement of elastic modulus, adhesion, electric current and long-range forces using non-oscillatory mode. Demonstration of F-D curves acquisition speed up to 3 kHz/sec. Operation in liquid cells and Petri dish (K.GEETHA) ASSISTANT PURCHASE OFFICER ANNEXURE TO TENDER NO.DPS/MRPU/IGCAR/CAP/8156/TPT-1639 Very Important Note 1) Price information should NOT be given in Part-I. Prices should be given only in the price bid (Part II). The price breakup of different systems / accessories/spares, if any, should be given in Part II. However, unpriced bid containing the list of items quoted along with taxes & levies to be shown separately in part -I. The unpriced bid should contain exactly the same item description provided in the price bid. If the unpriced bid does not accompany the offer, it is liable to be rejected. 2) Unsigned offers or offers with scanned signature will be rejected: Scanned/unsigned offers are not acceptable and such offers shall be rejected outrightly without any further reference to the tenderer. 3) In case of Two part tender participating vendors shall not submit any revised price bid unless specifically called for by the purchaser(DPS).suo-moto submission of revised price bid shall not be entertained. 4) AMC of the machine is mandatory and it shall be for 5 years or more after expiry of warranty. (K.GEETHA) ASSISTANT PURCHASE OFFICER

© Copyright 2026