dps/mrpu/igcar/mia/6719/pt-1636 - Indira Gandhi Centre for Atomic

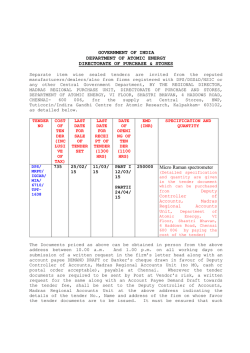

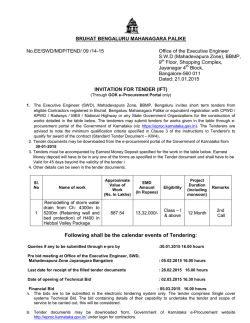

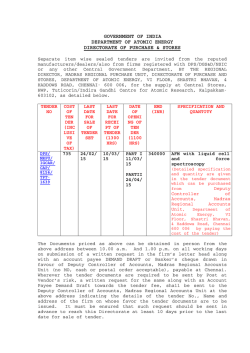

GOVERNMENT OF INDIA DEPARTMENT OF ATOMIC ENERGY DIRECTORATE OF PURCHASE & STORES Separate item wise sealed tenders are invited from the reputed manufacturers/dealers/also from firms registered with DPS/DGS&D/NSIC or any other Central Government Department, BY THE REGIONAL DIRECTOR, MADRAS REGIONAL PURCHASE UNIT, DIRECTORATE OF PURCHASE AND STORES, DEPARTMENT OF ATOMIC ENERGY, VI FLOOR, SHASTRI BHAVAN, 4 HADDOWS ROAD, CHENNAI600 006, for the supply at Central Stores, HWP, Tuticorin/Indira Gandhi Centre for Atomic Research, Kalpakkam- 603102, as detailed below. TENDER NO DPS/ MRPU/ IGCAR/ MIA/ 6719/ PT-1636 COST OF TEN DER (INC LUSI VE OF TAX) 525 LAST DATE FOR SALE OF TENDER SET LAST DATE FOR RECEI PT OF TENDER (1300 HRS) DATE OF OPENI NG OF TEN DER (1100 HRS) EMD (INR) 19/02/ 15 05/03/ 15 06/03/ 15 160612 SPECIFICATION AND QUANTITY Dielectric Impedance Spectrometer (Detailed specification and quantity are given in the tender document which can be purchased from Deputy Controller of Accounts, Madras Regional Accounts Unit, Department of Atomic Energy, VI Floor, Shastri Bhavan, 4 Haddows Road, Chennai 600 006 by paying the cost of the tender) The Documents priced as above can be obtained in person from the above address between 10.00 a.m. And 1.00 p.m. on all working days on submission of a written request in the firm’s letter head along with an account payee DEMAND DRAFT or Banker’s cheque drawn in favour of Deputy Controller of Accounts, Madras Regional Accounts Unit (no MO, cash or postal order acceptable), payable at Chennai. Wherever the tender documents are required to be sent by Post at Vendor’s risk, a written request for the same along with an Account Payee Demand Draft towards the tender fee, shall be sent to the Deputy Controller of Accounts, Madras Regional Accounts Unit at the above address indicating the details of the tender No., Name and address of the firm on whose favor the tender documents are to be issued. It must be ensured that such request should be sent in advance to reach this Directorate at least 10 days prior to the last date for sale of tender. The envelope should be super scribed with the wordings “Request for issue of tender document against Tender No._________________”. Alternatively prospective bidders can download the set of Technical Specifications along with the, instructions, terms and conditions, from the web link mentioned below and submit the completed format along with applicable tender fee, EMD and all applicable documents much before the due date of tender opening. However in the case of two part tenders, bidders can submit their Part-I and Part-II offers in separate covers (size: S-8) in different colors, in sealed envelopes/wrappers, by clearly and legibly super-scribing the appropriate Part Number of their offers in bold letters and the covers have to be kept in a single cover which is also to be superscribed with TENDER REF No. & DUE DATE, and submitted accordingly. Link for downloading Standard Tender Annexure: http://www.igcar.gov.in/tenders For all indigenous contracts FORM DPS-P 11 and for all Imported contracts FORM DPS-P.12 may be downloaded as the case may be from http://www.dpsdae.gov.in/StdTenderForms.asp The tenderer shall submit along with the tender, Earnest Money Deposit (EMD) as mentioned above in the form of Demand Draft or Banker’s Cheque from any Nationalized / Scheduled Banks drawn in favor of Deputy Controller of Accounts, Madras Regional Accounts Unit, Chennai. Any offer not accompanied with the EMD shall be rejected summarily as non-responsive. The EMD of the unsuccessful bidders shall be returned within 30 days of the end of the bid validity period. The same shall be forfeited if the tenderers withdraw their offer after the tender opening during the bid validity period. The Government shall not be liable for payment of any interest on EMD or any depreciation thereof. However, those who have valid registration with DGS&D, NSIC or DPS as on the date of submission of bids are exempted from payment of EMD. Brief information about our public tender is also available at http://www.igcar.gov.in/tenders and http://tenders.gov.in/department.asp?id=256. For terms and conditions, instructions please visit http://www.dpsdae.gov.in REGIONAL DIRECTOR, MADRAS REGIONAL PURCHASE UNIT HAS THE RIGHT TO REJECT ANY OFFER IN PART OR IN FULL WITHOUT ASSIGNING ANY REASON. REGIONAL DIRECTOR ========== ANNEXURE TO TENDER NO. DPS/MRPU/IGCAR/MIA/6719/PT-1636 1. Description of the ITEM : Dielectric Impedance Spectrometer. 2. Detailed SPECIFICATIONS and Quantity : Description of items Dielectric Impedance Spectrometer. End use: For characterizing the electrical conductivity, complex dielectric permeability and tanδ of piezoelectric materials at UGC – DAE consortium, Kalpakkam node. The specification of the dielectric impedance spectrometer is given below: Essential features of dielectric impedance spectrometer are given below: A. Main system involving the following specification: 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. Qty: 1 set Frequency range: 3 µHz – 40 MHz Signal amplitude: 7 Vrms DC bias: ± 40 V Current measurement: 10 fA – 100 mA -4 -3 Tanδ range: < 10 – 10 . Impedance range: 100 mΩ – 300 TΩ Capacitance range: 0.01 pF to 1F Software: Software package for acquiring, analyzing and complete automated operation of the instrument (including control of temperature in the sample cell). (Annexure 1 ) * * * * Quantities to be measured: Z , Y , ε and C (real, imaginary, magnitude, phase and tanδ). Parameters plotted: Frequency, time, bias and ac level on Bode complex plane. Power supply: 230V AC, 50 Hz. Power consumption: 30 VA max. o Operating temperature range: 20-35 C Manuals: Necessary operating and service manuals shall be provided. B. Accessories 1. Furnace with temperature controller facility (Annexure 2): o Temperature range of operation: Room temperature – 1200 C Qty: 1 No: 2. Suitable controller for the furnace (Annexure 3): o o Ramp rate: 1 C/min – 10 C/ min Qty: 1 No: 3. Sample holder facility to load the sample for measurement Qty: 1 No: (Annexure 4) 4. The working of the temperature controller must be fully automated through the software. 5. Suitable data acquisition cables, good quality BNC connections and GPIB to USB interfaces for proper acquisition and analysis of the data Qty: 1 set 5. Suitable PC for display of data Qty: 1 set C. Spares: Necessary spares (including heating filament) and tools (specifically if any) for trouble free operation for at least five years may be quoted. NB: The data acquisition, analysis and temperature control should be done with full automation through the CPU. Annexure 1: The equipment shall also have the following software capability (item A (9)) • • • • • • • • • • Capability to apply and measure- DC Voltage and current along with AC sine wave Should be able to Sweep Freq, Amplitude in both current and voltage mode. Should be able to sweep DC voltage and current Gain, phase, group delay and impedance measurements should be possible. Displays a,b,r,q,t,Z,R,X,Y,G,B,L,C,Q,D,D% Z*, Y*, ε*, C*, tan delta, DC bias, temperature should be measured and displayed against any of these parameters on Bode & Complex plane Equivalent circuit/modeling techniques for detailed analysis of results. Software should have comprehensive synchronized control on instrument and temperature controller data acquisition. Software should be capable to calculate tan delta, epsilon, permittivity, relative permittivity, impedance, admittance and other related parameters instantly. Null, normalize and auto-impedance modes 2: Essential features for item in B (1) High temperature furnace Maximum achievable temperature Maximum continuous operating temperature : : Heating element Heating rate : : Cooling rate ( cooling using air only) : Accuracy of temperature inside the chamber : 1200oC 1200oC (at 1200oC for minimum period of at least 12 hours) Molydenum Disilicide 1oC/ minute (minimum) * 15oC/minute (maximum) * 1oC/ minute (minimum) * 15oC/minute (maximum) * ± 0.5oC at all the set temperature Power rating Power supply : : ~ 5 kW 230V, 50 Hz, single phase Additional essential features 1. The furnace shall be insulated by multi-layer insulation made of high grade Al2O3 / Zircar board 2. The heating filament shall have high temperature shock resistance to open the furnace even in hot conditions. 3. The furnace shall be mountable on a bench top. 4. The furnace shall be provided with waste gas outlet on top side of the furnace with proper connections and insulations. 5. The furnace has to be supplied with additional three sets of B-type thermocouple. 6. The furnace should withstand various ambience used in measuring the dielectric impedance parameters. 3: Essential features for item B (2): The furnace shall be provided with a built-in temperature controller, whose essential features are given below: Controller of heating filament Thermocouple Display Key operation No. of program : : : : : Thyristor B type 4-5 digit display with set and actual value Simple straightforward operation with clear text display 10 programs with minimum 8 segments individually programmable. * The specified heating rates must be supported with necessary proof from the functioning of the furnace 4: Essential feature of sample holder facility item B (3) The sample holder facility should have the following features: • Sample cell should withstand the controlled atmosphere condition like vacuum, inert gases, reactive gases, moisture, etc. • The temperature control should be automated through a suitable computer with proper interfaces from the sample cell assembly. • The high temperature sample cell must be made of platinum electrodes to withstand high temperature. • Max sample dimension to be loaded: diameter – 20 mm, thickness – 5 mm. (A.M. NAGARAJAN) Asst. Purchase Officer

© Copyright 2026