Comparative study of phosphate removal from wastewater using

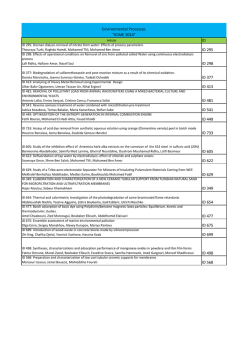

COMPARATIVE STUDY OF PHOSPHATE REMOVAL FROM WASTEWATER USING CHEMICAL PRECIPITATION METHODS V. Tsamili, M. Mitrakas Department of Chemical Engineering, Aristotle University of Thessaloniki, Thessaloniki, 54124, Greece Keywords: wastewater, chemical precipitation, MgO, Ca(OH)2, CaMg3(CO3)4, FeClSO4 Presenting author email: [email protected] ABSTRACT Phosphorus is one of the main elements contributing to the pollution of aquatic populations, favoring eutrophication. Reducing the amount of phosphorus flowing in industrial waste on the environment is an important step towards its protection. The purpose of this study is to investigate the removal of phosphate ions from industrial wastewater in the process of chemical precipitation. Specifically, in this work, the effect of pH and of the dose of electrolytes MgO, Ca(OH)2, CaMg3(CO3)4 and FeClSO4 that achieve low residual concentration of phosphate ions was studied. Experimental results showed that: Huntite was quite effective, as the concentration of PO4-3 decreased up to 82.4% (addition of 0.5 g/L), without affecting the process conditions, while the system was stabilized in a relatively short time (30 min). The use of magnesium oxide was also satisfactory because the PO4-3 concentration decreased up to 80.3% (addition of 0.5 g/L), the pH of the process was in the range 7.5-8.5 after 60 min. However, the increase of pH of the process is considered a disadvantage. Hydrated lime was also effective, but there was an increase of the pH value of the process. The concentration of PO4-3 decreased up to 35.5% (addition of 0.5 g/L) at neutral pH, while achieving lower residual concentration of PO4-3 caused problems in the process (i.e., increase of the pH). The use of Fe+3 was highly effective, and showed complete removal of the PO4-3 in a short time (10 min) and even with the addition of a minimum quantity (1 g Fe+3/L in a concentration of 1000 mg PO4-3/L ) but lead to a significant decrease in pH of the solution in the range of 1.5-2.0 which necessitates the recovery of the range of 7.0-8.0. For the application of this process on an industrial scale based on the experimental results, the use of huntite or hydrated lime is the most appropriate; the processes proved efficient and with minimal or no defects. However, between these two techniques, the use of huntite was more efficient than that of hydrated lime in each case. INTRODUCTION The removal of phosphorus takes place for control of eutrophication since phosphorus is a limiting nutrient in most aqueous systems. Due to the limited presence of inorganic phosphate in the aqueous environment, often only in traces, the phosphorus is very often the limiting factor for plant growth, in comparison to the nitrogen. Therefore eutrophication is based on the first phase in the presence of increasing phosphate and removing them from the environment and indirect means reducing the negative effect of the other elements. [1] Phosphorus occurs in liquid waste from urban, commercial and industrial activities. The industrial and commercial sources of phosphorus are highly variable and may affect much the actual inflow concentration of phosphorus in the wastewater. The removal of phosphorus from the wastewater requires the transfer of phosphate from the liquid form to a solid form, followed by a process of solid-liquid separation and at the end the removal of phosphorus with the excess sludge. The chemical precipitation aimed to convert the phosphorus to form a solid, is the most enhanced biological phosphorus removal. Both techniques require the efficient separation of liquid/solids to minimize the total phosphorus concentration. The use of technical chemical waste treatment for phosphorus removal displays the following advantages [1]: • not increase in the salinity of the aquatic environment • the buffering capacity is increased • the quantity of sludge is reduced. The chemical treatment for removing phosphorus comprises the addition of metal salts which react with the soluble phosphorus and form solid precipitates phosphate removed by procedures for separating solids from liquids such as clarification and filtration. The phosphate precipitation is achieved by the addition of metal salts which form insoluble phosphate compounds. [1] Today, the main commercial process for removal of phosphate from waste is chemical precipitation using aluminum, calcium, magnesium or iron. Usually the removal of phosphate is combined with the precipitation of ammonium ions. Research that has been conducted involving the use of MgO [2], ion Mg+2 [3], Ca(OH)2 [4], Fe+2 ions by adding H2O2 [5], ion Fe+3, wherein the phosphate ions are removed ως FePO4·2H2O [6], dolomite [7] and other compounds as flocculants. EXPERIMENTAL During the experimental procedure, was studied the way that the conditions of pH, reaction time, kind of electrolyte, and the ratio of reactants affecting precipitation of PO4-3, in a discontinuous process of gentle agitation. The liquid waste was simulated with aqueous solution of a given concentration PO4-3. Materials, devices and instrumentation of the experimental procedure are reported in Table 1 below. PO4-3 source Electrolytes Indicator Table 1. Equipment of experimental procedure Reagents Equipment KH2PO4 (s) BATCH reactor Ca(OH)2 (s) Filtration device MgO (s) Glass cell (1 cm) CaMg3(CO3)4 (s) pH electrode FeClSO4 (aq) (12,5% w/w) Spectrophotometer UV-Vis Vanadate-Molyvdate Initially was determined the reaction time required for each electrolyte to establish balance in the system. In a second step we studied the effect of varying the pH removing PO 4-3. For each case of electrolyte was added an amount equal to 0.5 g / L at a given initial concentration of PO4-3 solution equal to 1000 mg / L and observed system behavior at increasing pH values in the range 7.0-13.0 (using NaOH). As a third step, we investigated the way that the ratio between the initial concentration of PO4-3 solution and the added quantity of each electrolyte affects the efficiency of the process. In this case, in a solution of the initial concentration of PO4-3 equal to 1000 mg/L, was added, in separate tests, a quantity of electrolyte equal to 0.5, 1.0 and 1.5 mg / L (1.0, 2.0 and 3.0 in the case of FeClSO4), by results suggested that the optimal ratio for each electrolyte. Briefly, the steps for the completion of the experimental procedure, except for the stage of the reaction was sampled, filtering, sample processing and the spectrophotometric determination of residual concentration PO4-3. By the diagram of Fig.1, the reaction took place in batch reactor under conditions of gentle agitation, wherein the removal of PO4-3 was perceived by creating precipitate during the reaction (Step S1). Then, a sufficient amount of sample was obtained from the editorial volume of solution, which was filtered to remove particulate matter from it, to avoid deterioration of the results (Step S2). The filtrate was treated properly to be feasible spectrophotometric determination of the concentration of PO4-3. During this processing, in 10.0 ml of filtrate was added 1.0 ml of the indicator Vanadate-Molyvdate (Step S3). In the solution was developed a yellow color to stabilize which required at least 10 min and its intensity to the concentration reveals PO4-3. Finally, the residual PO4-3 concentration of the sample was determined spectrophotometrically (Step S4). [8] A prerequisite is to obtain the curve before the experimental procedure. For this purpose, standard solutions of 0.0, 5.0, 25.0, 50.0 and 100.0 mg PO4-3/L, were used, which were treated similarly with the sample. As wavelength is proposed a value within the range 430-490 nm for determining the concentration of phosphate ions. [8] Fig.1. Experimental procedure for removal and identification PO43- RESULTS AND DISCUSSION The calibration curve was determined before each experimental procedure. As wavelength for spectrophotometric determination of the concentration of PO4-3 , initially to construct the calibration curve, were selected 450 nm, which is part of bibliographic range of 430-490 nm is used [8] and proved the most appropriate for the specific length wavelength curve shows the smooth and straight form y = Ax + B, as shown in Fig. 2. 0,35 y = 0,0032x + 0,0079 R² = 1 λ=450 nm 0,30 0,25 A 0,20 0,15 0,10 0,05 0,00 0,0 25,0 50,0 PO43-, 75,0 100,0 mg/L Fig. 2. Calibration curve for PO4-3determination Next step was the determination of tr. Figure 3 shows the time, tr, which was required in each case an electrolyte to complete the precipitation reaction time, by varying the residual concentration PO4-3. Fig. 3. Residual concentration of PO43- as a function of tr It was observed that the use of Ca(OH)2 was quite effective because removed enough phosphate precipitation and the reaction was carried out within 30 min. A similar result was observed in the case of huntite and , where the huntite displayed relatively better performance than this of the Ca (OH)2 for the same reaction time. The use of MgO also proved more effective in the removal of PO 4-3, but less effective with the corresponding case of Ca (OH)2 and huntite, for the same reaction time (30 and 60 min). Disadvantage of this method however is the long reaction time required (about 150 min). This happens due to the time needed for the conversion of MgO to the corresponding hydroxide by the reaction with water and then the action in a manner similar to that of Ca(OH)2. The use of FeClSO4 was proved as highly effective, wherein PO4-3 ions are completely removed from the solution in a fairly short time, only 10 min. Significant drawback of the method however is the dramatic reduction of pH with the use of this instrument and the electrolyte using NaOH necessary to increase the value of the region 7.0-8.0. Fig. 4 shows the change of the residual concentration of PO4-3 as a function of the pH for each electrolyte used, with samples that taken directly to the set point pH. General observation based on these experimental results is the fact that the efficiency of the process increased with rise in the pH. In the case of adding Ca (OH)2 and huntite, the initial pH of the solutions was not affected (remained practically equal to 7.0) is therefore to increase the pH was necessary to use NaOH. In comparison, the use of huntite proved more effective in removing PO4-3 against the use of Ca (OH)2. In case of using MgO, because of long reaction time that is required, as mentioned, the action of the particular electrolyte studied for 150 min without the addition of NaOH to increase the pH. It was observed that the addition of MgO increases the pH value of the solution with time, is stabilized at pH=9.79 after 150 min. The behavior of this process is similar to the previous two, where it was observed that increasing the price of pH favors the removal of PO4-3. The study of the behavior of the process using FeClSO4 at high pH values was not necessary, as completely removed the PO4-3 at pH≈7. Fig. 4. Residual concentration of PO43- as a function of pH Finally, it was studied the way in which the amount of electrolyte added affects the efficiency of the process, maintaining a constant initial concentration of PO4-3 in the solution for a given reaction time. For each case of electrolyte, the experimental results are presented in Tables 2-3. -3 PO4 (initial), mg/L pH (initial) Electrolyte, g/L Table 2. Process response using MgO or Ca(OH)2 MgO Ca(OH)2 Test 1 Test 2 Test 3 Test 1 Test 2 1000 1000 1000 1000 1000 6.30 6.30 6.30 6.37 6.37 0.5 1.0 1.5 0.5 1.0 tr, min PO4-3 (residual), mg/L pH (final) 30 859.7 7.52 30 608.2 8.52 30 129.4 10.21 tr, min PO4-3 (residual), mg/L pH (final) 60 197.2 7.53 60 132.0 8.58 60 11.8 10.21 PO4-3 (initial), mg/L pH (initial) Electrolyte, g/L tr, min PO4-3 (residual), mg/L pH (final) 30 582.6 7.05 30 299.0 9.81 Table 3. Process response using CaMg3(CO3)4 or FeClSO4 CaMg3(CO3)4 FeClSO4 Test 1 Test 2 Test 3 Test 1 Test 2 1000 1000 1000 1000 1000 6.31 6.31 6.31 7.50 8.01 0.5 1.0 1.5 1.0 2.0 30 200.0 6.50 30 200.0 6.55 30 168,8 6.65 30 0.0 7.54* 30 0.0 8.13* Test 3 1000 6.37 1.5 30 0.9 12.57 Test 3 1000 7.62 3.0 30 0.0 7.71* tr, min 60 60 60 PO4-3 (residual), mg/L 198.2 191.1 159.8 pH (final) 6.61 6.68 6.98 * maintenance of the pH in the range 7.0-8.0 using NaOH Based on the results in Table 2 and in conjunction with Fig. 2, at first the conversion of MgO to the corresponding hydroxide takes place, by interaction with water, which is responsible for the removal of the PO4-3. The concentration of PO4-3 can be reduced up to 80.3% (addition of 0.5 g/L) while the pH of the process is in the range 7.5-8.5, after 60 min. In the case of using Ca(OH)2, the removal of the PO4-3 is carried out rapidly and can be reduced up to 35.5% (addition of 0.5 g/L) in the region of neutral pH, while the minimum residual concentration is efficient at pH≈13. Based on the data of Table 3, the removal of the PO4-3 using CaMg3(CO3)4 is quite effective in a short time (30 min) without affecting the pH of the process, where the concentration of PO4-3 is reduced up to 82.4% with the addition of less quantity of electrolyte, i.e. 0.5 g/L. In case of using FeClSO4, removal PO4-3 was completed in a short time even with a minimum amount of the electrolyte tested (1 g/L), however, the major disadvantage of the rapid pH reduction, necessitates the use of NaOH for the pH maintenance in the region 7.0. In each case of electrolyte, the proposed amount added corresponds to 0.5 g/L, in the case of MgO is also proposed the ratio of 1.0 g per L of electrolyte solution and in the case of FeClSO4 the ratio of 1.0 g/L. These ratios are proposed as an adequate effect to remove PO4-3 while having only a few or any disadvantages. CONCLUSIONS The use of huntite seems to be the most efficient because it presents several advantages. The addition does not affect the pH conditions of the solution at any time (it remains practically constant in the range 6.5-7.0) where there is up 82.4% removal of PO4-3(addition of 0.5 g/L), a short reaction time (maybe less than 30 min) is required to stabilize the process. PO4-3 are removed due to the formation of compounds of magnesium and calcium, two kinds of precipitates, Mg3(PO4)2, and Ca10(PO4)6(OH)2. The use of MgO has similar behavior, with the disadvantage that the required reaction time for the stabilization of the process is at least 5 times greater than the corresponding use huntite. This is due to the conversion of MgO to the corresponding hydroxide, during its interaction with the water and then the reaction with PO4-3: MgO + H2O Mg(OH)2 (1) 3Mg(OH)2 + 2H3PO4 Mg3(PO4)2↓ + 6H2O (2) The concentration of PO4-3 is reduced up to 80.3% (addition of 0.5 g/L), with the pH of the process be in the range 7.5-8.5, after 60 min. Disadvantage of the method can also be regarded the increase of the pH about one unit with the addition of this electrolyte. Also efficient was proved the use of Ca(OH)2, wherein PO4-3 ions are removed in accordance with the equation: 10Ca(OH)2 + 6H3(PO4) Ca10(PO4)6(OH)2↓ + 18H2O (3) The process appears to be effective because it presents almost the same advantages with the use of huntite, but an increase of the pH while the reaction is in progress and the concentration of PO4-3, although it was reduced, in each case was higher than corresponding to the use case huntite (reduction up to 35.5% with addition of 0.5 g/L). Finally, in the case of FeClSO4, removal PO4-3 is complete even with the addition of minimal amounts, according to the equation: FeClSO4 + H3PO4 FePO4↓ + HCl + H2SO4 (4) The required time for the completion of the reaction is 10 min, even at pH=7.0. Despite the effectiveness of the technique, there is a major disadvantage, the pH reduction of the solution during the addition of the electrolyte in the range 1.5-2.0. Therefore, it is necessary to use NaOH to increase the pH value in the range 7.0-8.0. In each case of electrolyte, the proposed amount added corresponds to 0.5 g/L, in the case of MgO is also proposed the ratio of 1.0 g per L of electrolyte solution and in the case of FeClSO4 the ratio of 1.0 g/L. REFERENCES [1] P. Melidis, Designing, operating problems, optimization and process control: Phosphate removal (2012) [2] J.M. Chimenos, A.I. Fernández, G. Villalba, M. Segarra, A. Urruticoechea, B. Artaza, F. Espiell, Removal of ammonium and phosphates from wastewater resulting from the process of cochineal extraction using MgO-containing by-product, Water Research, 37(7) (2003) 1601-1607 [3] S. Uludag-Demirer, M. Othman, Removal of ammonium and phosphate from the supernatant of anaerobically digested waste activated sludge by chemical precipitation, Bioresource Technology, 100(13) (2009) 3236-3244 [4] K. Hosni, S. Ben Moussa, A. Chachi, M. Ben Amor, The removal of PO43− by calcium hydroxide from synthetic wastewater: optimisation of the operating conditions, Desalination, 223(2008) 337-343 [5] C. Li, J. Ma, J. Shen, P. Wang, Removal of phosphate from secondary effluent with Fe2+ enhanced by H2O2 at nature pH/neutral pH, Journal of Hazardous Materials, 166(2-3) (2009) 891-896 [6] T. Zhang, L. Ding, H. Ren, Z. Guo, J. Tan, Thermodynamic modeling of ferric phosphate precipitation for phosphorus removal and recovery from wastewater, Journal of Hazardous Materials, 176(1-3) (2009) 444-450 [7] H. Roques, L. Nugroho-Jeudi, A. Lebugle, Phosphorus removal from wastewater by half-burned dolomite, Water Research, 25(8) (1991) 959-965 [8] American Public Health Association, Standard Methods for the Exams of Water and Wastewater, Washington, DC., 1989

© Copyright 2026