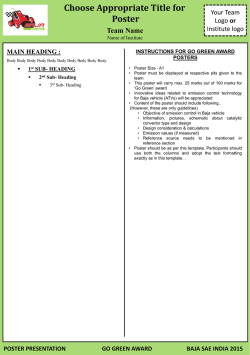

On “Sustainable Solid Waste Management in India