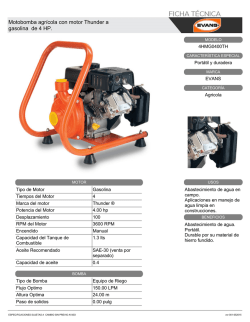

6 - bomba sultana